Microfluidics and the Transformation of the Diagnostics Landscape

Nearly every industry today has, at one point or another, adapted to the market to create faster, smaller, and less expensive variations of their current product. Life science is no exception, and the miniaturization of existing technologies has become the new gold standard for which corporate entities, research institutions, and startup companies are striving to achieve. The COVID-19 pandemic certainly highlighted the benefits and need for accurate rapid diagnostic testing.

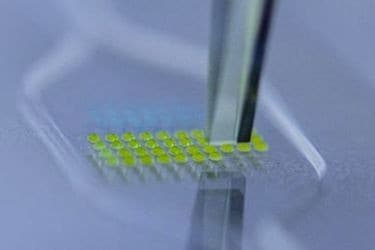

CRISPER-based diagnostics have attracted considerable interest and widespread application in point-of-care testing worldwide. A team of scientists from Stanford University developed a CRISPR “lab-on-a-chip” to detect COVID-19. “The microlab is a microfluidic chip just half the size of a credit card containing a complex network of channels narrower than the width of a human hair,” according to the study’s senior author, Juan G. Santiago, the Charles Lee Powell Foundation Professor of mechanical engineering at Stanford. Other comparative technologies to CRISPER-Cas are RT-q rapid PCR and Pulsed Controlled Amplification (PCA) systems.

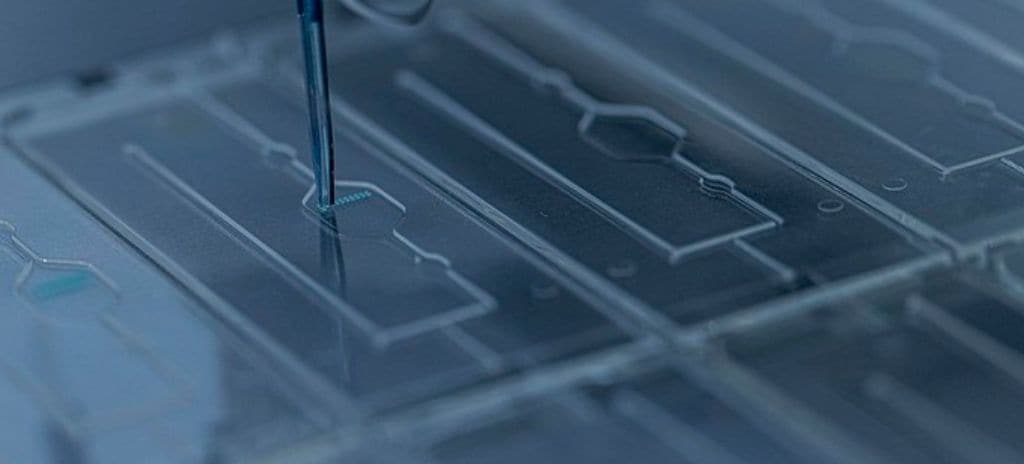

Microfluidics technologies like this can transform the diagnostics landscape, and as engineering methods improve, manufacturing becomes faster and more accurate. In the recent pandemic, point-of-care testing (POCT) empowered by Microfluidics, proved to be tremendously advantageous because it is easy to use, more accessible, faster to detect, and has high accuracy and sensitivity, reducing the burden of testing on already overtaxed healthcare systems. A microfluidic chip can be manufactured with sub-micrometer precision, making this technology excellent for applications such as DNA/RNA analysis, cell-culture, lab-on-a-chip, or organ-on-a-chip, among many others.

Lab on a Chip (LOC) Applications

Technologies such as Drop-Seq, polymerase chain reaction (PCR), or CRISPR-based diagnostics, have leveraged the benefits of microfluidics to be designed to perform complex processes with a single drop of sample. This platform can be optimized to combine functional elements such as blood filters, sample collectors, valves, channels, reaction chambers and pumps.

The “lab-on-a-chip” may seem suited for any application, but its benefits can become drawbacks depending on the process. Handling Picoliter-sized drops of fluid and attempting to consolidate an entire process onto a single chip can present an array of challenges. It’s important to consider any aspects of an assay, including target analyte concentration, chemistry, and method parameters.

