Factors to Consider in IVD Microfluidic Device Design

You may think that when the sensor or bioassay technology for your IVD is developed and proven, the heavy lifting is over. After all, the underlying science is the important part, right?

Yes, and no. The fact is, there are more factors that go into a successful IVD design than the underlying science. The actual device needs to be designed, approved, and produced reliably in the millions—ideally with the end-users firmly in mind.

Below are a few of the most common design considerations one may encounter over the course of IVD development.

Regulatory Environment and Quality Systems

When designing an in vitro diagnostic (IVD) device, the first item to consider is the regulatory environment in which it is expected to operate. If its intended market is in the U.S., the development must be done in the context of a quality management system that is Food and Drug Administration (FDA) compliant.

If you have such a system in place, then you have a framework in which to develop a device that will be safe and effective. If, however, you do not have a quality system in place, it is imperative that you implement one prior to starting development. Backfitting a product into a quality system is not possible without repeating a lot of experiments. Working with an experienced contract development organization like TE would be a good place to start to implement a quality system.

Normal Use Conditions of the IVD

The instructions-for-use (IFU) of any approved diagnostic device include the “Intended Use” statement. It lays out the scientific and medical rationale for the test. It also identifies the sample type(s) that have been validated to work with the device. Additional material will cover maintenance requirements (if any) and required environmental conditions for the device, both at the site of use and during transport from the manufacturer to the end user. Longer-term storage may include requirements for refrigeration. Instruments will typically have temperature and humidity range specifications for effective use.

End User Requirements

User requirements mandate a thorough understanding of how the product is intended to function and any limitations on the use of the device. For example, a rapid COVID-19 antigen test is intended to be used only with symptomatic patients. Attempting to use these tests on asymptomatic populations has led to misidentification of people who appear to be negative but are in fact contagious. This can result in the spread of the disease.

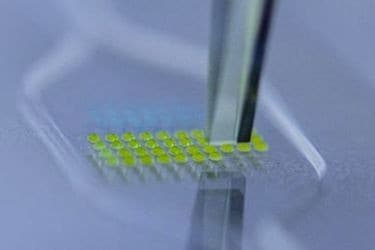

IVD Consumable Interfaces

Many diagnostic tests rely on both a consumable component and an instrument that can perform a number of functions including running the test, reading the result, and providing locally printed and/or electronic results. Understanding how to interface the consumable with the instrument along with any other reagents or ancillary equipment such as cuvettes and pipette tips is key to obtaining quality results.

Know about our expertise in IVD consumable design

Calibration and Controls

The IFU spells out calibration intervals and the frequency with which controls need to be run. They may be embedded in the software running the instrument. Temperature control within the instrument often mitigates the effects of temperature changes in the environment, but extremes of temperature can overwhelm the capacity of the instrument to buffer the changes. Some laboratories, even in developed countries, are not air conditioned, and summer indoor temperatures can exceed 37° C.

Some instruments use a washable pipette to dispense patient samples into a consumable. This works well for analytes that have limited dynamic ranges, such as drugs and some hormones. However, if the system is expected to deal with analytes such as the pregnancy biomarker human Chorionic Gonadotrophin (hCG) or some cancer markers (such as CA125) that have huge dynamic ranges that can span orders of magnitude, a phenomenon called “carryover” can complicate results by contaminating the next few results. Negative hCG samples can appear to be positive because of contamination from a very high prior sample. This can be mitigated by extra washes after certain analytes or by scheduling algorithms. Carryover of hCG into a test for another analyte such as a drug will be undetectable.

Effective Product Lifetime and Manufacturability

Diagnostic tests can have effective product lifetimes measured in years. Access to stable sources of reliable critical raw materials is essential. Antibody sources can be assured by building large pools of polyclonal antibodies or by using effectively immortal cell lines to produce monoclonal antibodies.

Manufacturability must be built into an IVD for reliability and profitability. Complex, multistep procedures that require a high level of technical ability are an invitation for trouble. It is advisable to study the manufacturing preferences and procedures that are already in place in the site where the new product is to be manufactured. Adopt as many of those practices as possible. Resist the temptation to introduce something new—use what works already. Customers who adopt a particular test and go through the qualification of the test in their own hands are not likely to be understanding if the product is backordered and cannot be supplied in a timely fashion. They will find another, more reliable product supplier.

Consumable stability is key to commercial success. Most manufacturers may release a new product with limited stability claims of about six months, but will extend that to 18 months with further stability testing data. Inventory considerations and effective use of capital tend to limit stability claims beyond 18 months. Accelerated stability studies at elevated temperatures can provide some guidance in the early stages of a product’s lifecycle, but some jurisdictions require real-time stability extending one month past the claimed stability for distribution in their markets.

IVD Packaging and Disposal

Even the packaging used in an IVD product can play unanticipated roles. A manufacturer had a product that had been performing well for several years, and then some customers complained that a key reagent had been omitted. An examination of retained examples of the component showed that about a third of the vials had no key reagent even though all the vials had been filled on the same filling line.

Further investigation showed that if the reagent had been in contact with a stopper, the stopper would absorb the reagent. Vials that happened to be stored with the contents not in contact with the stopper were fine. Only the vials that happened to land upside down were affected. Investigations reveal that the stopper manufacturer had changed the polymer composition of the stopper without notification of such a “minor” change.

In an increasingly environmentally conscious world, disposal of the used IVD devices must be considered. A new detection technology looked very promising until it was noted that it relied on a heavy metal compound. A review of disposal regulations in a few densely populated markets showed that the used IVD device that contained the heavy metal compound would need to be disposed of in a manner reminiscent of the disposal of radioactive waste with secure on-site storage and subsequent hauling away by specially licensed vendors. Not surprisingly, this detection technology never gained significant market share.

Product and Components Labeling

The IFU and product and components labeling, including advertising literature for the product, are all considered labelling by the regulatory authorities. Mislabeling an IVD product is a serious offense and can lead to a Warning Letter or even the factory being shut down by the FDA. Make sure that every claim for the IVD your organization produces can be traced back to data collected in an approved manner.

Working with an Experienced IVD Design Partner

Successful IVD development is about more than making sure the science is sound. It requires a thoughtful approach to the environment in which it will be used, the people using it, and the ways in which it will be used. Of course, there are regulatory hurdles to consider as well.