Medical Device & IVD Design for Manufacturing and Assembly (DFMA)

Developers often get laser focused on innovative product design only to find out later that their creation cannot be manufactured cost effectively, wasting effort, time and money. We get our manufacturing team involved in the design process early on so we can ensure that your design will transfer to scale cost effectively.

We Begin Your Microfluidic Design Project with Your End Targets in Mind

Designers are inherently forward-thinking but sometimes come up with designs that do not consider high-volume manufacturing processes. Our experience with hundreds of microfluidic projects has taught us that no design – no matter how innovative – will see the light of day if it does not meet your cost, safety, scalability and efficacy targets. To avoid increasingly expensive surprises further along in the development process, our engineers sit down with our in-house prototyping, regulatory, clinical research and manufacturing experts to create a design risk matrix that takes production methods, materials, assembly complexity, target volumes, and cost impacts into account. Our aim is to find the commercial sweet spot for your device where performance and manufacturing cost targets intersect.

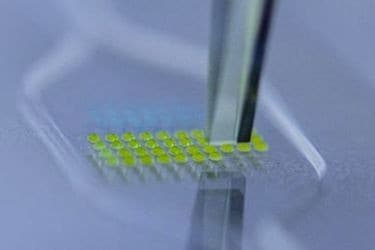

Rapid Prototyping and Iteration Allows Us to Test IVD Designs Quickly

Armed with in-house microfluidics expertise, sophisticated design/modeling software and an array of prototyping equipment, we are able to shorten the design phase for most projects by weeks or months. Our ability to iterate quickly is particularly relevant when testing a new diagnostic device design for its early integration into the market. We do this in-house as well so we can gather feedback and pivot accordingly. Design transfer checklists ensure an orderly transition from prototype to final manufacturing volumes.

We don’t just design for manufacturing, assembly, and efficacy. Our team also considers the future global regulatory path for your IVD device and associated clinical validation requirements under well-established quality guidelines.

Deep Knowledge of Biocompatibility and Reagent Properties

A bewildering array of raw materials and processing methods are available to designers and understanding their respective limitations is a science unto itself. Choosing the wrong material or processing method for your cartridge design can have a significant impact on manufacturability and assembly when scaled to higher volumes. Understanding these limitations is critical as you ramp up volume. We have worked on a wide variety of IVD cartridges and complex microfluidic design projects, always paying careful attention to:

- Raw material physical chemical properties

- Processing methods and scalability

- Reagent shelf life, use and storage conditions

- Reagent volume, concentration range and sensitivity

- Interaction between cartridge material, reagents and assembly

While the materials and assembly techniques used for early “proof of concept” prototypes may differ from those applied at higher volumes, our team always maps out the progression of your project from low to moderate to high volume from the earliest stages of the project.