-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

- Bulk Order Purchasing

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Overview

This product is not currently available. For more information, including distributor inventory, please contact us.

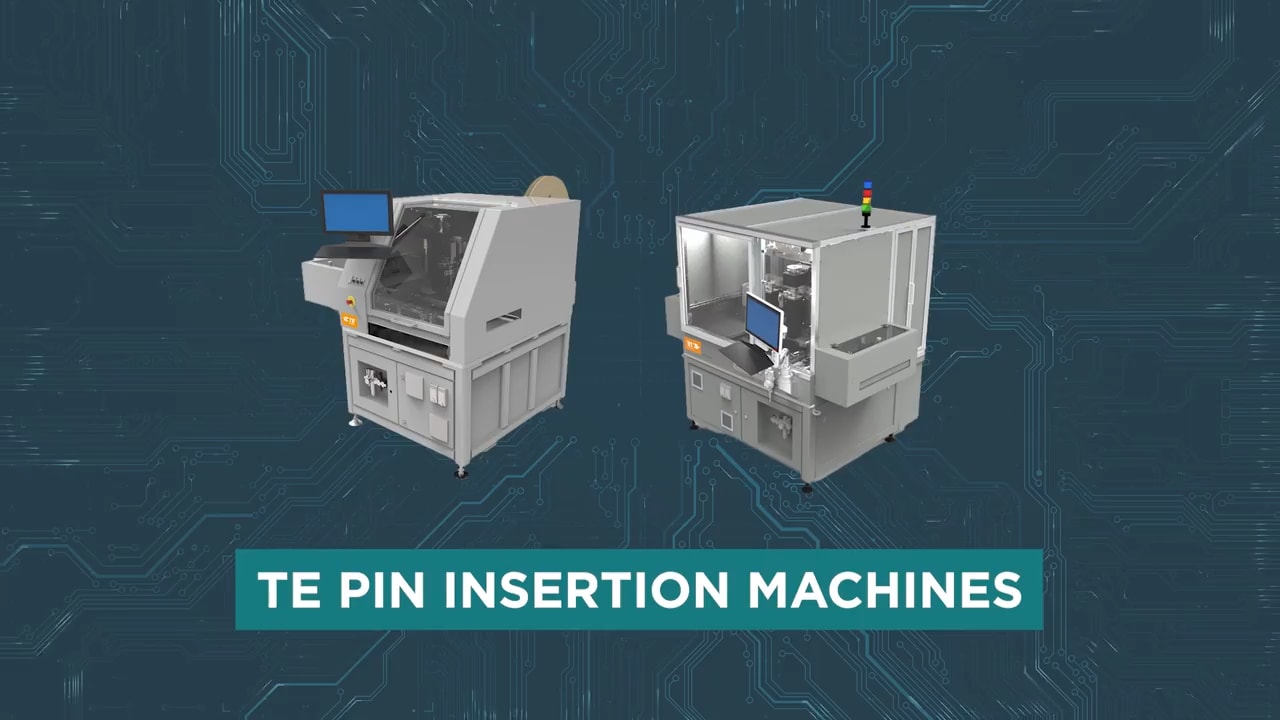

P280 PIN INSERTION MACHINE

Available from

Build and price the product now

2.8

Maximum Insertions Per Second

2

Up to 2 Insertion Heads

900N

Maximum Insertion Force (More is possible on request)

Features

For Your Current and Future Tooling Needs

- Board capacity up to 420 x 360mm [16.5" x 14.2”]

- Up to two insertion heads

- Tool conversion kit changeover in less than 10 minutes (compatible with

P100/P300/P280/P360/P550) - Freely programmable 360° insertion angle (rotation of up to +/- 90-degrees has no influence on insertion rate)

- Insertion rate up to 2.8 cycles/second (up to 3 contacts per stroke)

- Single, double and triple pin insertion

- Active lower anvil provides support to the PCB during insertion and offers special actions such as clinching (when applicable)

- Maximum insertion force 900N (more is possible on request)

- Lower support tool equipped with pin presence check support

- Real-time force monitoring for quality control (maximum force and force vs. distance monitoring)

- Vision system for PCB alignment accuracy

- Servo motors for XY

- Fully automated, inline capable, uni-directional or bi-directional PCB transport

- Up to two different contacts on one tool position with twin feed tool

- Touch screen provides simple programming and an intuitive operator interface

- Able to process any manufacturer's reeled contacts (including Nano contacts)

- Contact bending feature allows for the bending of contacts up to 90-degrees

- PCB thickness tolerance compensation

- Industry 4.0 ready with modularization options

- Customized MES connection

- Full traceability capabilities

- Universal PCB clamping

- Automatic PCB width adjustment

- Reel change without interrupting production

- Bulk processing

- Connector stitching capable into any non-PCB product

- Accommodates a wide range of male and female contacts

Learn more about our Pin Insertion Machines, which are engineered to apply products from TE and other manufacturers to meet your diverse production requirements.

