From ground vehicles to advanced aircrafts, VG standards are setting the bar in aerospace and defense solutions.

VG qualified parts from TE Connectivity (TE) are released according to the performance and functional standards agreed upon by the Federal Office of Bundeswehr Equipment, Information Technology and In-Service Support (BAAINBw) following extensive product testing. These products are trusted by both BAAINBw and other NATO (North Atlantic Treaty Organization)-aligned countries. Read on for a Q&A with Wolfgang Riederer, TE Connectivity, Manager Field Application Engineering, on the adherence to VG standards.

Why are military standards needed?

Defense standards, or military standards, regulate the development and procurement of defense materials in cases where civilian standards cannot be applied.

What are VG standards?

VG stands for Verteidigungsgeräte in German, which translates to “defense equipment” in English. These standards regulate the approval of products in the German military sector which are primarily used by the Bundeswehr. Many other countries within Europe also follow this reliable standard.

Issued by BAAINBw, VG standards contain technical and economic requirements for products and procedures in the defense sector that are not implemented in civil standards. The VG standards are recognized by the federal agencies of NATO-aligned countries, including Armasuisse (The Federal Office Defense Procurement of the Swiss Confederation) and Ministerie van Defensie (Netherlands).

How are VG standards different than MIL-SPEC?

VG standards are national standards driven by the BAAINBw (purchasing department of Germany’s Ministry of Defense), Germany’s unified armed forces, as well as related civilian administrative and procurement organizations. In that regard, they are comparable to the national military standards of the United States, often abbreviated as MIL-SPEC or MIL-STD.

VG standards are used on German military platforms. Due to the success of the German Leopard 2 main battle tank and the high quality and reliability of VG approved parts, the standard is seeing recognition and usage in 13 other European countries, as well as several non-European countries using the same vehicle platform.

VG qualified parts are released according to the performance and functional standard agreement with BAAINBw following extensive product testing. Requalification is undertaken at regular intervals to ensure products continue to meet those high standards.

How is TE Connectivity involved with VG standards?

German military VG standards are prepared by experts from the armaments sector and representatives from relevant industries. TE is contributing and participating in these regular meetings where adaptation of the standards to new trends and requirements is discussed with the Bundeswehr and OEMs. These meetings also serve as a forum to discuss and study the feasibility of technological advances together with other manufacturers.

For more than 50 years, TE has been committed to producing our products in accordance with the requested quality expectations of BAAINBw. We fulfill extensive product testing and are also aligned in regular requalification of our products to help ensure our solutions continue to meet those high-quality standards.

Further, TE helps to define and develop VG installation instructions and supports OEMs, sub-tier suppliers, and militaries for this skilled manual job.

Which products does TE offer that are VG qualified?

TE has a long history of providing end-to-end interconnection solutions for VG-95218 standard wire and cable looms and harnesses for defense applications for the air, land, and sea. These include wire and harnessing products, metal braids and some higher-temperature products, and our wire splices for both manufacturing and MRO (maintenance, repair, and overhaul) solutions.

TE further offers VG approved relays, switches, connectors, and circular backshells, which interface with the connector and provide the platform for screen termination or heat shrink boots qualified in accordance with VG-95343. We also supply a comprehensive range of heating and crimping tools and have a wealth of knowledge and expertise to help guide our customers in product selection.

Where are VG approved parts used?

