Assay transfer

Move out of IVD microfluidic development and scale up for mass manufacturing with TE Connectivity's assay transfers robust methodology.

An assay transfer can lead to a wide range of benefits and highly efficient manufacturing processes, allowing you to fulfill market demand as it develops. TE Connectivity enables the transfer and translation of conventional assay processes to microfluidic devices via onboard fluid handling techniques and the applications of onboard reagents. TE offers microfluidic designs combined with sensitive optical or electrochemical detection methods to achieve significant improvements in quantitative assessments of assay results.

Understanding assay complexity, from assay workflow verification to protocol optimization and integration. TE’s bio scientist and microfluidic engineers work together in process selection for the automation of each biological assay step.

Our technologies ensure protection and preservation of reagent stability during manufacturing, assembly, and long-term storage as well as chemical and/or biological assay functionality, fulfilling microfluidic device final intended application use.

Advantages of Microfluidic Formats

Transferring IVD assay processes to the microfluidic platform offers several significant advantages over traditional approaches—namely, an increase in throughput, lower consumption of reagents and samples, and faster antibody-antigen binding reactions. The increase in throughput is also accompanied by consistent and rapid reproducibility of microfluidic assay systems. Automated processes can improve on efficiency by reducing labor and providing electronic calibration data and traceability. Integrated reagent solutions can also simplify the entire assay process to improve on usability and complexity. TE can facilitate and assist in your IVD technology transfer and assist with production planning and forecasting.

Core Microfluidic Competencies

- Integrated regent blisters

- Dead-volume mitigation

- Air bubble mitigation & air removal vents

- Active and passive fluid motivation geometries

- Active and passive mixing devices

- Active and passive valving techniques

- On-device micro-pore filtering

- RBC/WBC segregation and whole blood separation

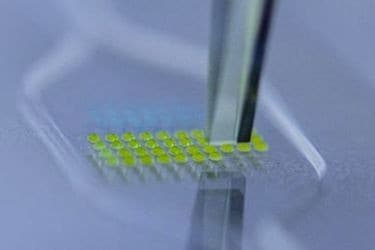

- Dried-down reagent precision spotting

- Electrochemical detection PCB integration

- Precision optical window integration

- In-house laser welded assembly

- Process development, improvement, and optimization

- Reagent blister pack manufacturing

- Design for manufacturing (DFM)

- Failure analysis and elimination

Assay Transfer Considerations

Move your assay from a development environment to a quality-controlled high-throughput system. Assay transfer failures can lead to large manufacturing delays and costs. However, problems with equipment, reagents, manufacturing techniques, and liquid handling can be alleviated. Throughout the transfer, TE monitors liquid and mechanical characteristics and prepares for variations in their composition. Assay results may change as reagent and analyte concentrations adjust during the transfer process. In addition, TE revisits the rates of calibration and verification checks, particularly in regard to the accuracy and reliability of reagent dispensing functions. TE integrates automated systems throughout the transfer to attain convenient electronic documentation, verification, and calibration scheduling benefits. Finally, TE can ensure that documentation of pre-transfer processes are accurate to establish new standard operating procedures (SOP).