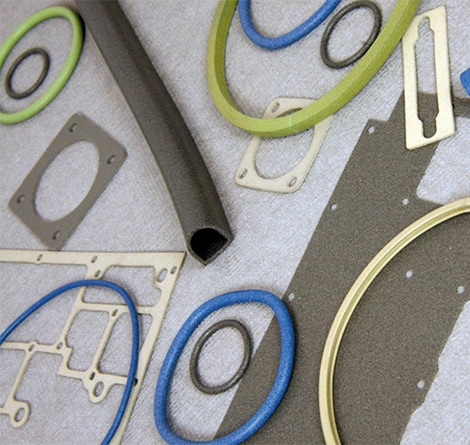

Form in Place Gasket

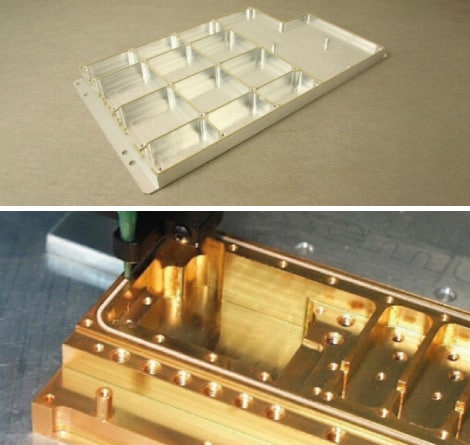

Electrically conductive or non-conductive silicone elastomer compounds are deposited as a gasket directly to the enclosure by XYZ CNC technology. These gaskets can be very intricate small sections suitable for enclosures with no space for a traditional gasket such as thin walled multi compartment housings providing an EMI and environmental seal.

Overview

Kemtron Form-in-Place FIP Gaskets are elastomer compounds directly dispensed onto component hardware or enclosure via a pressurized fluid dispensing system on a numerically controlled XYZ table to form a gasket for RFI/EMI shielding and/or environmental seal for dust and moisture. The dispensing machine deposits the gasket by following a pre-determined CNC path to provide accuracy and repeatability. We work with supplied free issue components.

Materials

- Nickel Coated Graphite in silicone.

- Silver Plated Aluminum in silicone.

- Silver Plated Copper in silicone.

- Silver plated Nickel in silicone.

- Non-conductive silicone.

Applications

Suited to applications where small, intricate EMI gasket profiles are required, such as on multi-compartment labyrinth housings with minimum gasket land area where traditional larger types of gaskets are not suitable. This process also negates the assembly costs associated with traditional gaskets as the Form-in-Place gasket becomes an integral part of the housing or enclosure. The process is suitable for depositing on both metal and metallized plastic components/housing.

Kemtron Ltd., now part of TE Connectivity Extended product portfolio

Contact information

United Kingdom

Phone: +44 (0) 1376 348115

Email : info.braintree@te.com

France

Phone: + 33 (0) 160778316

Email : info.braintree@te.com

Germany

Phone: +44 (0) 1376348115

Email: info.braintree@te.com

Rest of Europe

Phone: +44 (0) 1376348115

Email: info.braintree@te.com

Asia

Phone: +44 (0) 1376348115

Email : info.braintree@te.com