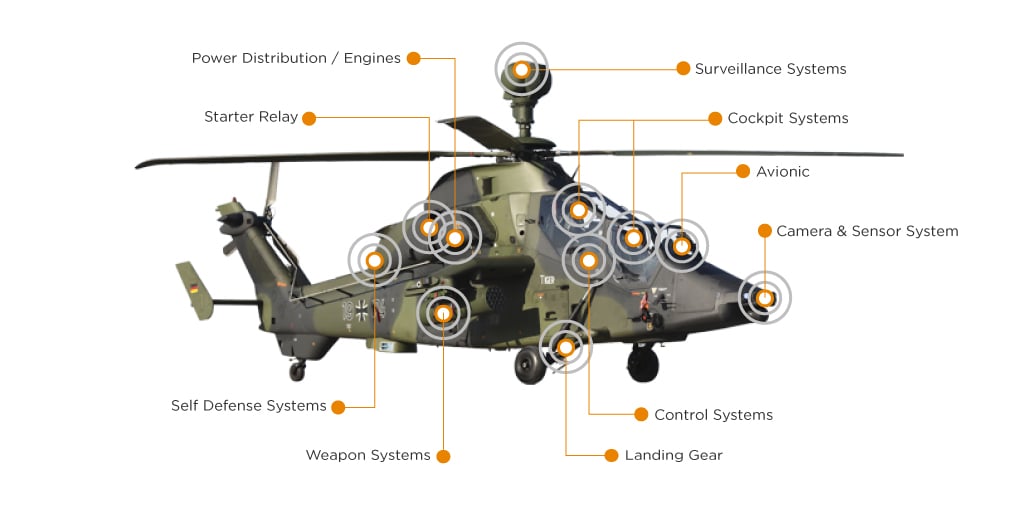

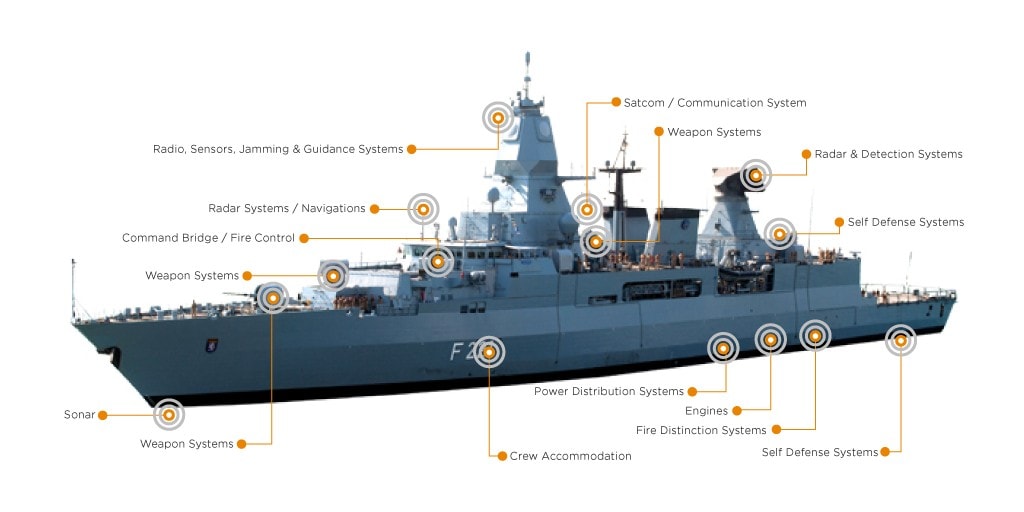

As one of the pioneers of cross-linking polymer material science and technology, TE’s wires and cables, wire splicing, and harness protection products were developed to help provide optimum mechanical protection and fluid resistance in environments where failure is not an option. Use of VG approved parts helps ensure high-quality components performance. This, in turn, helps ensure reliable systems for defense applications in the air, on land, and at sea.

VG approved components are used for virtually any interconnectivity system built on a platform that is designed and constructed in accordance with VG standards. Examples of the types of interconnectivity systems that can be built with VG standard parts include the optical system on a tank, a remote weapons system on an all-terrain vehicle, the radar system on a vessel, or missile launch systems.

The main application is on military ground vehicles, though they can be used on other platforms as well. Some examples of battlefield applications that use VG-approved parts include:

· Tanks

· All-terrain vehicles

· Military ships

· Helicopters

From ground vehicles to advanced aircrafts, VG standards are setting the bar in aerospace and defense solutions.

