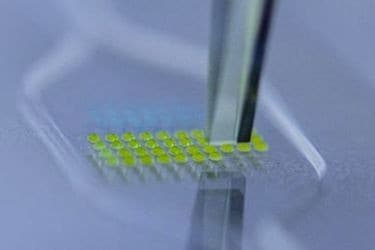

Microfluidic Lab-on-a-Chip Fluid Handling Design

Integrating a bench-top assay onto a device requires specific expertise in microfluidics including architecture design, material properties, user and instrument interfaces, and manufacturing. TE’s IVD Solutions team has a deep understanding of fluid dynamics, surface chemistry and the integration needed to make your product a commercial success.

Expertise in IVD Microfluidic Chip Design Architecture

IVD microfluidics and Lab-on-a-Chip (LOC) offer many benefits including faster analyses, high throughput, accurate measurement, and lower cost per analysis. Yet, planning and experience are key when trying to replicate an assay in a more portable, user-friendly format. TE's IVD Solutions team has worked on a wide variety of Diagnostic (Dx) and Point of Care Test (POCT) microfluidic cartridge and instrument design projects, including those with complex parameters for limits of detection, sensitivity and variability.

We Design to Balance Your Cost and Performance Targets

The commercial success of any technology depends not only on performance, but cost to manufacture at scale. We have worked on hundreds of fluid handling projects, we understand which microfluidic design technology and materials are appropriate to achieve a given protocol, and we know how to mitigate the risks of your assay. Our in-house engineering and manufacturing experts understand these product development challenges and apply their expertise to design the microfluidic geometry and materials appropriate for your device selling price, performance needs and intended use environment. Our goal is ensuring you progress from prototypes into full scale manufacturing while hitting pre-determined cost and performance targets as quickly as possible.

Areas of Expertise

- Risk mitigation analysis

- Rapid prototyping to test concepts, quick iteration times

- Reagent Integration

- Blister Pack custom design

- Surface Treatment / Functionalization

- Injection molding and CNC machining

- Bonding techniques (Solvent Bonding, heat stacking, laser welding, laser cutting, ultrasonic welding, chemical bonding, PSA, Semiconductor wafer bonding methods etc.)

- Production of small series for V&V

An End-to-End Solution to Shorten Your Time to Market

TE has the expertise, technical and manufacturing resources for bringing your concept all the way through regulatory approval as quickly as possible, so you can begin generating revenue and manufacturing at scale. We can typically accelerate your time to market because we have an array of tools in-house that allow us to test different microfluidic configurations, quickly modify designs, make prototypes and scale to volumes needed for verification and validation.