Medical Precision Grinding

Many medical components require surface and centerless grinding to precisely reduce the size, shape, or finish of components. TE employs multiple processes, configurations, and orientations to satisfy simple and complex grinding requirements with extreme accuracy and speed.

Precision grinding allows small-dimension parts to fit and function together in complex, tight-tolerance devices. TE is at the forefront of grinding technologies and offers advanced methodologies to grind parts made from solid and tube stock.

Electrochemical grinding

Electrochemical grinding is a highly suitable option for small, intricate parts because it diminishes the size or existence of burrs that often accompany conventional methods. TE features electrochemical grinding that combines electrolytic action and abrasive grinding for a precise, burr-free output. Our low-stress operation minimizes contact to avoid potential cracking, heat distortion, and other metallurgical damage often found when using conventional grinding machines.

Our process is limited to metals that are conductive, such as stainless steel, titanium, nickel alloys, nitinol, copper, and aluminum. Using fixtures produced in-house, we can hold tolerances of ±0.001” (0,0254 mm).

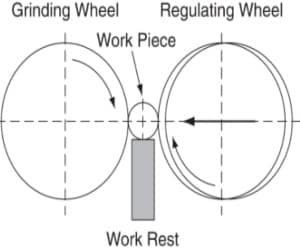

Centerless grinding

Centerless grinding is a spindle-free method that removes outside material from a part while maintaining its specific diameter and shape. TE uses a variety of grit wheels to grind standard ID-size stock down as a cost-efficient route to creating custom OD tube sizes for customers. Depending on raw material starting size and composition, we can offer tolerances as tight as ±0.0002” (0,0508 mm), wall thicknesses as small as 0.0015” (0,0381 mm), and OD surface finish as smooth as 6 Ra.

CNC grinding

The pointed tips used in medical applications must have precise edges and flawless surfaces to maximize patient comfort. TE employs a broad range of geometric techniques to produce tips for:

- Trocars: feature a three-sided grind on solid wire, with grinds generally oriented 120° degrees from one other

- Lancets: consist of two-side grinds on a triple-ground needle

- Custom complex needle tips: including five-sided grinds on complex cutting tips

We also have the capability of utilizing CNC grinding technology to remove outside material on wires and rods:

- Multi-tapers

- High-complexity grind profiles

- Ground length tolerances > +/-0.005” (0,127 mm)