Proven Experience, From Concept to Market

Microfluidic Limitations

It’s important to note that the chemistries required for a typical assay may affect its ability to run optimally in a microfluidic device. Not only can certain solvents deteriorate the chip’s material, but others may interfere with the necessary reactions. Silicon, for example, may help with prevention of PCR if left untreated, so an additional manufacturing step must be added to coat the surface, or an alternative material must be selected.

Assay chemistries can also influence the flow rate or pattern in the device. Unlike large volumes, surface tension has a significant effect on microfluidics, so the inclusion of surfactants or alcohols may change the microchip’s performance. For applications such as single-cell analysis or drug delivery, always consider the impact of this effect on drop volume, velocity, and reproducibility.

Every Cell Counts

Drop-Seq is used to analyze mRNA transcripts using droplets of fluid containing a single cell, lysis buffer and a microbead with barcoded primers. As an alternative to processing and compartmentalizing the cells in a 96 well plate, this process combines several manual steps into a single, simple device. Drop-Seq’s success depends on the reproducible production of nanoliter-sized droplets. The pressure in the system must be optimized by adjusting the pump speed that controls the rate of oil, sample and microbead release. In the optimized system, the result is a collection of single droplets containing one microbead and one cell. Single cell genomic sequencing enables robust study of complex disease. Drop-seq requires a low-cost Microfluidic setup. Lower sequencing cost. In cancer diagnostics, due to heterogeneity in Circulating Tumor Cells (CTCs), this type of analysis makes it possible to discover mechanisms not seen when studying bulk population of cells. Single-Cell analysis market is expected to be worth $6.5 billion in the US (United States) by 2025, with many potential applications such as Single-cell RNA-Seq and Single-cell-Copy Number Variation tests.

The State of the Sample

In addition to the chemistries required for reactions, it is also necessary to consider the state of the sample. In many cases, particularly in clinical assays, the sample must be pre-processed and may involve filtering, concentrating, lysing, heating, or cooling. The tiny channels can easily get clogged by cell debris or hemoglobin, so some samples must be filtered to confirm accurate results. Alternatively, technologies, such as the no-clog Wave Chips, which are designed to account for impurities in the sample, can help in avoiding additional processing steps. Therefore, easy sample preparation methods agnostic to sample types are becoming more valuable.

Many clinical assays need to detect low-abundance analytes, such as drugs or nucleic acids, and can only do so if the sample is concentrated or amplified. This is common in the detection of DNA/RNA in biological samples.

Mesa Biotech’s all-in-one Accula® system is one example of a rapid PCR-based test that provides visual results in ~35 minutes without the use of large, expensive equipment. The Accula test cartridge contains several heating elements, reservoirs, microfluidic channels, and process chemistries to allow for cell lysis, reverse transcriptase of viral RNA, amplification via PCR, and finally, detection. With high throughput (~12 test per 8hr shift per dock) and turnaround times (TAT) of 35 minutes. With ultralow levels of detection (LOD), a measure of analytic sensitivity, of about few hundred copies of the analyte per milliliter of transport media that can be reliably detected.

The Accula system and other PCR-based technologies depend on several timed incubations or reactions to prepare the sample for detection, which can make the miniaturization process complicated. However, microfluidics has enabled developers to decrease the amount of time required for these reactions because short diffusion lengths improve interactions between reagents, and the high surface-to-volume ratio provides a more efficient heat transfer and decreased reaction time.

Alternatively, some systems have developed a workaround using isothermal amplification instead of PCR. This system does not require heating and cooling to process the sample because the reactions occur at a constant temperature.

Though the COVID-19 pandemic may have put point-of-care diagnostic devices in the spotlight, these emerging technologies, and efforts to miniaturize the processes have been flourishing for years. More organizations than ever are finding novel ways to create simple, user-friendly diagnostic devices by applying microfluidics. While there have been significant advancements in the field, we’ve only begun to scratch the surface of just how effective these technologies can be. It is vital to understand when and how to use miniaturization before moving forward, the benefits when properly executed are numerous.

Conclusion

Working with a company such as the IVD Solutions team at TE, that is aligned/up to date with design factors and requirements to meet the future of rapid POC-based technologies, can help researchers respond to the market demands of faster, smaller, and more affordable microfluidics technologies, as the options expand and become more efficient.