Integrate circuitry in small spaces

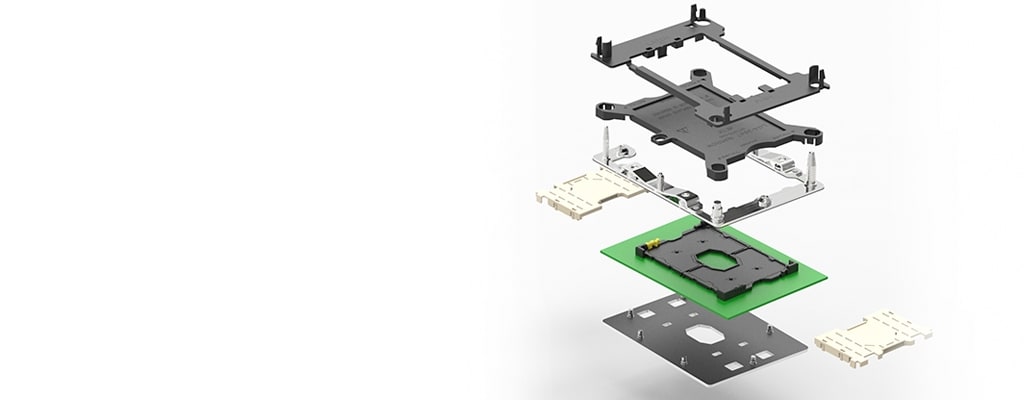

Our Land Grid Array (LGA) sockets are often used in high performance computing, servers, workstations, and desktop computers. LGA sockets can provide compressive electrical interconnect between the printed circuit boards (PCBs) and the processor.

With decades of experience in socket evolution, we offer a vast array of sockets to support various applications. We have specialized various socket technology – dual inline pin (DIP), pin grid array (PGA), micro PGA (uPGA), and LGA – since 1970. We provides technical excellence in socket designs and works very closely with customers in the development of compression hardware. We share our expertise through finite element analysis (FEA), signal integrity, and tolerance analysis. Our portfolio includes different LGA contact technologies, depending on customer requirements. This includes hybrid contacts, dual compression contacts, and conductive polymer columns.

For more than 15 years, we have been developing socket hardware. We offer a wide range of development capabilities, including internal load mechanism, general compression hardware, and hardware-integrated thermal solutions. Our socket hardware supports system structural simulation using, for example, ANSYS tools, which normally includes full assembly stack up: backerplate, host board, socket, package, and loading system; and package detail required to assess mechanical stresses in package. Our hardware can commonly support single load or multi-load systems.

If you are looking for a different approach with a faster turnaround time, our extra large array (XLA) socket technology may be a solution for you. The main difference between an XLA socket and a traditional LGA socket is that our XLA socket utilizes a PCB substrate instead of a molded plastic housing.

Capital and lead time tend to be less for the XLA socket since a traditional housing is normally not needed. The main advantage of the XLA socket over a traditional LGA socket is that there is commonly a 33% better true position and 78% better warpage control.

We offer two types of XLA sockets: dual compressive and hybrid. The dual compressive socket has an LGA/LGA design, with contacts on the top and bottom of the PCB. It can be easier to implement, but since it has more pins there is an increased chance of pin damage. Our XLA hybrid socket is an LGA/BGA design. It can have a better attachment to the motherboard because of the BGA (ball grid array) that is soldered to the board.

In addition to our XLA sockets, we can provide traditional dual compressive and hybrid sockets. Determining the right socket technology to address customer applications requires close collaboration with engineering on mechanical and electrical requirements. We have the experience to make a helpful recommendation based on those requirements.

e

e

e

e

e

e

e

e

e

e