Reliable and Efficient Heat Shrink Solutions

Our new semi-automatic RBK X1C heat shrink tubing processing machine is designed for sealing wire bundles, splices, and ring terminals and features long-lasting heating elements as well as operator key lock/password protection levels.

Reliable, efficient production. The RBK X1 processor is a semi-automatic unit designed specifically for sealing wire bundles, splice terminals and ring terminals. Suited for low volume/high mix production, the machine features long life heating elements, operator key lock/password protection levels and individual selections for installation times, temperature and product size information. It also offers a highly reliable PLC control, short machine depth to accommodate a larger front working area, low profile and sequence processing.

600°C

Maximum Operating Temperature

75mm

Maximum Tubing Length

19mm

Maximum Tubing Diameter

Features and Benefits

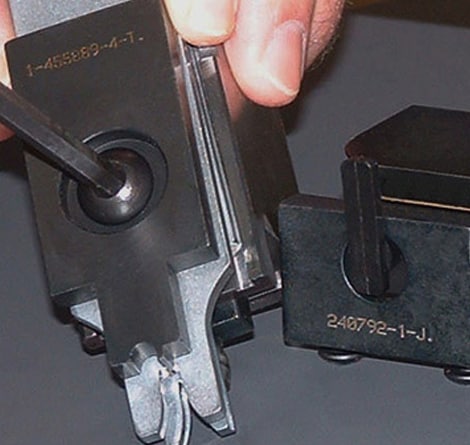

New High-Performance Tool

- Competitively priced alternative to less measurably reliable heat guns

- Automatic centering of tubing over the splice prior to heating

- Air-cooling after shrinking, and adjustable cooling time by ultrasonic welder

- Reliable PLC (Programmable Logic Controller) control with short machine depth to accommodate a larger front working area

Quality Process Control

- Stand-alone (Operator sets time & temp)

- Sequence (Preset times & temps can be sequenced automatically)

- Remote (Receiving data automatically from external device)

- Barcode (program is selected from a database by barcode reading)

One of a Kind

- Only machine of its kind in the market at the present time that allows cooling time programming from welder independently from other process parameters

Industries

- Industrial

- Appliances

- Automotive

- Aerospace Defense & Marine

- Performance Materials

Applications

- Welding Machines

- Heat Shrink label for cables

- Wire bundles

- Stub Splice and In-line Splice terminals

- Ring terminals

GET IN TOUCH WITH BÖRSIG

Demo our RBK-X1 Machine with our trusted Partner Börsig GmbH Electronic

For your convenience, we inform you that our authorized partner, Börsig GmbH Electronic not only holds inventory to support your current product needs but is also equipped to provide a live demonstration of the RBK machine. Their team is well-prepared to support both commercial and technical inquiries