POC and Device Microfluidics: Small Technology with a Big Impact

At some point, many point-of-care device developers find themselves asking a similar question: How do I ensure all the features needed for my device fit into this very limited space?

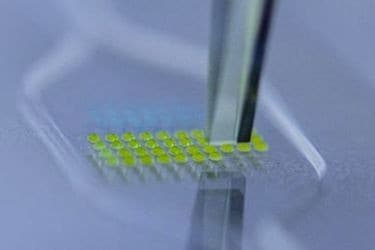

Oftentimes, microfluidics present the solution. “Microfluidics” refers to the practice of fluid manipulation through channels with very small dimensions. In point-of-care tests, small plastic devices are often the vehicle for a system of adding samples, storing and mixing reagents, incubating reactions, performing separations, adding substrates or trigger reagents, and providing the means to collect a signal. Because the device is often single-use and disposable, it doesn’t make sense to incorporate expensive technology into the design. Therefore, microfluidics present the most sensible and effective solution.

Microfluidic channels have dimensions that are sometimes small enough to be measured in the hundreds of microns. That scale changes everything. Fluids flow very differently at this scale than they do through, for instance, a garden hose. Laminar flow effects are present in the garden hose, but they are negligible. This is not so at the sub-millimeter scale. Fluids close to the walls flow more slowly than those in the center of the channels, and mixing becomes complicated. Using air pressure or vacuum to move the fluids around means that the channels must have very few openings, limiting options for the addition of other reagents.

Optical path lengths are also very small, so chemiluminescence looks attractive as a signal option. However, triggering the light can be complicated. Because microfluidics technology works in such small, precise dimensions, many companies lack the expertise to effectively incorporate it into their IVD devices.

Working With Experts to Incorporate Microfluidics

Even some organizations with years of experience in conventional assay development, manufacturing, and marketing will find themselves in unfamiliar territory when venturing into microfluidics. There may be an experienced team in place that knows how to develop and market the current product line. However, the world of microfluidics poses new challenges that even experienced teams may not have encountered before. It may rise to the challenge and devise solutions to fit the new challenges—but are the solutions the optimal ones?

Most companies seeking to incorporate microfluidics in their point-of-care devices work with specialists with demonstrated experience in the following areas:

- Assay development, including reagent storage and introduction

- Sample processing and introduction

- Immobilization of capture molecules like antibodies, complementary

- DNA, and enzymes

- Separation

- Washing and signal generation

It’s also beneficial to work with firms that have in-house experience in injection-molding microfluidic features with structural assemblies that achieve fluidic seals (thereby ensuring critical reagents remain stable while ensuring the requisite assay performance and detection parameters are achievable). This can reduce the number of potential product issues and shorten project timelines.

In short, companies that work with experts to incorporate microfluidics can expand their understanding of potential risks and innovative solutions.

Know our expertise in microfluidic development

Microfluidics Development Assistance

The considerations outlined above do not only apply to established organizations. From start-up to blue chip companies, the challenges posed by incorporating a precision technology like microfluidics can be challenging. For these companies, it’s critical to find the right partner with the appropriate expertise that can ensure they are utilizing microfluidics in their point-of-care devices efficiently and effectively.

To begin with, developing an understanding of the people that will use your product—and, importantly, how they will use it—is critical to the product’s conception and development. However, it’s surprisingly easy to lose sight of the user in the face of impersonal specifications and ambitious timelines. Enter usability testing: you can use it to anticipate problems with your point-of-care diagnostic or medical device before they even occur, and guide decisions on user interfaces and instructions for use (IFU). This way, you can ensure the product is being used in the way it was intended, and safely. This process is also critical if your product requires FDA approval.

Of course, there is the matter of manufacturing scaleup. It is one thing to make dozens (or even hundreds) of consumable devices and tens of assay processors/readers. It is another thing to reliably produce these in much larger quantities—ostensibly the goal of any startup—and do so profitably. In any manufacturing environment, increased volume is the key to decreasing costs. Cost savings are often realized by automating some portion of the process to reduce costly labor, but that can only be done when the process is totally debugged and well understood. Automating a process that must be abandoned because of a process change is wasteful and can be financially damaging. We can provide perspective in the scale-up process and help prevent costly mistakes in timing and product design.

Conclusion

For companies of any size, the solution for the effective incorporation of microfluidics and the subsequent success of a point-of-care product is to bring an experienced partner into the picture early. We develop and manufacture life science and diagnostic products, many of which incorporate microfluidic technologies. We help clients quickly turn their technologies into user-friendly, cost-effective, and clinically validated commercial products. Our in-house usability testing group and clinical research organization ensure that your product is optimized for the benefit of the end-user, your organization, and regulatory stakeholders.