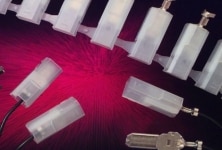

Easy wire termination with quick disconnects

Our portfolio of quick disconnect connectors or wire disconnects includes a range of sizes, materials, retention features, temperature ranges, and insulation options. Our quick disconnect terminals are engineered for flexibility and for fast and easy terminations. We also offer a variety of tools, from hand tools to fully automated applicators, to help crimp connections consistently, either for making a few connections and disconnections in the lab or for making millions on an assembly line.

Product Features:

Specifications for Quick Disconnects

- Insulated and uninsulated

- Straight and flag configurations

- Stress relieved receptacles

- Various plating options

- Positive Lock terminal solutions

- High temperature solutions

- Application tooling

Frequently Asked Questions

Q: What tab are you mating to? What is your thickness and width requirements?

A: TE Connectivity offers a variety of terminals that mate to a variety of tabs. Some width sizes include .312”, .250”, .187”, .125”, .110” and the standard thicknesses for these terminals are .032” and .020”.

Q: Do you have low insertion force requirements?

A: TE Connectivity has 8 to 16 lb. options. We offer a variety of terminals such as premier, budget, LIF, moldable and hermetic style terminals.

Types of Crimp Connects

| Crimp Type | Description |

|---|---|

| “F” Crimp | Most common crimp used on straight and flag terminals offers optimum combination of strength and conductivity. Method of termination provides maximum resistance to vibration and corrosion. |

| Tab-Lok Crimp | Featured on flag terminals. Locking tab on wire barrel is inserted through a slot on the terminal itself. |

| “C” Crimp | Featured on flag terminals. Provides reliable electrical and mechanical performance with a minimum profile. |

e

e

e

e

e

e