RTD Temperature Probes

Our RTD probes are designed to provide precise, stable measurement in various applications and industries including industrial controls, HVAC/R equipment, oil and gas, energy, and appliances.

Product Features:

Capabilities of TE's RTD Probe Portfolio

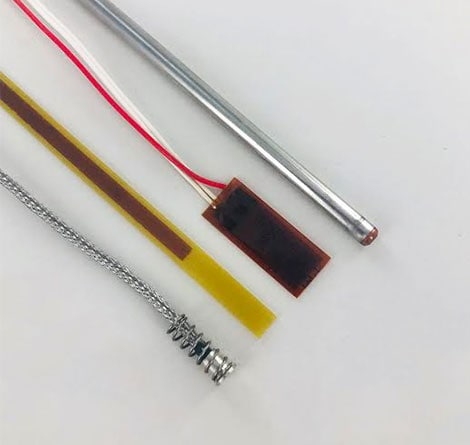

- Various sensor configurations including stator and bearing probes, point sensing probes, air sensing and averaging probes, and direct immersion probes

- Sensor packages with hazardous location approvals including intrinsically safe and explosion proof areas

- Materials include but are not limited to stainless steel, fiberglass, polyimide, ceramic, and specialty alloys

- RTD sensor elements include platinum, copper, and nickel materials

- Temperature limits up to 600°C

Frequently Asked Questions

Q: What is an RTD?

A: An RTD (Resistance Temperature Detector) is a sensor whose resistance changes as its temperature changes. The resistance increases as the temperature of the sensor increases. The resistance versus temperature relationship is well known and is repeatable over time.

An RTD is a passive device. It does not produce an output on its own. External electronic devices are used to measure the resistance of the sensor by passing a small electrical current through the sensor to generate a voltage.

Read More: Understanding RTDs

Q: Why are there different types of alpha curves for platinum RTD element?

A: Different agencies or organizations (i.e. governmental, industrial and trade) have defined curves in an effort to develop a standard by which all manufacturers can operate. Some were developed by individual manufacturers based on their own abilities to offer a reproducible curve.

Read More: RTDs & Thermocouples FAQs