Building a Winning Race Car

Achieving success in motorsport begins with choosing the right components. By: Paul Webb

The Critical Components

From the outside looking in, you may think motor racing is nothing more complicated than flashy cars being driven round in circles on a Sunday afternoon to the delight of the devoted. It is however much more than that. Racing vehicles are pushed to the limit, far more than that of the average road-car. A lot more has to be completed behind-the-scenes to accomplish that kind of speed and durability. Yes, anyone can build a fast car. The trick in racing of course is to build a winning car. That is where things become much more complicated.

So what do we need to know about building a winning race car? Well, it is a combination of factors. If we take a look at the top teams in the world at the moment we find that they do not arrive there by chance. Not only that, but it is often a cyclical situation where they may be on top for a few seasons, but the opposition inevitably catches up and begins their own era of dominance.

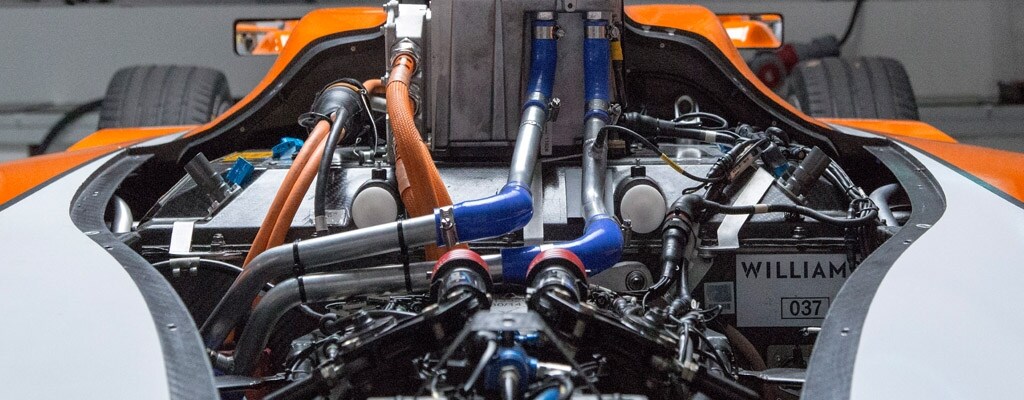

Let us begin with Formula 1. Mercedes and Lewis Hamilton appear to be able to do no wrong at the moment. However, the seeds of this success started way back in 2011 when the new engine regulations were agreed. Mercedes started work earlier than the opposition so they could understand the integration between chassis and powertrain. Here is our first lesson – get all the bits on the vehicle working together. Having an ace chassis makes little difference if the engine is below performance. All this really boils down to attention to detail. The slowest cars in Formula 1 are actually only round 6% slower than the front-runners, so the difference in first and last place really are not as dramatic as it may seem. It is the smallest details that make the difference. Indeed if just a small component is incorrect in the setup, the opposition will be there to gain the advantage.

Design and Sensors

The design of the car actually has to apply the laws of physics. Build a car to the minimum weight limit, as there is no point in using power to shift unrequired mass. Then, package it up to the requirements of the aero designers. This however is never an easy compromise. Here we come to another point. Every aspect on a race car is a compromise, either because the laws of physics says so or because another aspect of the car has to be taken into consideration. That driver's arms and legs actually make a successful aero package more challenging. There are numerous factors involved.

Where does TE come into this array of processes and details? As a major supplier of electrical products almost everywhere, we play quite the role. Long gone are the days in which the electrical components of the car were an afterthought. Cars and bikes are far more complicated now, with sensors controlling the actual running and dramatically increased performance capabilities.

As everything on the car is monitored, there is a need for a lot of sensing and connecting to gather this valuable data. Running a car is extremely expensive, so no tiny bit of data can be corrupt or unavailable whenever the car is alive. The optimum choice for this is the Deutsch Autosport and Raychem range of products. If there is movement, pressure or temperature to be analyzed, TE products are prepared to take on that challenge. However, if every car has access to our products, how does a team gain an advantage over the competition? How does someone have the winning race car? Over the years we have been able to offer custom options for those complicated interconnection solutions. This is due to our unique setup where we have the abilitiy to design, build, stock, and distribute from our Hastings factory.

The Role of TE

Due to providing custom solutions, we have to gather extensive technical details from the customer. This unique information about individual teams needs to be handled with extreme caution and we guard their confidences with much effort. They must not only trust the quality of our products, but also our integrity in the competitive world of racing.

Teams often ask us to reduce weight and help with super-tight packaging. Over the years our sensor connectors have gone from a military size 8 to a tiny Autosport designed size 2 (ASX). We are using the huge capabilities of TE to allow the teams to work on their own insert designs to allow a mix of higher and lower current harness designs. We continue to learn more about the components of a winning race car with every passing day. We went from inventing the way cars were wired up 20 years ago to now arriving on the cusp of offering solutions that would only appear in science fiction to our teams now.

Technology and new materials open up a whole realm of possibilities, and the strong relationships that we have forged in the racing industry allow us to play a key role in racecar design for many years to come. We continue to move into the future of racing with our cutting-edge products and long history of innovation.