The Impacts of Different Resins on Reagents

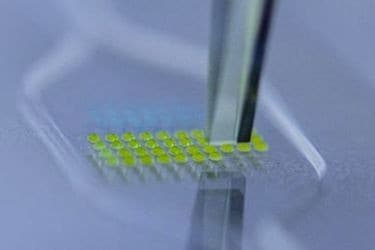

Microfluidic systems require careful consideration when it comes to chemical, thermal, and physical interactions with reagents. Interactions between the reagent and resin (or plastic/polymer) need to be minimized as much as possible to avoid leaching, system degradation, absorption, and unreliable assay outcomes.

Leaching thermoplastics or absorbing reagents can quickly create significant and unforeseen vulnerabilities within the system, not to mention adverse surface energy effects. Therefore, if a microfluidic system requires a specific set of chemical and thermal requirements, the plastic polymer selection process should consider polymers with appropriate chemical properties (or otherwise employ a custom polymer blend).

Any surface treatments or modifications should also be considered when selecting a resin. The need for specific levels of surface energy may require remedies if unexpected reagent additives, such as detergents, create adverse effects to the surface wetting ability of the resin.

These areas are often overlooked during the initial design process. In consequence, they often lead to problems at later testing and development stages. To avoid costly redesigns, carefully consider the following properties.

Plastics and Resistance Tables

Resins (or plastics) bring major benefits to microfluidic device development. They are cost-effective, reproducible, extremely adaptable, and ideal for disposable point-of-care devices. They can be molded far easier than inorganic and paper materials.Benefits aside, it’s important to consider device requirements and intended use before selecting a material, especially in the case of plastics. Plastic polymers are generally categorized into two forms: polydimethylsiloxane (PDMS) and thermoplastics.

PDMS is one of the most-used polymers due to its elasticity, biocompatibility, optical clarity, and gas permittivity. The material can be deformed under the application of force or air pressure, thus creating valves for greater fluid transport control. The disadvantages of PDMS can include unexpected channel deformation, low solvent and acid/base resistivity, evaporation, sample absorption, leaching, and hydrophobic recovery.

Alternatively, thermoplastics are rigid and benefit from mechanical stability, low water absorption, and, in general, solvent and acid/base resistivity. However, they vary in composition and reaction to certain chemicals. Thermoplastic families include polyethylene (PE), polycarbonates (Ac), polypropylenes (PP), acrylics such as polymethylmethacrylate (PMMA), cyclic olefin copolymer (COC), polystyrene (PS), and thermoplastic elastomer (TPE).

There are several noteworthy chemicals that can create significantly adverse effects among many polymer compositions, such as xylene, concentrated sulfuric acid, trichlorethylene, and chloroform. Such chemicals have been reported to have major deteriorating effects on most polymer groups (though there are some exceptions). Manufacturers often report polymer group chemical compatibility and resistances in tables that describe information about water absorption, solvent and acid/base resistance, optical transmissivity, and thermal properties. In fact, hundreds of such tables exist. The information in these tables is important to understanding the interaction between a resin and an intended reagent. These tables should be carefully reviewed to ensure that the device is stable and that the intended assay is accurately performed. An adequate resistance to acids, bases, and solvents is vital for any polymer-based microfluidic device as exposure may lead to the deterioration of microchannels.

Be aware that while these tables may provide a “big picture,” they don’t necessarily provide the “whole picture.” Many of them concern a specific company’s products and focus on physical integrity (sadly, there are no truly comprehensive resistance tables due to the wealth of brands and products on the market). In addition, they typically do not adhere to a single rating standard. Some tables for specific polymers do exist, but that information is not found elsewhere.

(It’s important to note that while resistance tables tend to generalize polymer groups, thereare custom polymer companies whose business model is based on formulating the best polymerfor your specific requirements.)

Proven Expertise, From Concept to Market

Absorption and Leachables

Absorption and leachability are often not considered until late in the IVD device design process. This could be a mistake: early consideration of these properties can ensure that their impact on reliability and outcome is minimized.

Leachables are chemicals that leak into the product from the system that contains it (in this case, the polymer structure) under normal product, application, or storage conditions. Conversely, absorption refers to the product leaking into or adhering to the surrounding polymer structure. To compound matters, absorbed compounds trapped in the polymer can degrade the structure and then leach into subsequent assay samples. Thus, the inclusion of unforeseen compounds in the product can create a significant issue for the reliability, efficacy, and safety of the assay.

In IVD device design, a resin’s potential for leachability and absorption needs to be thoroughly considered to minimize adverse effects. The pH level of the reagent may have a significant impact on the release of leachable compounds. Such compounds may be acidic or basic; thus, the reagent itself may provide a method of extraction for the leachable compound, as the solubility and accumulation level will be pH dependent. In addition, extraneous conditions such as strong solvents, high temperatures, and long durations may lead the leachable compounds to be solubilized to a higher degree. The presence of salts and detergents may also present an increase in the levels of solubilized leachables in the product.

It is essential to ensure that any polymer selected minimizes the potential for leachables and absorption so that assay performance is not impacted. This can be carried out with a side-by-side assay comparison with similarly sized molded polymers featuring comparable surface-area-to-volume ratios.

Surface Energy and Modifications

Fluidic control depends greatly on surface energy and specific reagent formulation. Surface energy is formed from the high surface-area-to-volume ratio that occurs within fluidic systems at the microscale. Subsequently, surface energy varies widely throughout the microfluidic system—from hydrophobic/oleophobic (low surface energy) to hydrophilic/oleophilic (high surface energy)—depending on the materials used.

Surface energy is driven by “surface wettability,” or the degree to which a liquid spreads across the surface of the material interface. Surface wettability arises from the intermolecular forces acting between the molecules of the reagent and material surfaces.

Surface energy is measured by observing the contact angle formed between a water droplet and the material surface. These forces are the product of the properties of the reagent chemical and the surface (or coating) hydrophilicity. Thus, by providing additives to the water, surface tension forces can be adjusted. For example, salts have a relatively small impact on surface tension. On the other hand, detergents and benzene derivatives have a larger impact.

Polymers have natural surface energy properties; however, it is possible to customize or chemically modify the polymer to affect it. Surfaces can also be treated to adjust the surface energy through priming (or chemical coatings), plasma cleaning, vapor deposition, and adjustment of the surface texture and polish. The texture and polish can influence the surface energy, whereby a more polished surface is generally more hydrophobic. The resolution of the surface texture depends on the resin “flow” and the molding parameters such as temperature, injection pressure and speed, and cycle time.

Conclusion

Resins offer cost-effective solutions for microfluidic systems; however, costly redesigns can diminish this benefit. The interaction between resins and reagents can have significant impacts on the efficacy of the microfluidic device and the intended assay. It is essential to consider every resin/reagent interaction to build a complete picture of the viability of a potential resin-based solution.