Power Busbar Solution

As data volume and broadband use continue to expand, Power capacity demands increase for data communication and telecommunication. TE innovated busbar solutions can help customers to offer exceptional performance and dependable power distribution systems with consistent quality, and excellent electrical characteristics.

What is Busbar and why use Busbar

- Be Made out of aluminum or copper

- Be used in electrical power distribution

- Transmit high current power from the source to the load

Busbar solution benefits

- Long lifespan and more stable, eliminate wiring errors

- Lower space requirements. Cables require more bending radiuses and parallel spacing.

- Better heat dissipation

- Ease and speed of installation as many connectors are hot pluggable in tapping points.

- Low cost: less complex system design and less labor cost due to easy installation

TE Power Busbar Advantages

- Complete Turn Key: Busbar, Connectors and Components full Integration

- Busbar Development: Design, simulation, testing & manufacturing

- Cost Competitive Solutions: Market competitive solutions meeting requirements

- Regional Capabilities: Design Teams and Supply Chain: Asia & North America

- Quick Response: Short lead time for both quotation and sample building

Smart Busbar

New Product

Power connectors inside of server racks may undergo temperature-related failures, causing service disruption. Outfitting power connectors and busbars with sensors enables real-time monitoring of their condition, allowing careful overdriving and planned repairs.

Key benefits:

- Smart busbar power connectors send temperature data to a server rack controller.

- Failures can be predicted and corrected.

- Connectors can operate with higher current when protected with monitoring.

- Output can be communicated wirelessly using RF signals or using thermistors.

- Powered from busbar, no additional power source.

Liquid Cooled Busbar

New Product

In partnership with customers, TE is enable the next-gen power busbar solutions empowering artificial intelligence evolution. As rack level power requirements continue to increase, busbar capacities need to follow suit. Using liquid cooled infrastructures to cool the power busbars enables higher current capacities, while maintaining lower temperatures.

Busbar Types

Rigid Busbar

Features & Advantages

- High current carrying

- More better floating

- Lower system noise

- Better for test and maintenence

Capabilities and value add

- Copper thickness: 1mm~20mm

- Forming: CNC/Laser cutting, Bending, punching, machining

- Isolation: Epoxy coating

- Plating: Tin, Nickel, Ag, Au

- Welding: Ultrasonic welding, Laser welding

- TE connector solutions

- Press riveting

- PEM insertion and attachment

Laminated Busbar

Features and Advantages

- Size Minimize

- Low Resistance, High Capacity

- Improved heat dissipation, lower T-rise of system

- Reduce the damage from voltage peak

- Reduce system noise and EMI

- Error proof installation

Capabilities & value add

- TE connector solutions

- Press riveting

- PEM insertion and attachment

- Multiple layers of conductor and insulation

- Varied insulation materials available

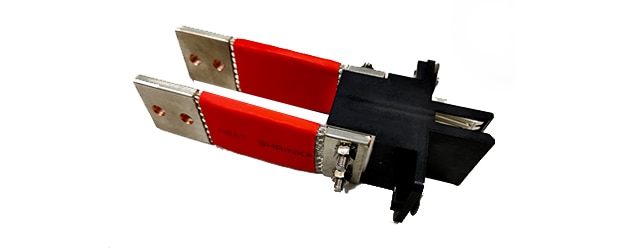

Flexible Busbar

Features & Advantages

- High current carrying

- Good flexibility, better floating

- Save space

- Easy to install

- Easy for test and maintenance

Capabilities and value add

- Round and Flat braided wire

- Insulated and uninsulated versions

- Multiple copper sheet stack version

- Felx/rigid combined solution with welding

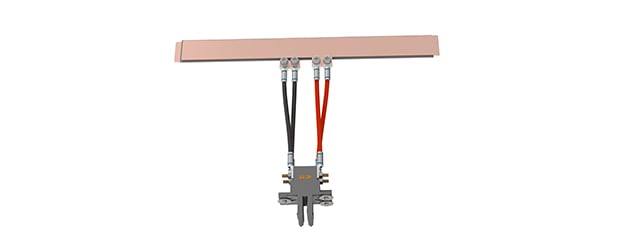

Cabled Busbar

Features & Advantages

- High current carrying

- More better floating

- Lower system noise

- Better for test and maintenance

e

e

e

e

e

e

e

e

e

e

e

e