How To Select A Backshell

This brochure will serve as a general guide to help select the best product for an interconnect system.

Overview

TE Connectivity (TE) offers an extensive range of circular and rectangular backshells to meet the challenges of today’s demanding environments for Aerospace, Defense, and Marine applications. A backshell (also known as an adapter) fits on to the back of a connector to provide strain relief and cable support to help from bending or over-flexing. This brochure will serve as a general guide to help select the best product for an interconnect system. A full offering of standard product can be found on our website while TE’s product managers and design engineers are available if a customer is looking for something custom.

Intended Environment

Choosing the right backshell requires knowledge of its intended use and application. There are electrical, mechanical, and environmental considerations to ensure effective strain relief, environmental sealing, and electromagnetic interference (EMI) / radio frequency interference (RFI) over the life of the interconnect system. Below is a list of suggested qualifying questions specific to the working environment that will need to be considered.

- What is the mating connector part number or mil spec part number? In almost all cases, material and plating should match between the backshell and connector.

- Will this need to be sealed against the elements? If so, what level of sealing is required?

- What is the operating temperature required? What are the max and min temperature requirements?

- Is strain relief required?

- What EMI protection is required?

- Is a specific termination style needed?

- Does the backshell need to meet specific dimensional requirements?

- Is repairability important?

- Does the application require a specification conformance of any type or will an off the shelf product work?

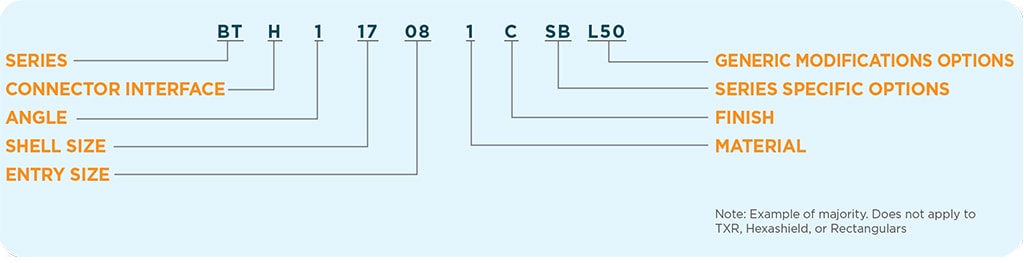

Backshell Part Number Development

TE offers an extensive standard range of backshell styles to suit a wide variety of applications and requirements. The part number, a sequence of numbers and letters that describes the adapter family (or series), size, angle, material, finish, and modifications, can be built using the standardized process outlined below. A typical part number could be developed as seen in this example below.

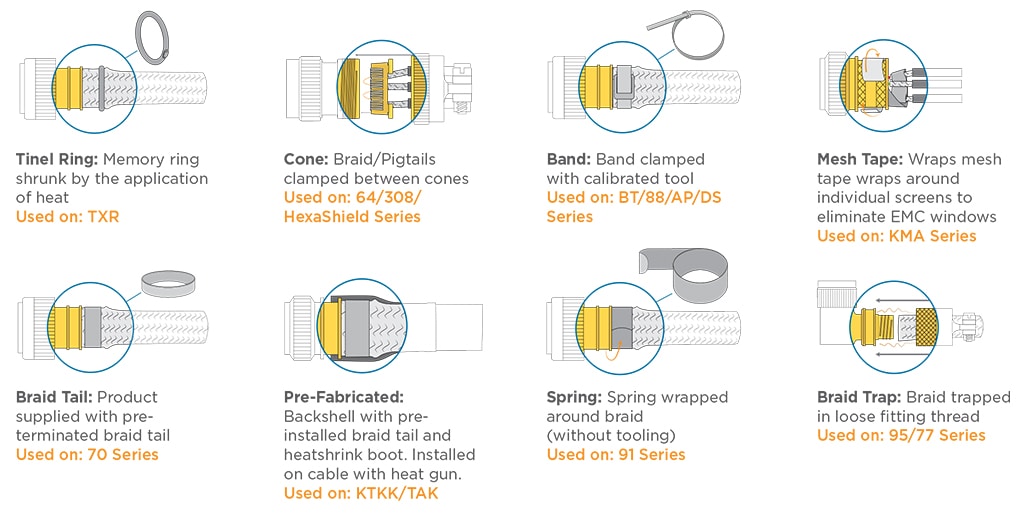

Step1 : Select the product series

TE offers several families (or series) of circular and rectangular backshells. Each part number begins with a numerical oralphanumeric prefix for the series. There is no single shield termination that will meet every customer requirement. For this reason,the graphic below outlines the different termination styles which can then be crossed to our standard series using the full catalog.

