Industry Tradeshow

2020 IPC APEX Expo

Please join TE at the IPC APEX Expo to learn more about our latest advancements in PC board processing technology.

February 4-6, 2020

San Diego Convention Center, Booth #2619

Smart Innovations that Connect a Better World. Join the TE Connectivity (TE) Application Tooling team at the 2020 IPC APEX Expo in booth #2619 from February 4-6 to learn about our latest advancements in PC board processing technology. Our technology is based upon decades of innovation and quality manufacturing to produce leading edge, solderless connections. From agriculture and aerospace to home appliances and automotive applications, TE Connectivity (TE) pin insertion and connector seating machines provide reliable, quality connections.

Product Portfolio

-

Connector Seating Machines (On Display at Show)

TE connector seating machines provide a faster, more reliable and less operator-intensive method for processing compliant pin connectors. Our machines handle demanding applications from daughter cards to mid-planes to back-planes, and offer fast, simple product presentation, while providing full control and monitoring of force, distance, and speed for quality assurance. The result? Quality is maximized, yield is improved, and costs are reduced. Plus, each press is programmed and run via a PC with all product, tool and process information conveniently stored in a database. During operation, all necessary adjustments to the press stroke (i.e., starting clearances, min/max force requirements, speed) are completed automatically without operator intervention. Imagine how much scrap and rework from common operator errors this will prevent.

-

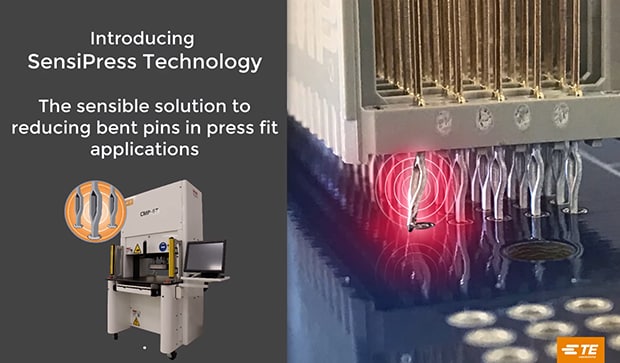

SensiPress Technology (On Display at Show)

While at the show, get an inside look at SensiPress technology, our new connector seating machine upgrade, which is designed to enhance the detection of bent pins in connector press fit applications. The high sensitivity measurement capabilities of SensiPress technology enables TE connector seating machines to more accurately measure press force and halt the seating cycle if it detects early contact with the tool, indicating that one or more pins are bent or out of alignment.

-

Pin Insertion Machines

Our pin insertion machines are designed to provide the flexibility to meet your production needs today and tomorrow. Products from TE and other manufacturers can be applied to meet your full range of production requirements. Each product is applied by a specific “quick change” product tool pack that minimizes initial cost, while maximizing platform capabilities. Most machines can be supplied with more than one insertion head to increase the number of products that can be applied. Our upper level machines can be equipped with insertion force monitoring to provide an even higher degree of quality assurance as requested in many automotive applications.

Industry Tradeshow

2020 IPC APEX Expo

Please join TE at the IPC APEX Expo to learn more about our latest advancements in PC board processing technology.

February 4-6, 2020

San Diego Convention Center, Booth #2619

Smart Innovations that Connect a Better World. Join the TE Connectivity (TE) Application Tooling team at the 2020 IPC APEX Expo in booth #2619 from February 4-6 to learn about our latest advancements in PC board processing technology. Our technology is based upon decades of innovation and quality manufacturing to produce leading edge, solderless connections. From agriculture and aerospace to home appliances and automotive applications, TE Connectivity (TE) pin insertion and connector seating machines provide reliable, quality connections.

Product Portfolio

-

Connector Seating Machines (On Display at Show)

TE connector seating machines provide a faster, more reliable and less operator-intensive method for processing compliant pin connectors. Our machines handle demanding applications from daughter cards to mid-planes to back-planes, and offer fast, simple product presentation, while providing full control and monitoring of force, distance, and speed for quality assurance. The result? Quality is maximized, yield is improved, and costs are reduced. Plus, each press is programmed and run via a PC with all product, tool and process information conveniently stored in a database. During operation, all necessary adjustments to the press stroke (i.e., starting clearances, min/max force requirements, speed) are completed automatically without operator intervention. Imagine how much scrap and rework from common operator errors this will prevent.

-

SensiPress Technology (On Display at Show)

While at the show, get an inside look at SensiPress technology, our new connector seating machine upgrade, which is designed to enhance the detection of bent pins in connector press fit applications. The high sensitivity measurement capabilities of SensiPress technology enables TE connector seating machines to more accurately measure press force and halt the seating cycle if it detects early contact with the tool, indicating that one or more pins are bent or out of alignment.

-

Pin Insertion Machines

Our pin insertion machines are designed to provide the flexibility to meet your production needs today and tomorrow. Products from TE and other manufacturers can be applied to meet your full range of production requirements. Each product is applied by a specific “quick change” product tool pack that minimizes initial cost, while maximizing platform capabilities. Most machines can be supplied with more than one insertion head to increase the number of products that can be applied. Our upper level machines can be equipped with insertion force monitoring to provide an even higher degree of quality assurance as requested in many automotive applications.