Cartridge Contract Manufacturing

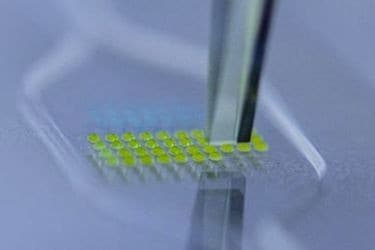

TE Connectivity offers high-precision, high-volume, cost-effective microfluidic contract manufacturing for IVD and Life Science companies.

Making the transition from pilot line to high-volume production isn’t as simple as dialing up the speed on a production line. This transition requires skill in microfluidics design, nano- and micro-fabrication, polymer science, automated assembly, and more. TE Connectivity is a pioneer in the Contract Manufaturing microfluidic business with +15 years of experience in microfluidic manufacturing practices to larger-volume targets and assists in the path to meeting market demand.

Manufacturing Competencies

- Design for Manufacturing and Assembly (DFMA)

- Microinjection Molding

- Surface Treatment

- Automated Reagent Deposition/Integration

- Bonding/welding Technologies (chemical, plasma, solvent, thermal, laser, ultrasonic...)

- High-Throughput Lamination Equipment (Adhesive and Thermal)

- Assembly Membrane Placement

- Leak Testing

- Heat Testing and Treatment Blister Forming, Filling, and Sealing

- Quality Assurance and AI Quality Control

- Clean Room AssemblyInstallation/Operational/Performance Qualification

- Gap Manufacturing

- ISO 13485 Certification

- Photolithography Technology (Class 10–100)

- Thin Film Processing

- Plasma Etching

- Bonding processes

Design for Manufacturing and Assembly (DFMA)

TE employs DFMA techniques to map the lifecycle progression between proof-of-concept prototypes and medium- to high-volume manufacturing from the project's earliest stage. Cost, throughput, and efficacy targets are identified to ensure that your IVD device is manufactured with a high degree of reproducibility and quality. To avoid increasingly expensive production obstacles later in the product lifecycle, our expert team consults with you to formulate a design risk matrix that encompasses prototyping, clinical research, and manufacturing requirements. TE’s ISO 13485-certified facilities allow for the production of accurate, reliable and cost-effective cartridges.

Remedies for Cartridge Manufacturing Gaps

Most manufacturers encounter phases whereby production needs are growing, but market demand does not yet warrant the shift to high-volume manufacturing. TE helps navigate this interim period to formulate the best path to large-scale production. TE's design transfer checklist manages key milestones in the transition from batch to moderate to large scale manufacturing.

Areas of Expertise

Material Compatibility for IVD Consumable Development

Understanding the complex array of interactions between resins and reagents in IVD consumable manufacturing requires specialized knowledge to ensure that the switch between materials at different production milestones is stable and effective, with no impact on performance. Because of our extensive experience with a wide range of polymers commonly used in diagnostic cartridges, we understand their limitations at various production volumes. This knowledge can help avoid issues in manufacturing, assembly, reliability, and functionality.