CARTRIDGE MATERIAL SELECTION

TE Connectivity's microfluidics experts reduce development risks with effective materials selection for cartridge design and manufacturing.

Selection of IVD Consumable

There are several factors that influence the selection of IVD and Life science microfluidic cartridge materials. These include cost, volume, biocompatibility, autofluorescence, reagent compatibility, and the microfluidic chip’s intended use.

With the expertise of an experienced microfluidic technical and manufacturing team, trust TE to provide guidance on microfluidics materials selection and assist in the scaling up of mass production for any application.

Core Microfluidic Competencies:

- Bioassay Transfer

- Microfluidic Device Design

- Feasibility Testing

- Proof of Principle

- Verification and Validation

- Quality Control

- Sensitivity and Specificity Assessment

- Parameters Analysis (Humidity, Materials, Reagents etc.)

- State-of-the-Art Mold Production and Micro-Injection

- Reagent Integration (Liquid and dry reagents)

- Blister pack custom design and manufacturing

- Biocompatible Bonding Techniques

- Scalable Surface Treatment / Coating processes

- New Polymer Materials for Mass-Production

- Mass Manufacturing of Microfluidic Devices

- Fully Automated Production Lines

- Assembly of final product

Material Selection

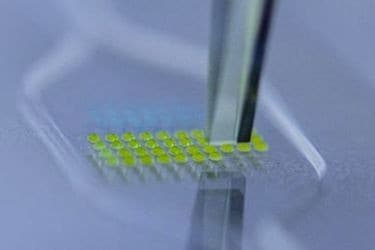

Microfluidic material selection is vital to IVD and life science consumable device design: chemical, thermal, and mechanical characteristics can create vulnerabilities and significantly affect costs at volume prodcution. For example, PDMS offers an ideal platform for development, prototyping and low-scale manufacturing; however, it is less suitable for certain applications (e.g. Molecular Dx) and high-volume production. On the other hand, thermoplastics (e.g., PMMA, PC, PS, COP, and COC) can offer better optical properties, chemical resistance, lower water absorption, and ideal conditions for high-volume manufacturing. Nevertheless, additional concerns such as autofluorescence and reagent interactions also impact efficacy for many IVD and Life science applications, with impacts ranging from optical monitoring to chemical stability. For some high volume demanding applications, TE brings more than 40 years of experience in silicon and glass microfluidic technologies. With one of the largest foundry footprints of the Silicon MEMS Industry, TE has been scaling up Silicon and Glass microfluidic technologies for several Pharmaceutical and Life Science applications.

TE offers the research and expertise you need to bring your microfluidic device to market while meeting all your performance, pricing, and time-to-market goals.

Cartridge Production Roadmaps

Production scale and manufacturability can influence material selection at various production milestones. For example, polymers such as SU-8 photoresist and PDMS are often used in the prototype and low-volume stages but may not be suitable for high-volume manufacturing. The process of selecting materials that meet user needs, regulatory demands and scalability of the program is carefully planned from early design stages to implementation and mass production by our experienced design, development and manufacturing teams.

Areas of Expertise

Characterization Studies

Characterization studies are vital tools in the evaluation of materials for consumable cartridges. These studies are comprehensive assessments of material properties and their potential impact on the microfluidic functions, reagents and IVD assay's goals. The outcome of these studies leads to the identification of processes that impact product quality, the manufacturing methods by which the cartridge can be made. They can also provide assurance that the device maintains consistent reproducibility, quality and functionality. TE has deep experience with various polymers and will guide you through the manufacturing stages of your diagnostic device development.

"Learn how we can shorten your time to market"