TE Connectivity delivers greater control in drive systems with new braking resistor assemblies

New HPBA series improves control and speed of braking in servo drive applications

04/05/2022

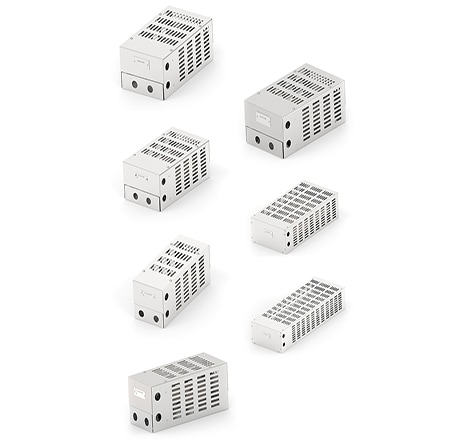

MIDDLETOWN, Pa. — TE Connectivity (TE), a world leader in connectivity and sensors, has introduced new HPBA series braking resistor assemblies to provide faster, more controlled braking in variable frequency and servo drive applications. This enables greater reliability and agility for drive systems in industrial applications, robotics and warehouse automation.

The new braking resistors support increasing demand for productivity in industrial settings. With greater control over the braking speed of their drive systems, manufacturers and warehouse operators can more quickly adjust between production runs and avoid costly downtime.

“The type HPBA series addresses a growing need for braking torque capability in today’s industrial environments,” said Jesus Jimenez Santos, global product manager for TE. “These braking resistor assemblies help keep operations running smoothly in a variety of settings, from a high-mix, low-volume factory to an automotive warehouse.”

Key benefits of the HPBA series include:

Greater braking torque — The HPBA series increases the braking torque of the drive system, with 100% and 150% braking torque options available.

Improved power dissipation capability — Available in 0.5 HP – 500 HP, the braking resistor assemblies can quickly dissipate power in industrial machinery for a faster, more controlled finish.

Customizable solution — The assemblies are offered in several combinations of horsepower, input voltage and duty cycle to meet customers’ individual needs.

Built for harsh environments — Each assembly is designed with heavy gauge galvanized steel, a wired terminal block and provisions for an optional thermostat.

Media Inquires

Katie Raymond

TE Connectivity

Tel: +1 717 985 2053

Email: k.raymond@te.com

Amy Wilson

TE Connectivity

Tel: +1 717 985 2716

Email: amy.wilson@te.com