Trend Insight

Rugged and Reliable: MIL-SPEC Micro-D Connectors

For high-stakes military applications where failure is not an option, MICRODOT (Micro-D) connectors deliver durability and dependability in extreme environments.

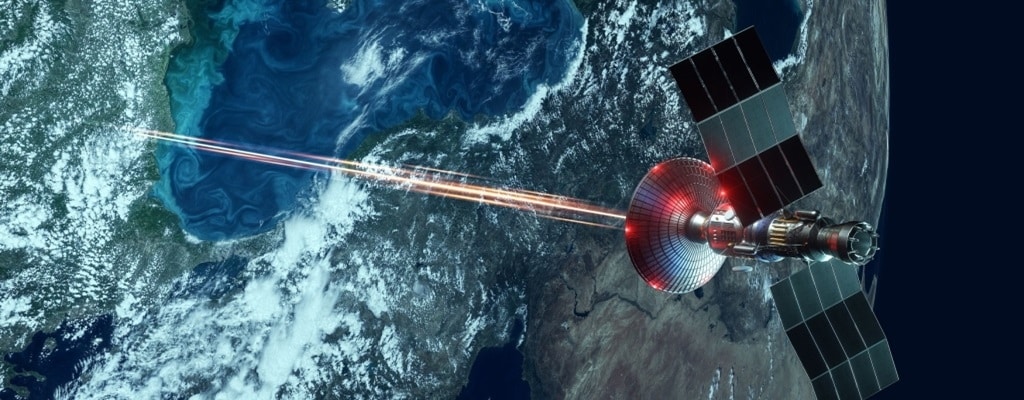

For high-stakes military applications where failure is not an option, MICRODOT Micro-D connectors deliver durability and dependability in extreme environments. In the harsh environments of today’s defense applications, reliability and performance are non-negotiable. Whether deployed in satellite systems, missile guidance, or military avionics, every component must be built to do its job, no matter the conditions. TE Connectivity’s MICRODOT connectors have demonstrated they are an essential part of these critical systems, offering extensive durability and reliability in the face of extreme conditions.

Designed for Rugged Environments in Military and Defense

Micro-D connectors are engineered for reliability in harsh and rugged environments, making them ideal for use in defense systems that require long-term durability. These military-grade connectors are time-tested in high-stakes applications such as:

• Missile guidance systems: Micro-D connectors deliver reliable communication between components, even as the system is propelled at high speeds and subject to rapid temperature changes.

• Satellite systems: Micro-D connectors must perform flawlessly at high altitudes, where radiation and extreme temperatures present unique challenges.

• Unmanned aerial vehicles (UAVs): Lightweight Micro-D connectors provide the necessary connectivity without adding much heft to the overall system, which is crucial for maximizing payload capacity and extending the operational range of the UAV.

Compliance to Military Standards: MIL-DTL-83513 and QPL

The reliability of TE’s MICRODOT connector portfolio is rooted in its compliance with the MIL-DTL-83513 standard for military-grade connectors. This military specification sets rigorous performance, durability, and reliability requirements for defense applications. The MIL-DTL-83513 standard governs various factors from temperature range and vibration resistance to contact resistance and dielectric withstanding voltage to mating cycles and corrosion resistance, supporting the connectors’ capability of withstanding high-performance demands in the field.

As a MIL-SPEC electrical connector, Micro-D components undergo rigorous testing and qualification processes to solidify their place on the Qualified Products List (QPL), a certification that is crucial for defense contractors. Products on the QPL, including Micro-D connectors, must be retested and requalified every three years, showing that they consistently meet the high standards required by military applications. This stringent quality control process provides defense customers with the confidence that they are selecting a reliable product for their mission-critical systems.

Compact Micro-D Design with High Performance

As defense technology evolves to pack more power into more compact spaces, the demand for smaller, lighter, and more powerful components continues to grow. Micro-D connectors are specifically designed to address space and weight constraints, providing high-density, high-performance solutions that meet military specifications.

In fact, as the need for miniaturization grows, implementation of Micro-D connectors is outpacing the use of legacy D-sub connectors. While both D-shaped connector options uphold performance standards, the Micro-D has the advantage of a smaller footprint.

Download MICRODT Micro-D Product Sheet

Gain the Edge through Collaboration and Innovation

In addition to the quality of its MICRODOT connector products, TE’s commitment to collaboration and innovation also helps its customers stand out in the defense market.

TE’s Micro-D connectors are highly customizable, allowing defense contractors to tailor the connector to their specific needs. Whether it’s a unique cable assembly or an integrated backshell design that reduces component count and weight, TE partners closely with its customers to deliver solutions that meet the exacting requirements of modern defense applications.

Through market sensing and continuous innovation, TE’s product portfolio is always evolving. In response to customer demand, TE has expanded its Micro-D product line , introducing connectors with new position sizes, such as the 69-position connector, which bridges the gap between the 51- and 100-position options. TE has also launched an integrated backshell Micro-D connector, which helps reduces the overall footprint and weight of the connector assembly.

Looking Ahead to the Future of Micro-D Connectors

As technology continues to advance, TE is already looking ahead to the next generation of Micro-D connectors. The need for even smaller and more powerful ultra-compact systems is growing. TE’s NANONICS line of D-shaped connecters offers nano-sized versions of the Micro-D connector and is poised to meet this demand.

Additionally, TE is exploring the integration of high-speed data capabilities, such as radio frequency (RF) and fiber optics, into the Micro-D form factor. This development could enable more advanced communication systems in defense applications, further enhancing the performance of military-grade systems.

As the defense industry continues to evolve, TE remains dedicated to innovation. Each development of the MICRODOT connectors aims to combine reliability, durability, and performance to meet the needs of future military missile systems, satellite avionics, and UAV technologies.

Key Takeaways

• TE Connectivity’s MICRODOT connectors provide exceptional durability and reliability for harsh defense environments, including missile guidance systems, satellites, and UAVs.

• These connectors comply with the MIL-DTL-83513 standard and are on the Qualified Products List (QPL).

• Micro-D connectors offer a compact design with high performance, addressing the growing demand for miniaturization in defense technology.

• A commitment to customization and innovation allows customers to tailor Micro-D connectors to their specific needs and benefit from TE’s evolving product portfolio.

• TE is developing next-gen Micro-D connectors, including nano-sized versions and potential integration of high-speed data capabilities.

Contact TE Connectivity to Collaborate on Your Next Defense Systems Design