Multiple Bussed Amplivar Splices Support Splicing of Four or More Magnet Wires

AMPLIVAR splices now support nearly infinite splicing in a multiple bussed configuration. New versions of AMPLIVAR Product Terminator (APT) machines allow their cutoff shears to be controlled. This permits three specific models of 9-serration, pigtail-type AMPLIVAR splices to be used in a serialized or bussed configuration. Each compression crimped splice will accommodate three copper or aluminum magnet wires. With the crimped splices bussed together they support nearly infinite splicing combinations.

Product Features

- Proven, existing AMPLIVAR splices can be used in multiple bussed configurations for nearly infinite splicing of magnet wire

- Machined serrations in splice crimp barrel pierce insulating film on magnet wire and create quality electrical connections that are mechanically strong

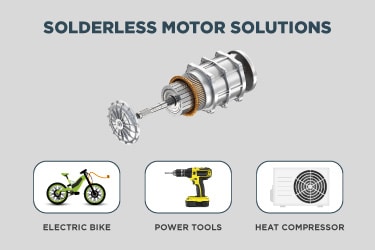

- No prestripping or soldering of magnet wire is required

- Accommodates both copper and aluminum magnet wire

- Compression crimp eliminates cold solder joints, weld burns and potential wire or component damage from thermal processes

- Bussed terminations can be created using new APT-5 machines or existing APT-5 machines when equipped with available retrofit kits