Maximize Your Production Efficiency

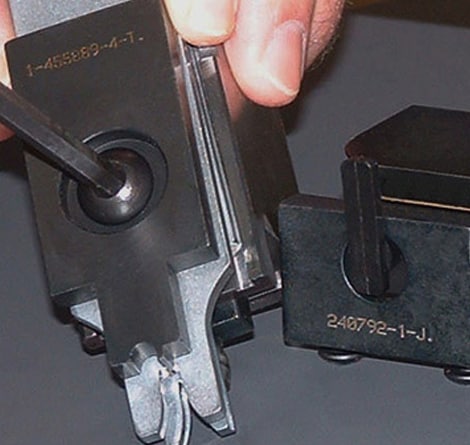

Our AMP-O-LECTRIC Model G Terminator with Thru-Splice Applicator is designed to apply thru-splices and provides access to both sides of the applicator for placing and holding the wires. The splice terminator is offered in two versions, with and without Crimp Quality Monitoring (CQMII). Equipped with the optional CQM II, force and position can be measured during every crimp cycle, providing real-time monitoring of crimp height—the fundamental crimp characteristic. The CQM II also monitors the shape of the work curve for every termination. Variations in the work curve may indicate improper wire placement, incorrect wire size, insulation in the wire barrel and tooling wear. The machine also features full guarding for operator safety. * Currently sold only in the Americas and Asia/Pacific.

Features

- Open access behind crimper maximizes production efficiency

- All the features of the proven Model G Terminating Machine

- Magnet-wire splice capability

- Crimp Quality Monitor II (CQM II) option

- Precision manual crimp-height adjustment

- Total and batch counter

- Low maintenance

Ordering Information

| Part Number | Description |

|---|---|

| 2217002-1 | Terminator with Manual Crimp Adjust |

| 2217002-2 | Terminator with Manual Crimp Adjust with CQM II |

| Various* -2 | Applicator (-2 CE version of applicator is required) |

*Dependent on terminal. Please contact your local TE representative for the proper applicator number or call the Tooling Assistance Center at 1-800-522-6752.