TE Connectivity

TE PIN INSERTION MACHINE LINEUP

Offering a Wide Range of Production Equipment for Compliant Pin Technology

Pin Insertion Lineup

- Highly Customizable to Meet Your Production Requirements

- Simple Programming

- Force Monitoring for Control and Quality

P10 Single Pin Repair Station

- For repair and low volumes

- Manual press with ratchet mechanism

- Application of a single pin, manually loaded into the insertion finger

Products that can be processed:

ACTION pin contacts

AMPMODU contacts

Cross contacts

EON board to board

EON board to housing

FEC pins

GDS contacts

Junior timer

Junior power timer

MQS pins

PCB contacts

PCB coupler

Solder tabs

Spring contacts

Tabs

P100 Pin Insertion Machine

- Manual PCB loading

- Designed for mid-volume level production up to 5 million contacts per shift and year

- Can accommodate up to 2 insertion heads

Products that can be processed:

Press-fit contacts

Solder contacts

Pins & tabs

Sockets

Spring contacts

Continuous wire

F-post

- Insertion force:

900N (max)

- PCB size:

420 x 360mm (max)

30 x30mm (min)

- Insertion area:

300 x 310mm

- Insertion speed of pin:

150mm/sec (max)

P300 Pin Insertion Machine

- Flexible and fully automatic

- Designed for mid and high-volume level production up to 15 million insertions per shift and year

- Available as either stand alone or integrated into a production line

Products that can be processed:

Press-fit contacts

Solder contacts

Pins & tabs

Sockets

Spring contacts

Continuous wire

F-post

- Insertion force: 900N (max)

- PCB size:

420 x 360mm (max)

80 x80mm (min)

- Insertion area: 410 x 340mm (w/o flip unit) 340 x 220 (w/ flip unit)

- Insertion speed of pin: 300mm/sec (max)

P360 Pin Insertion Machine

- Modular high speed insertion machine

- Designed for high-volume level production up to 25 million insertions per shift and year

- Available as either stand alone or integrated into a production line

Products that can be processed:

Press-fit contacts

Solder contacts

Pins & tabs

Sockets

Spring contacts

Continuous wire

F-post

Multiple Line Configurations Available

- Stand alone

- Extension of 3 or 4-head machine

- Modular Line

- Servo driven base insertion head

- Single insertion head (up to 2 different contacts with twin feed)

- Freely programmable insertion angle (rotation has no influence on insertion range)

- Lower support tool equipped with pin presence check

- Clinching in lower tooling is possible

- Insertion speed of pin: 500mm/sec (max)

P550 Pin Insertion Machine

Products that can be processed:

Press-fit contacts

Solder contacts

Pins & tabs

Sockets

Spring contacts

Continuous wire

F-post

- Insertion force: 900N (max)

- PCB size:

420 x 360mm (max)

80 x 80mm (min)

- Insertion area:

410 x 340mm

- Insertion speed of pin:

500mm/sec (max)

- Flexible and fully automatic high-speed operation

- Designed for high levels of production volume

- Freely programmable insertion angle (rotation has no influence on insertion range)

Optional Features on Select Models

- PCB flip unit

- Available on the P300, P360 and P550 Models

More options are available. For a complete list please contact your local TE representative.

- Same side in and out PCB carrier handling

- Available on the P300, P360 and P550 Machines

- Single, double and triple pin insertion

- Available on P300, P360 and P550 models

TE PIN INSERTION MACHINE LINEUP

Applications

- Printed circuit boards (PCBs)

- Connectors and housings

- Insulated gate bipolar transistors (IGBTs)

- Flat flexible cable (FFC)

- Flexible printed circuit (FPC)

Products Processed

- Press-fit contacts

- Solder contacts

- Pins and tabs

- Sockets

- Spring contacts

- Continuous wire

- F-Post

- Loose piece components on request

Related Pin Insertion Machines

TE P Series

-

P550 Pin Insertion Machine

Engineered for high-volume PC board processing, our P550 Pin Insertion machine offers multi-head, high-speed performance at 5+ strokes/second on a 30mm pitch.

-

P360 Pin Insertion Machine

Our modular, high-speed P360 Pin Insertion Machine is engineered for high volume production and suited for a wide variety of line configurations.

-

P300 Pin Insertion Machine

The P300 automatic machine processes reeled press-fit and thru-hole components. As a stand-alone unit, or in an SMEMA compatible production line, it increases throughput by lowering cycle times and scrap.

-

P100 Pin Insertion Machine

Our semi-automatic P100 Machine was designed with a focus on mid-volume production and provides a broad range of features, including a touch-screen for simple programming and automatic setup.

-

P10 Single Pin Insertion Station

Suited for repair of very low volumes and designed for convenience and ease of operation.

Please review product documents or contact us for the latest agency approval information.

Other

-

Maximum Unique Products 2

-

Maximum Contacts (seconds) 2.8

Reference Number

-

TE Internal Number CAT-P280

Datasheets & Catalog Pages

- TE Pin Insertion Machines pdf English

Instruction Sheets

Instruction Sheet (U.S.)

- PIN INSERTION MACHINES DOCUMENTATION REQUEST pdf English

Are you sure you want to close chat?

To begin your chat with TE please enter your details