Customer selection depends on many factors including cost, screening, cable diameter, weight, strain relief. The primary factor iscable construction and how difficult the wire bundle is to work with. Customer preference, manual skill level, and repairability mustalso be considered. For most series, strain relief to help prevent the wires from pulling on the contacts and damaging thetermination can typically be achieved with a heat shrink boot or cable clamp.

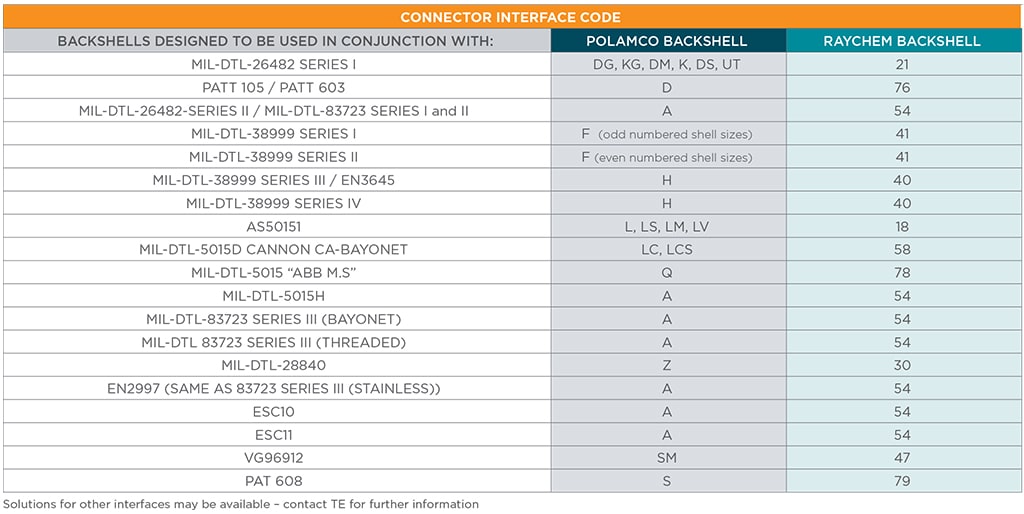

Step 2: Select the Connector Interface and Shell Size

The mating connector part number will need to be available in order to determine the interface (also known as adapter code) and shell size. These two selections will help ensure the correct backshell thread and interface dimensions fit the connector.

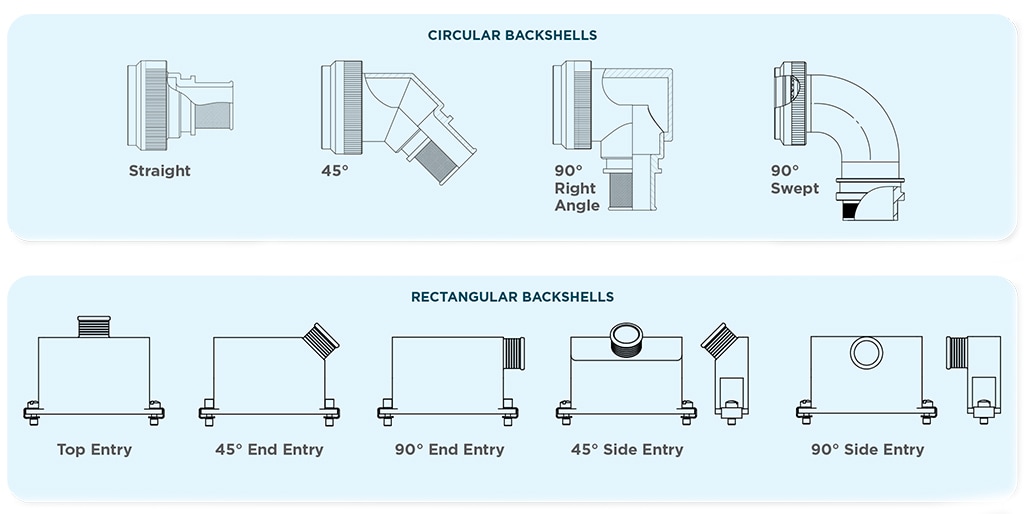

Step3: Select the Angle and Profile

Specifying the most appropriate shape is dependent on working room, repairability, cable routing, and the elimination of acute angles. In addition, the low-profile options are available if the system size needs reduced for tight spaces.

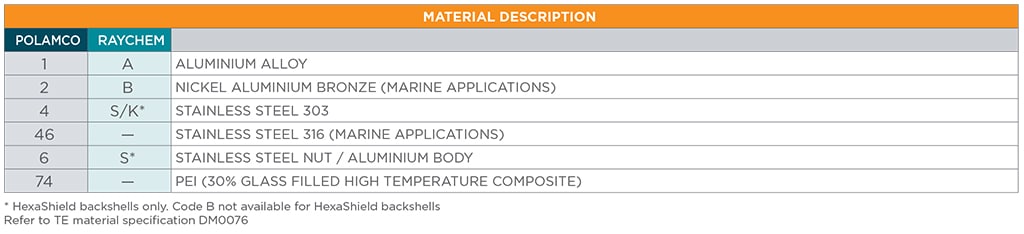

Step4: Select the Material

The mating connector part number will need to be available in order to determine the material and plating. Best practice is to match the base material and plating where possible to help prevent dissimilar metal corrosion. Composite products can help eliminate corrosion and have weight benefits over metal so should also be considered in harsh environments.

