Overcoming the Design Challenge: Faster, Safer EV Charging Stations

Rapid advances in EV infrastructure technologies are moving the industry toward better solutions for enabling sustainable electrified mobility.

The current dilemma is quite obvious: On the one hand, customers are less likely to purchase an electric or plug-in hybrid vehicle if they lack confidence in the infrastructure needed to support large-scale EV charging. On the other hand, a stagnant EV market means that companies and municipalities are investing less in charging infrastructure to drive the technology forward. It resembles the classic “chicken or egg" problem.

There are major obstacles to the expansion of e-mobility. Thankfully, engineers, technology companies, government agencies and other organizations are working together to solve some of the most complex challenges standing in the way of widespread, global implementation of EV charging networks.

Several areas of innovation hold promise for the future of EV charging infrastructure, including solutions for higher voltages and current, components that support miniaturization, and improved thermal management techniques. TE Connectivity works closely with engineers to design and develop EV charging solutions that meet the specific needs in different regions and meet the universal, growing demand for higher current and voltage.

Higher Voltage and Current with Improved Thermal Management

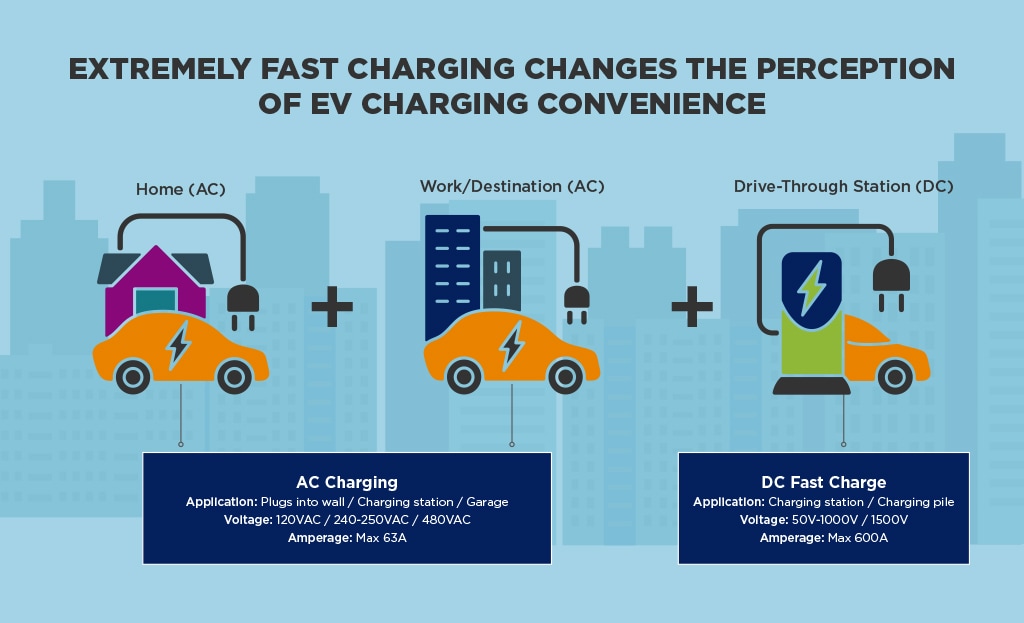

One of the biggest challenge to widespread adoption of electric vehicles is the charging speed. Currently, fast-charging stations can charge up to 80% in 20 to 30 minutes, offering the most promising alternative to traditional gas stations. The increasing number of fast charging stations available and the charging speed they offer pose growing challenges for engineers.

Fast charging stations must be designed for high power output and wide-ranging current regulation, as higher current and voltage demands are imposed here. This requires the selection of high-quality, reliable components that can safely connect and protect the flow of power throughout the EV. Relays and contactors designed for higher power ratings, for example, contribute to reliable charging circuit design and solid protection in fast charging mode.

Handle the Current without Overheating

Charging systems built for higher voltages and currents increase the thermal load on the EV system, which increases the temperature of the battery and all connecting components between it and the charger.

It therefore must be ensured that each component is dimensioned so that it can carry the rated current without overheating. However, they should not be oversized so as not to increase the overall weight of the system, misallocate limited space, or add unnecessary costs. Liquid cooling techniques can also be applied to allow the charging cable to handle the current required for fast charging speeds without overheating.

To address the issue of thermal loads and ensure the specification of properly sized and highly reliable component solutions, TE Connectivity has developed advanced thermal modeling techniques that can be used to analyze the performance of internal connections and components exposed to elevated temperatures during charging. These techniques enable safe and reliable performance in EV charging systems.

Miniaturization of Onboard Chargers and Charging Stations

It is important that the charging infrastructure not only becomes faster and more powerful, but also smaller and lighter, so that the global expansion of the EV charging network can continue to progress. Increasing the power performance of the charging technology while reducing its size naturally presents engineers with significant challenges.

When developing AC and DC charging stations, size and weight in particular should be taken into account. Designing AC chargers small and light will save space in the vehicle. This applies to both home and public charging stations: They need to be as small as possible to maximize available space, especially in urban areas where space is limited.

Key components in EV chargers include board and signal connectors, contactors, power resistors and terminal blocks. If these components can be miniaturized, the industry will have the opportunity to develop more compact and flexible charging solutions. However, it is important to ensure that the performance required for faster charging speeds is not compromised as these components become smaller.

Together with TE, engineers and designers can empower the future of e-mobility infrastructure. More information about TE Connectivity´s solutions for energy efficient, faster charging applications: EV Charging

e

e

e

e

e

e