Battery Management Systems Connectivity

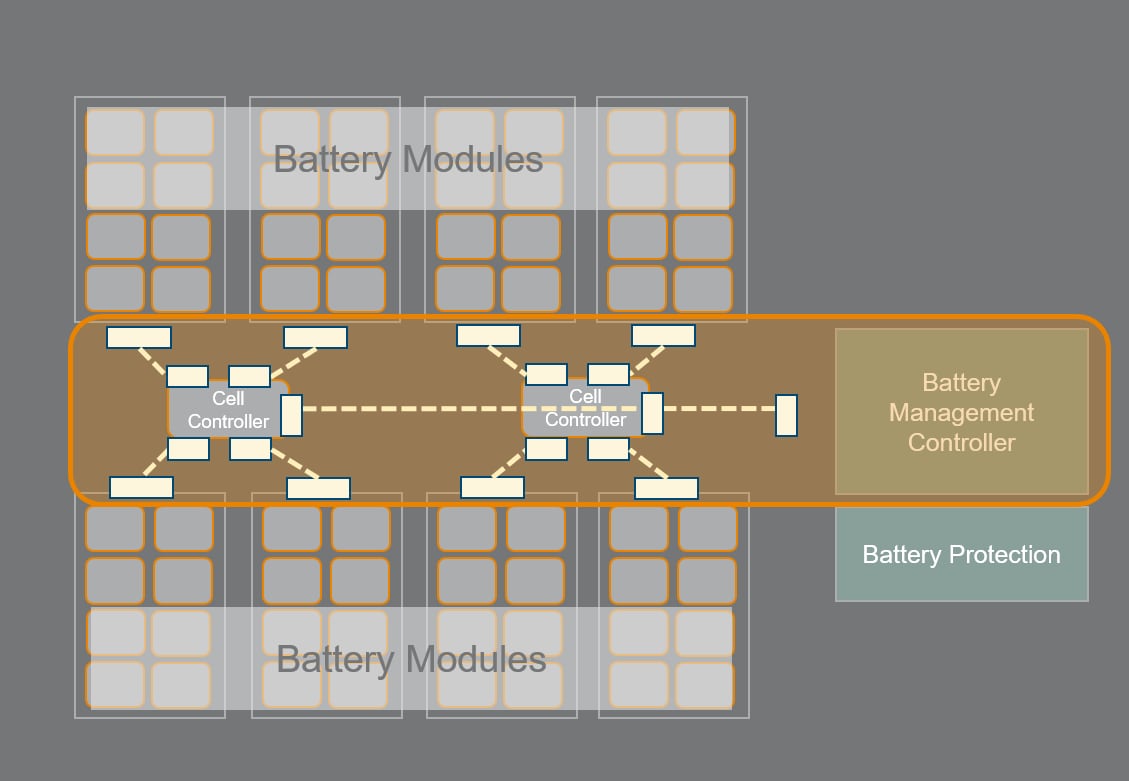

A battery management system (BMS) is the electronic system that manages the battery pack and the cells within. Its purpose is to protect the battery from operating outside its safe limits by monitoring its state. It processes collected data, communicating it to the elements that balance or control its environment.

The Battery - The Heart of an Electric Vehicle

In the same way that the internal combustion engine (ICE) was considered the heart of the traditional motor vehicle, the battery is considered the heart of electric vehicles (EVs).

The key driver of battery technology development is range but, at the same time, automotive battery engineers need to offer designs that optimize performance, in terms of power to-weight/ size, whilst also maintaining the highest levels of safety. Connectivity plays a key role in meeting this challenge.

The Role of Connectivity

The BMS must operate with a high degree of accuracy and reliability and must be of highly robust construction. However, it should also be compact and lightweight, adding the least possible bulk to the overall battery pack geometry. Therefore, BMS electronics require highly compact, yet flexible connector systems offering the flexibility to support multiple permutations of connector configurations. In addition, the connector system should offer safe “creepage” and clearance distance between the pins, ensuring no risk of failure from short circuits caused by dust pollution or arcing.

TE Connectivity Solutions for Battery Management Systems

TE Connectivity offers a range of automotive-grade, LV214 compliant solutions for electric vehicle battery management systems. Based on its MQS and NanoMQS miniaturized interconnection systems, TE Connectivity offers headers, in multiple configurations, and also supports flat / printed cables for highly compact board-to-board and board-to-device connections within battery management system applications.

MQS, NanoMQS and MCON are trademarks.