Consistent Quality Terminations

Our applicators are designed to deliver the next evolution in crimping technology, supporting a wide range of terminals with unmatched consistency and precision. Built from high-grade materials and engineered with optimized dimensions, the CORE Applicator Platform reduces manufacturing complexity while ensuring high repeatability and fast throughput. Listening closely to customer input and market demands, TE has innovated beyond the popular OCEAN 2.0 design, making the CORE Applicator even simpler to set up, faster to adjust, and more efficient in operation. Backed by decades of expertise in applicator and tooling design, TE is once again raising the standard of terminal crimping with the introduction of the CORE Applicator Platform.

CORE Applicator

Features and Benefits

Our new CORE applicator platform delivers consistent crimp quality while cutting costs and setup time. Compatible with OCEAN 2.0 touch tooling, it supports diverse uses from wire harnesses to HVAC and vehicle wiring. With fewer components and a streamlined strip guide, it simplifies calibration, shortens lead times, and boosts efficiency.

Key Benefits:

- Reliable, High-Quality Crimp Performance

- Faster Setup & Easier Calibration

- Lower Total Cost of Ownership

- Fits into strip seal terminators

60%

Improved ram/housing alignement

50%

Faster set-up and adjustment times

30%

Customer reported tooling life increase

OCEAN 2.0 Applicator

Features and Benefits

- Wire crimp height adjustment—provides 360° of adjustment to help minimize errors; able to adjust crimp height at 1° increments

- Easy-to-access screws for faster applicator set-up and adjustments

- Pinned base-plate design to help prevent misalignment

- Protective black nitride coating on select components

- Relocated forward-facing screws for faster/easier access to make adjustments without removing applicator from some machines

