APPLICATION

VG-Specification Products for Military-Grade Solutions

Compatibility, reliability, and performance are paramount in defense applications.

Your One-Stop Source for VG-Standard Products

Germany’s military VG standards are rigorous technical and techno-economic requirements for products and procedures in the defense sector. These Verteidigungsgeräte, or Defense Equipment, standards are published by the German Federal Office of Bundeswehr Equipment, Information Technology and In-Service Support (BAAINBw).

After extensive product testing, TE Connectivity’s VG-qualified parts are certified as meeting the performance and functional specifications set forth by BAAINBw. Requalification is undertaken at regular intervals to ensure our products continue to meet these high standards.

VG standards are comparable to the United States military standards (MIL-STD or MIL-SPEC). They are also recognized by countries aligned with NATO (North Atlantic Treaty Organization), including Armasuisse (The Federal Office for Defense Procurement) and Ministerie van Defensie (Netherlands).

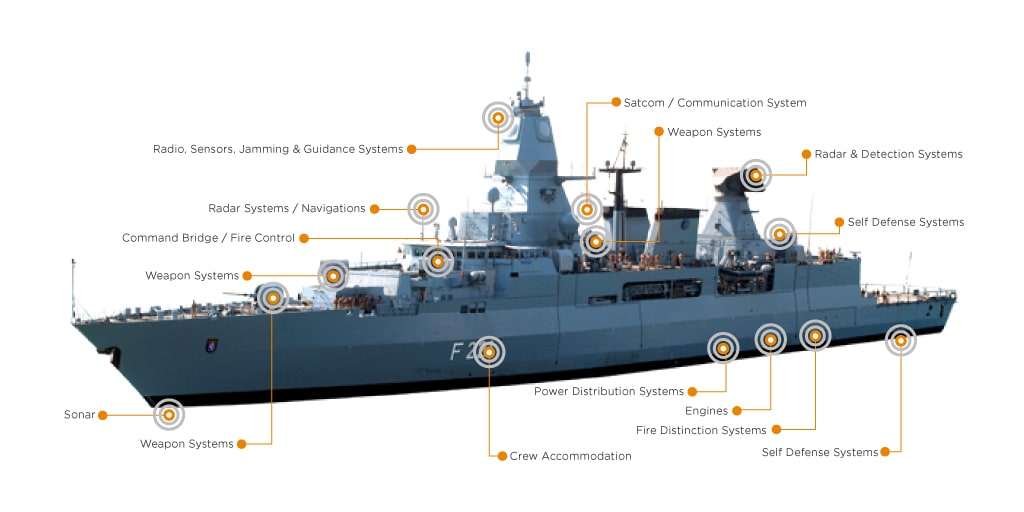

Interconnectivity on a Military Ship

Interconnect solutions for a sea-going destroyer depend on high-performance components that meet VG specifications. Vital interconnect systems include command bridge/fire control; crew accommodation; engines; fire detection; power distribution; radar system/navigation; radio, sensors, jamming, and guidance; satcom/communication; self defense; sonar; and weapons.

Integrated Harness Systems

TE's integrated harness systems have been developed for a wide range of defense and industrial applications. Each system consists of compatible components, including:

- Wire and cable

- EMI shielding braid

- Heat shrinkable components

- Adhesives

- Connector accessories

All components are tested separately and as part of an assembled system - ensuring performance reliability.

System 25

TE’s System 25 was designed to provide tough, flexible, fluid-resistant characteristics with a wide operating temperature range of -75°C to +150°C, and a balance of other properties to enhance the system performance. System 25 components are especially suited for military vehicles, aerospace and marine applications, and communication and test equipment. It is also used in the automotive and motorsport industries. Resistant to most common military fuels, oils, and greases up to +70°C, these materials are flame resistant and self-extinguishing.

System 100

TE’s System 100 was designed to provide halogen-free, low-fire hazard (LFH) characteristics. It is especially suitable for confined habitat areas in military, industrial, and civil applications. With an operating temperature of -40°C to +105°C, System 100 components are extensively used in surface and submarine vessels, as well as rail and mass transport solutions. These components are resistant to a range of fuels, oils, and greases. Components are designed to provide environmental sealing, strain relief, and flexibility. Their zero halogen and LFH characteristics ensure a low toxicity index, low smoke emission, and low corrosive gas evolution.

System 200

TE’s System 200 has an operation temperature of -55°C to +200°C and was designed for applications where continuous fluid immersion at high temperatures is required, such as military fuels, oils, and greases. Other benefits of the system include environmental sealing, flexibility, and high flame-retardancy.

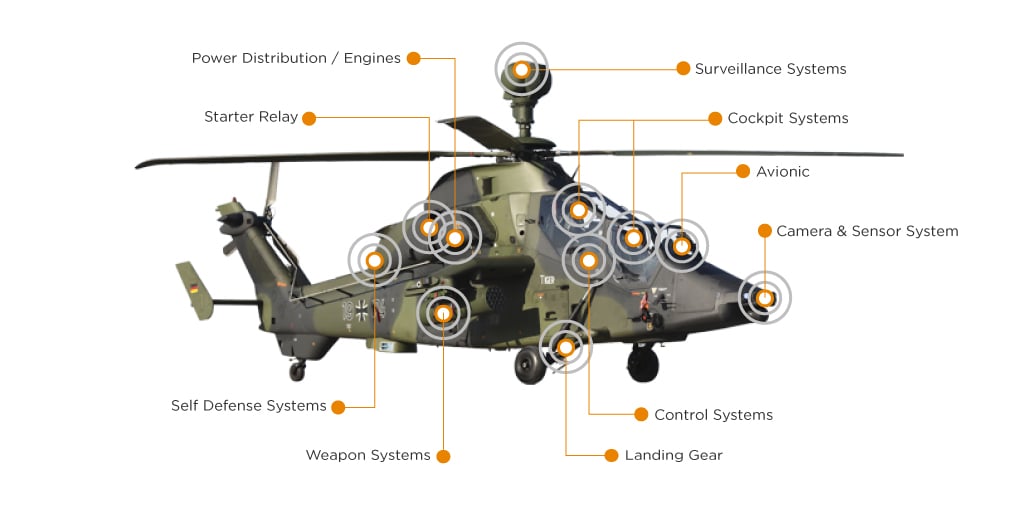

Interconnectivity on a Military Aircraft

Interconnect solutions for military aircraft depend on reliable components that meet VG specifications. Vital interconnect systems include avionics, camera and sensor, cockpit, control, landing gear, power distribution/engines, self-defense, starter relay, surveillance, and weapons.

VG 95218 Wire & Cable Products

VG 95218 Wire and Cable

Wire and cable solutions from TE stand up to challenging environments and demanding applications, while also meeting a number of global military specifications. Raychem wire and cable products carry a certificate of approval for VG 95218 standards.

VG 95343 Heat Shrink Products

VG 95343 Heat Shrink Products

Using the pioneering cross-linking technology developed by TE material scientists to enhance material performance, our heat shrink products meet global military specifications and provide protection in challenging environments and demanding applications worldwide. TE’s heat shrink System 25 and System 100 components are certified under VG 95343.