Extruded Tubing

Medical grade extruded tubing is an essential component that upholds the integrity and safety of medical devices. TE supplies high-efficiency single-lumen, multi-lumen, bump, monofilament, tapered, beaded, and profiled extruded tubing to medical device manufacturers who want to offer advanced functionality within the size constraints of their coronary, peripheral, and neurovascular devices.

Our tubing provides exceptional biocompatibility in a variety of custom sizes and configurations, across a spectrum of temperature sensitivities, for highly precise pairing of form with function. We keep a comprehensive inventory of precision-engineered extruded tubing in climate-controlled conditions for quick deployment to your device manufacturing needs.

Performance Considerations

Medical grade extruded tubing is an essential component that upholds the integrity and safety of medical devices. Specialized design and manufacturing ensure that medical professionals can rely on these tubes for accurate diagnoses, effective treatments, and improved patient outcomes. In order to ensure patient safety in all applications, it’s important to consider the functional aspects of extruded tubing, including:

- Flexibility and stiffness: Finding the right balance between flexibility and stiffness depends on the specific medical application and intended use of the device. Extruded tubing must be flexible enough to offer patient comfort and ease of navigation, but also stiff enough to offer device stability and shape retention.

- Pushability: Stiffer tubing provides better pushability and control, which is essential for devices used in procedures like angioplasty or stent placement. When tubing needs to be maneuvered precisely within the body's vessels, stiffness facilitates this control.

- Kink resistance: Kinking can impede the functionality of medical devices and potentially cause complications. Flexible tubing is less prone to kinking or folding, ensuring a continuous and unobstructed flow of fluids or gasses.

- Lubricity: A lubricious surface reduces friction between the tubing and bodily tissues, making it easier to navigate through the body's pathways. Lubricity plays a significant role in the ease of insertion for medical devices that incorporate extruded tubing, such as catheters, guidewires, or endoscopes. This minimizes discomfort for the patient and lowers the risk of tissue damage or irritation during insertion or removal.

- Ability to laminate and reflow: By combining different materials in layers, laminated or reflowed tubing can achieve a balance of properties, such as barrier protection, flexibility, and structural integrity, that wouldn't be possible with a single material.

Materials & Specifications

Medical OEMs who partner with TE can choose from a spectrum of medical-grade extruded tubing options, as well as custom types and blends for specific performance requirements. Putting the exact extruded tubing product in your hands on your schedule requires operational efficiencies and technical expertise, such as:

Inventory

Robust inventory of shapes and types

Our standard extruded tubing configurations include single-lumen, multi-lumen, bump, monofilament, tapered, beaded, and profiled. We can also design and manufacture custom configurations for your specific medical device requirements.

| Type | Capabilities |

|---|---|

| Single Lumen |

|

| Multi Lumen |

|

| Bump |

|

| Monofilament |

|

| Profile |

|

Materials

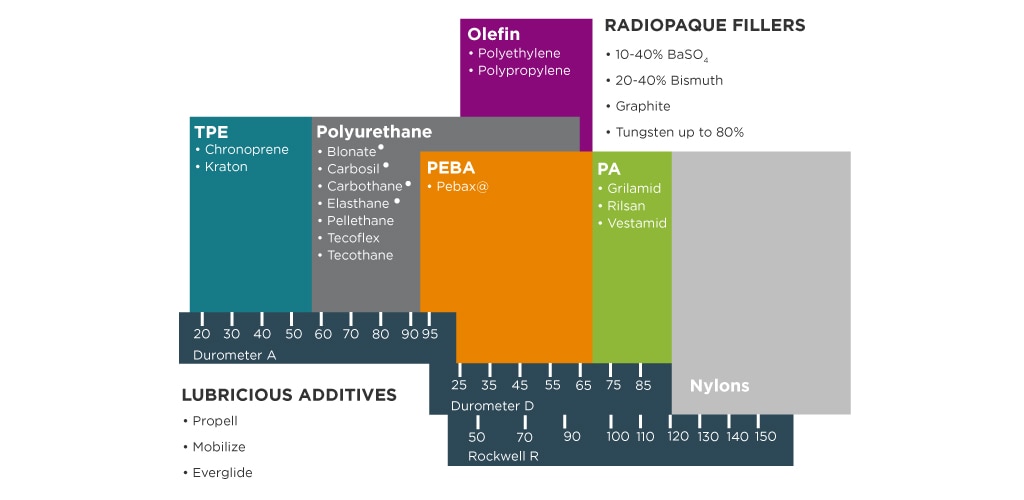

Wide variety of primary materials

Precision applications require intentional selection of specific component materials in order to support optimal device performance. Choose from our biocompatible thermoplastic polymers and fluoropolymers to meet your specialized requirements for lubricity, temperature sensitivity, rigidity, friction, and insulation.

Additives

Durable additives for enhanced functionality

In medical devices, there is often a delicate balance between flexibility and ease of glide. The extruded tubing used in each device will need to have specific properties to respond to the particular environment of use. TE offers extruded tubing with a wide variety of lubricious additives such as Propell, Mobilize, and Everglide so you can fine-tune the flex and friction your device needs for optimal performance.

Supply

Protected supply chain

The precision required to build medical devices rarely has latitude for materials substitution during manufacturing, assembly, and testing. That’s why TE has built up a deep and durable, internal supply chain with over 350 resins in stock and stored in a climate-controlled environment. We can create your components quickly and efficiently from our wide array of precision materials on hand. Whether you’re looking to create catheters, stents, or other devices with precision tubing requirements, TE has a robust matrix of materials to meet your needs or start the conversation about customizations for your specific application.

Technical Resources

Manufacturing Locations

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e