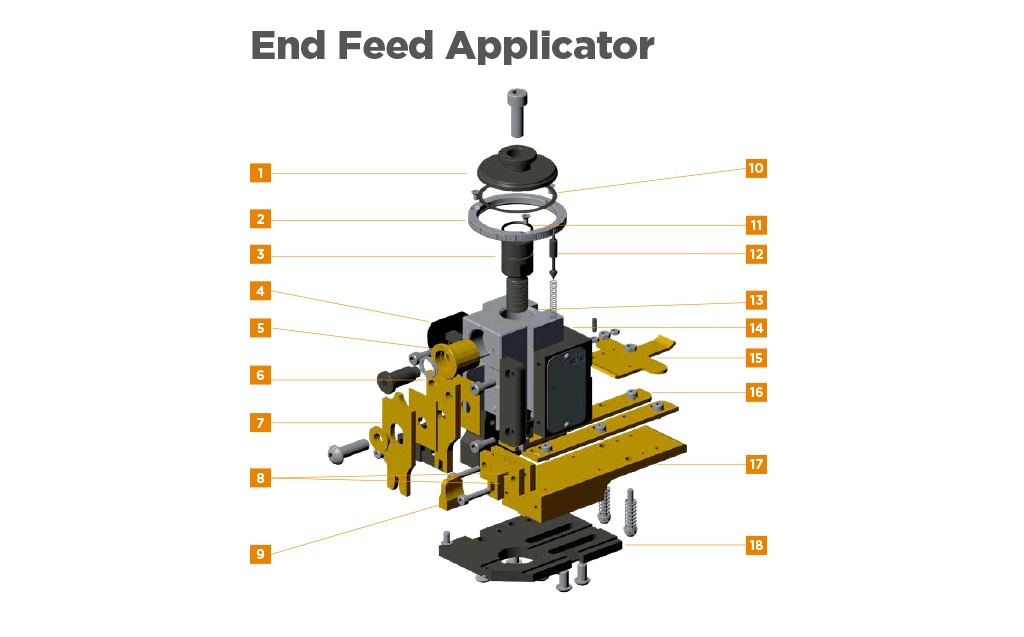

End Feed Applicator

Legend

1. Adjustment Head

2. Wire Crimp Disc

3. Adjustment Bolt

4. Counter

5. Insulation Crimp Dial

6. Wire Crimper

7. Insulation Crimper

8. Shear Plates

9. Anvil

10. Detent Disc

11. O-Ring

12. Reversible Crimp Height Adjustment Pin

13. Ram

14. Housing

15. Stock Drag

16. Strip Guide Plates

17. Strip Guide Block

18. Base Plate

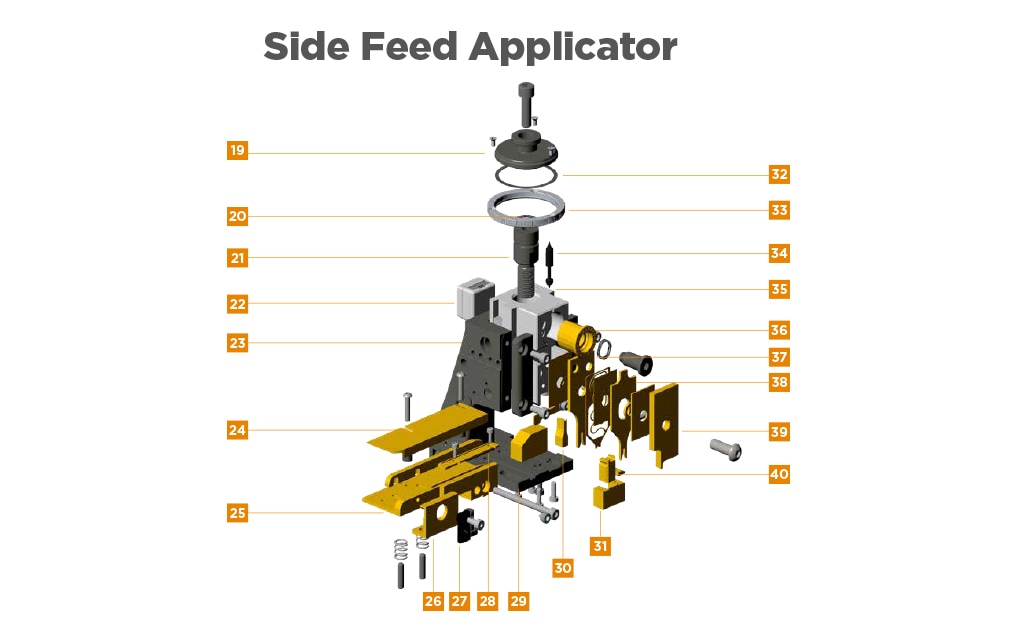

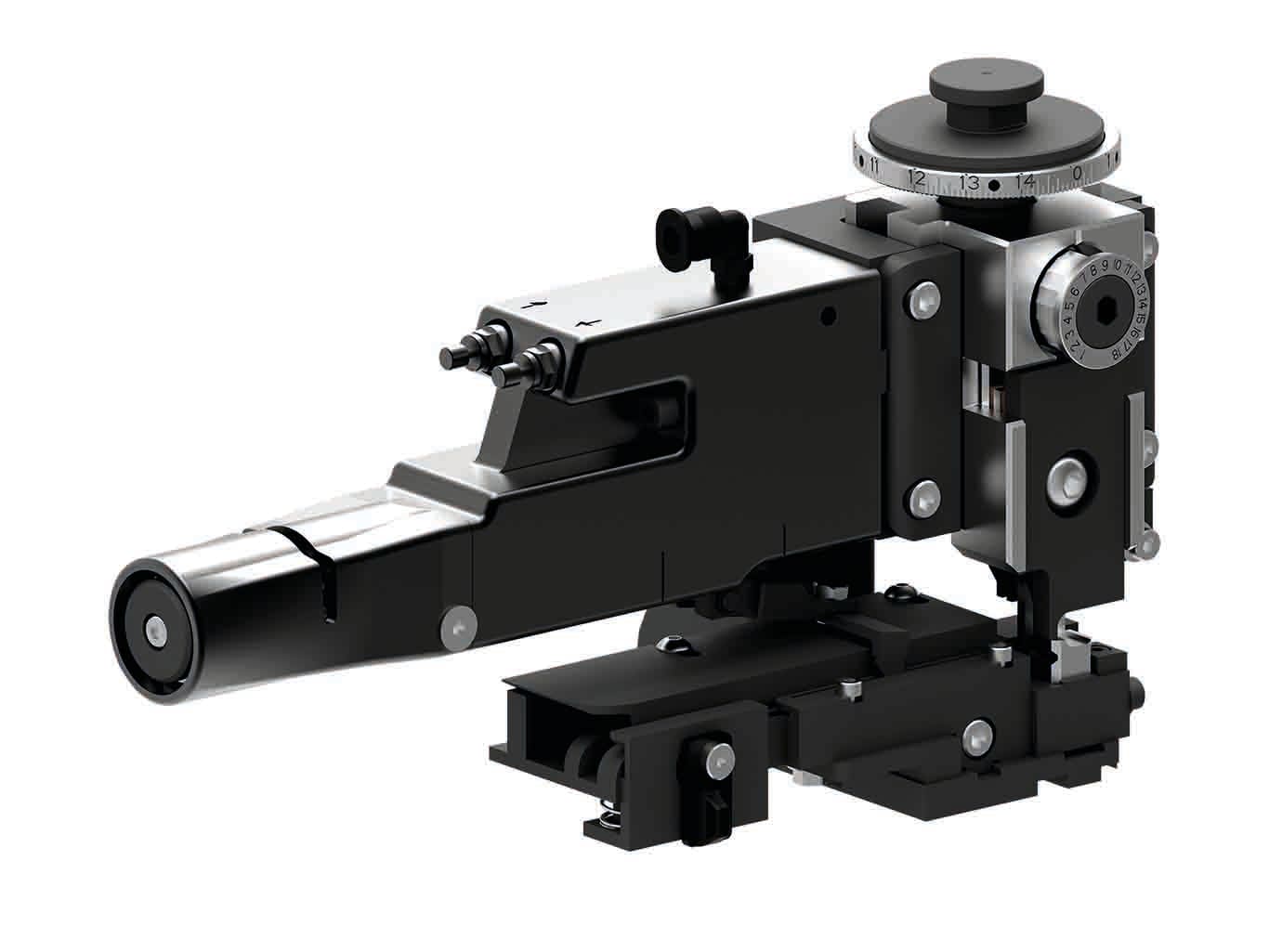

Side Feed Applicator

Legend

19. Adjustment Head

20. O-Ring

21. Adjustment Bolt

22. Counter

23. Housing

24. Strip Guide Plate

25. Strip Guide Adjustment Block

26. Stock Drag

27. Drag Release Level

28. Front Strip Guide Plate

29. Base Plate

30. Anvil

31. Front Shear Holder

32. Detent Disc

33. Wire Crimp Disc

34. Reversible Crimp Height Adjustment Pin

35. Ram

36. Insulation Crimp Dial

37. Wire Crimper

38. Insulation Crimper

39. Shear Depressor

40. Floating Shear

Two Terminal Feed Options

Mechanical Feed

Pneumatic Feed

Mechanical Feed

The cam/follower design produces repeatable feed in the industry. Independent forward/backward adjustment.

Standard Features

- Significantly improved repeatability

- Same feed module for side feed and end feed

- Single tool adjustments

- Infinite micro feed adjustment increments 1 revolution = 0.7 mm

Advantages

- Precise and repeatable terminal position over the anvil

- Independent forward and back stroke adjustment

- 50% faster adjustments compared to HDI/HDM

Pneumatic Feed

Independent forward/backward adjustments, independent flow controls, repeatable feed.

Standard Features

- Single tool or tool-less adjustments

- Same feed module for side feed and end feed

- Independent forward & back adjustments

- Micro feed adjusted incrementally with steps 0.04mm forward terminal position

- Maximum feed length: 48.25 mm

Advantages

- Independent forward and back stroke adjustment

- Adjustable speed actuation

- Self actuating

- Single or tool-less adjustment

- Single piece piston and rod assembly

- Internal exhaust valves

Style of Ram Interface

Chrome plating, specialized materials, precision tolerances and mirrored surface finishes yield up to a 30% customer-reported increase in tooling life.

60%

Did you know that most leadmakers are only producing leads 60% of the time due largely to the time it takes to switch applicators.