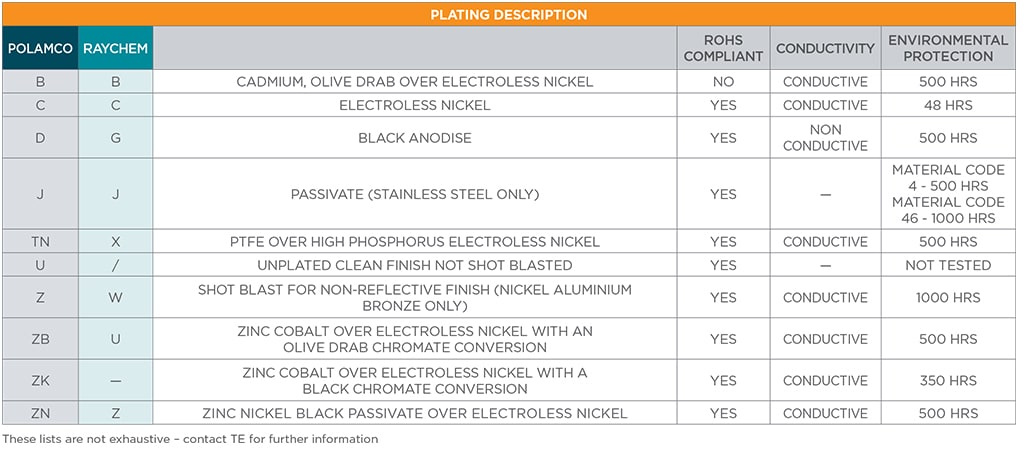

Step 5: Select the Plating

Electroless Nickel plating provides low resistance conductive finish appropriate for a non environmental application. For environmental applications where exposed to harsh conditions such as salt spray, cadmium plate over electroless nickel is recommended to provide a minimum of 500 hours of protection. If Restriction of Hazardous Substance (ROHS) compliance is required, zinc over electroless nickel is best providing the same environmental protection.

Rectangular backshells tend to be deployed in less aggressive environments so resistance against the effects of salt spray, for example, could be less of an issue. Choice of material could then be dictated by the required performance of other factors. If one of these requirements outweigh another, this may be taken into consideration when straying from best practice since one of the primary functions of plating is to act as a common middle-ground between dissimilar base materials.

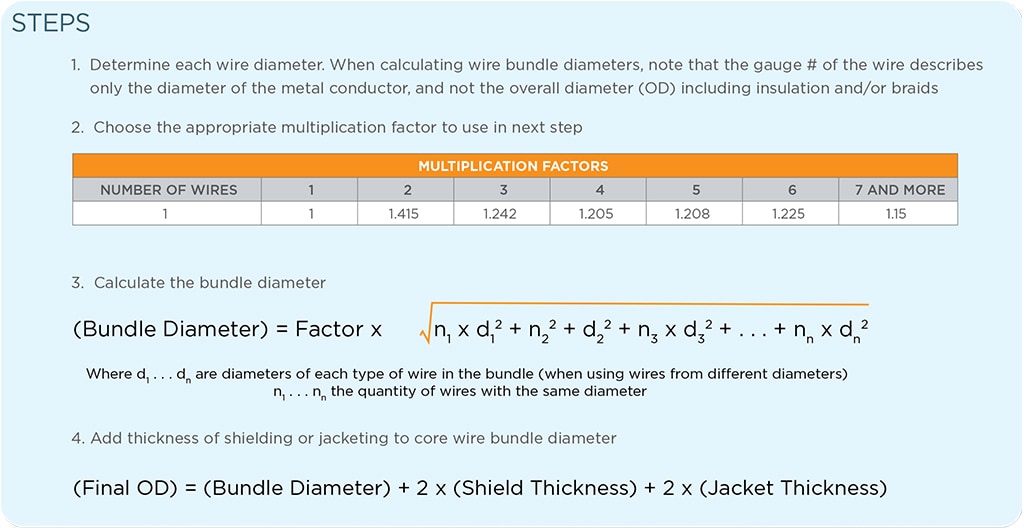

Step 6: Select the Cable Entry Diameter

An understanding of the overall cable and harness make-up is also important in the backshell selection. Accurate descriptions and measurements will determine the entry size which is where the cable enters the adapter. When selecting the backshell cable entry size, it is a good idea to err on the side of too large as an undersized cable can be enlarged with tape or a grommet to fit the cable clamp. Where it is not possible to physically measure the wire bundle diameter it can be calculated using the following steps.

