Quality Precision in Every Press

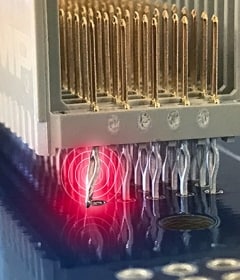

Our automatic press (AP) 3T/5T machines apply compliant pin connectors to a wide range of PCBs. They are fully capable of handling demanding applications such as daughter cards, mid-planes and backplanes in data communication, aerospace defense & marine, medical, automotive, and energy industries.

Features and Benefits

Optimized High-Performance Tool

- Windows 10 operating system closely monitors force, distance and speed

- Touch screen monitor for enhanced machine operation

- Two barcode scanner options:

- One vision camera for PCB offset can integrate barcode scanner function

- Customer can also add an extra scanner

- Five load cells for pressing force monitoring

- One low force range load cell dedicated for the low force monitoring, sensitive for detecting bent pins at the early stage of pressing cycle, reduces scrap and simplifies troubleshooting and maintenance

- Four high force range load cell to confirm high precision measurement

- We offer an integrated floating head that can adaptively enter the male- female connector, while a rigid head frequently faults alarms or can easily crush the connector

Quality and Control Management

- Automatic X/Y/Z axis and rotation press head motion control

- PCB capacity of the AP 3T/5T machine is 760 x 880 mm (30 x 36 in)

- The statistical process control (SPC) feature within the machine’s included software provides a press log and allows press force plotting for every connector

Customizable

- Manufacturing execution system (MES) available to meet your production requirements

- Wide range of insertion heads for TE & non TE terminals

Industries and Applications

- Data Communications

- Aerospace Defense & Marine

- Medical

- Automotive

- Energy

Applications

- Data Centers

- Servers

- Switching & Routing

- Storage

- Printed Circuit Board Assembly (PCBA) – Aerospace Defense & Marine

- Insulated-gate Bipolar Transistor (IGBT) – Automotive & Energy