Reduce Bent Pins in Connector Press Fit Applications

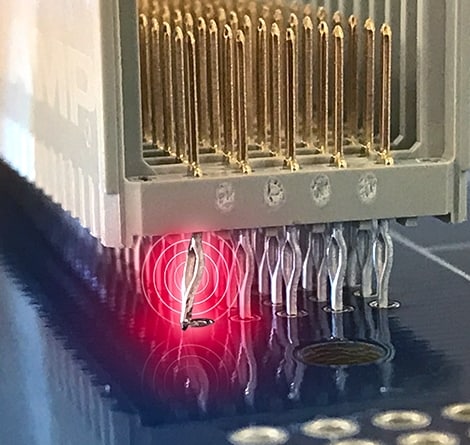

SensiPress technology is designed to enhance the detection of bent pins in connector press fit applications by reducing mechanical noise, thereby increasing accuracy, reducing scrap and simplifying troubleshooting and maintenance. As the industry moves to high-performance connectors with higher pin densities and smaller pin tails, the ability to detect bent pins at the early stage of the pressing cycle is becoming more challenging. The high sensitivity measurement capabilities of SensiPress technology enables TE Connector press fit machines to more accurately measure press force and halt the seating cycle if it detects early contact with the tool, indicating that one or more pins are bent or out of alignment.

Advantages

of SensiPress

- Higher force sensitivity: SensiPress increases the force detection capability at the initial pin contact stage. It can increase your TE press-fit machine detection precision by 5X what is currently available in the market.

- Thanks to its elegant design, the new SensiPress technology helps TE press fit machines perform at a higher level, while being simple to operate, using fewer load cells, and reducing maintenance and set-up time.

Cut through the clutter for more accurate pin detection. When only three pounds of force can crush small pins, excessive force noise can make detecting a bent pin challenging. With SensiPress technology, we optimized our load cell positioning by isolating the force sensors to eliminate excessive noise, enhancing the ability to detect bent pins and stop the press cycle before damaging expensive PC boards.

Field-installed, Servo-controlled SensiPress Upgrade

A new field-installed SensiPress upgrade kit is available for all existing TE BMEP/MEP/CBP/CMP press fit machines. Retrofits to select press fit machines can be made on-site by a trained TE Field Service Engineer. No additional software is required, and installation takes only a few hours to complete.

With the advent of smaller pins sizes, it is challenging for existing design and load cell arrays (force sensors) to detect a bent pin at the early stage of the pressing cycle. Fortunately, a field-installed SensiPress upgrade kit is now available to help reduce PC board damage.

How To Upgrade

- Contact TE or click on the "Request an Upgrade Quote" button at the top of this page.

- Provide the model and serial number of your TE Connector Press Fit machine.

- The TE Field Service department will contact you to set up an appointment.

- A TE Field Service Engineer will arrive on site to complete the upgrade in a few hours or less.