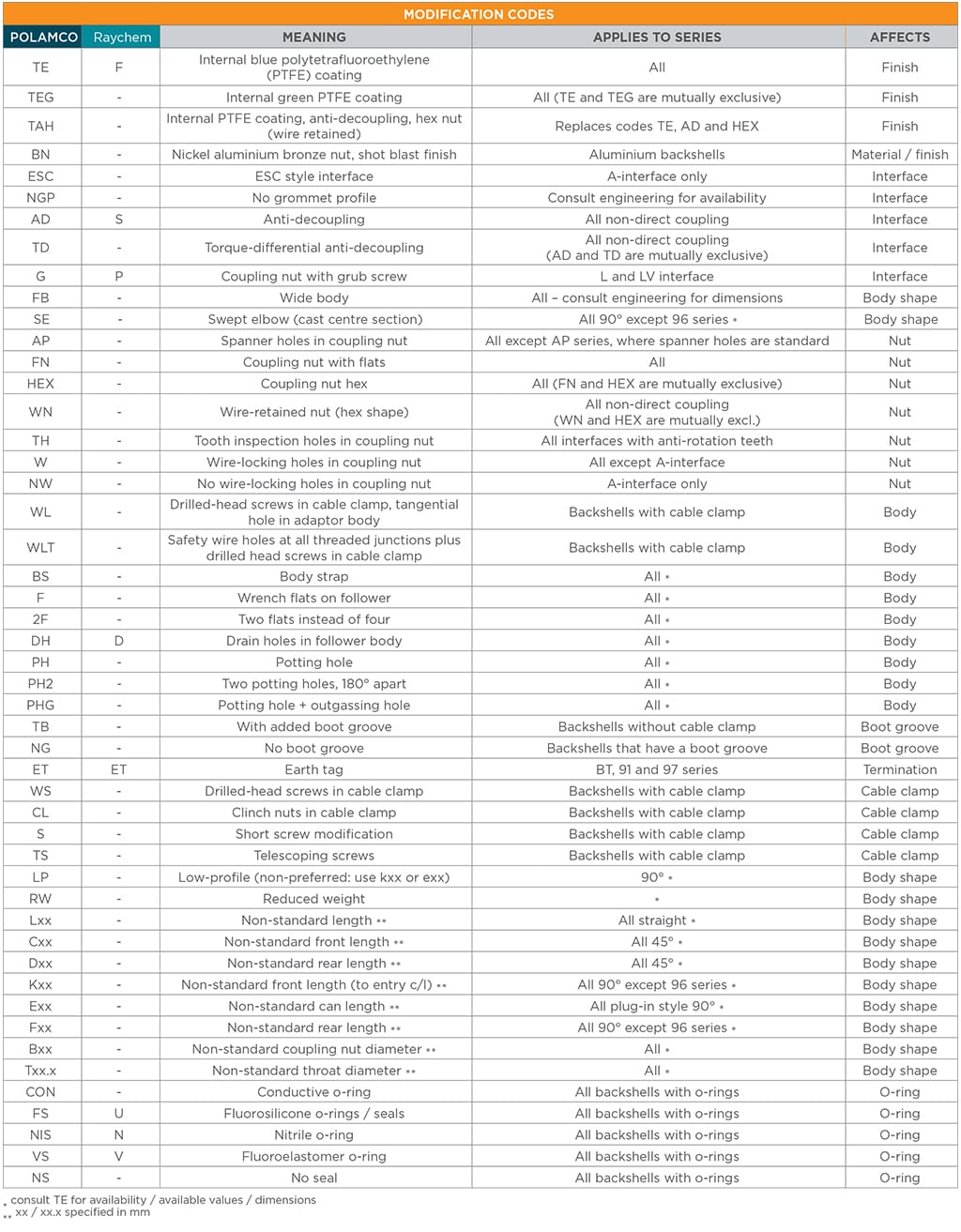

Step 7: Select Necessary Modifications

TE’s standard range of backshells can be extensively modified to create a solution to suit most customer needs. The applicable modification codes would act as a suffix and can be comprised of a series specific modification or generic standard modification. Separately for some series, the auxiliary options (such as bands and springs) may be omitted from the part number if it is not needed. Consult TE for assistance regarding the use of modifications

Virtual Backshell Sample Kit

TE Connectivity offers a range of adapter options to enable you to select the product that best meets your performance and cost requirements. Please click the link to know more about the product information, download drawings, check availability, and request samples. For a complete view of TE’s standard offering, please visit our website.