VG qualified parts from TE Connectivity (TE) are released according to the performance and functional standards agreed upon by the Federal Office of Bundeswehr Equipment, Information Technology and In-Service Support (BAAINBw) following extensive product testing. These products are trusted by both BAAINBw and other NATO (North Atlantic Treaty Organization)-aligned countries. Read on for a Q&A with Wolfgang Riederer, TE Connectivity, Manager Field Application Engineering, on the adherence to VG standards.

Why are military standards needed?

Defense standards, or military standards, regulate the development and procurement of defense materials in cases where civilian standards cannot be applied.

What are VG standards?

VG stands for Verteidigungsgeräte in German, which translates to “defense equipment” in English. These standards regulate the approval of products in the German military sector which are primarily used by the Bundeswehr. Many other countries within Europe also follow this reliable standard.

Issued by BAAINBw, VG standards contain technical and economic requirements for products and procedures in the defense sector that are not implemented in civil standards. The VG standards are recognized by the federal agencies of NATO-aligned countries, including Armasuisse (The Federal Office Defense Procurement of the Swiss Confederation) and Ministerie van Defensie (Netherlands).

How are VG standards different than MIL-SPEC?

VG standards are national standards driven by the BAAINBw (purchasing department of Germany’s Ministry of Defense), Germany’s unified armed forces, as well as related civilian administrative and procurement organizations. In that regard, they are comparable to the national military standards of the United States, often abbreviated as MIL-SPEC or MIL-STD.

VG standards are used on German military platforms. Due to the success of the German Leopard 2 main battle tank and the high quality and reliability of VG approved parts, the standard is seeing recognition and usage in 13 other European countries, as well as several non-European countries using the same vehicle platform.

VG qualified parts are released according to the performance and functional standard agreement with BAAINBw following extensive product testing. Requalification is undertaken at regular intervals to ensure products continue to meet those high standards.

How is TE Connectivity involved with VG standards?

German military VG standards are prepared by experts from the armaments sector and representatives from relevant industries. TE is contributing and participating in these regular meetings where adaptation of the standards to new trends and requirements is discussed with the Bundeswehr and OEMs. These meetings also serve as a forum to discuss and study the feasibility of technological advances together with other manufacturers.

For more than 50 years, TE has been committed to producing our products in accordance with the requested quality expectations of BAAINBw. We fulfill extensive product testing and are also aligned in regular requalification of our products to help ensure our solutions continue to meet those high-quality standards.

Further, TE helps to define and develop VG installation instructions and supports OEMs, sub-tier suppliers, and militaries for this skilled manual job.

Which products does TE offer that are VG qualified?

TE has a long history of providing end-to-end interconnection solutions for VG-95218 standard wire and cable looms and harnesses for defense applications for the air, land, and sea. These include wire and harnessing products, metal braids and some higher-temperature products, and our wire splices for both manufacturing and MRO (maintenance, repair, and overhaul) solutions.

TE further offers VG approved relays, switches, connectors, and circular backshells, which interface with the connector and provide the platform for screen termination or heat shrink boots qualified in accordance with VG-95343. We also supply a comprehensive range of heating and crimping tools and have a wealth of knowledge and expertise to help guide our customers in product selection.

Where are VG approved parts used?

As one of the pioneers of cross-linking polymer material science and technology, TE’s wires and cables, wire splicing, and harness protection products were developed to help provide optimum mechanical protection and fluid resistance in environments where failure is not an option. Use of VG approved parts helps ensure high-quality components performance. This, in turn, helps ensure reliable systems for defense applications in the air, on land, and at sea.

VG approved components are used for virtually any interconnectivity system built on a platform that is designed and constructed in accordance with VG standards. Examples of the types of interconnectivity systems that can be built with VG standard parts include the optical system on a tank, a remote weapons system on an all-terrain vehicle, the radar system on a vessel, or missile launch systems.

The main application is on military ground vehicles, though they can be used on other platforms as well. Some examples of battlefield applications that use VG-approved parts include:

· Tanks

· All-terrain vehicles

· Military ships

· Helicopters