Managing Reagent Concentration in Microfluidic IVD Devices

The control and regulation of reagent concentrations in a closed IVD device is complex. Many variables impact it, including:

• The physical nature of the reagents themselves (i.e., dried vs. liquid matrices)—they may affect evaporation rates and concentrations.

• The interactions between reagents and polymer resins in microfluidic systems—they should be minimized to ensure consistent and accurate assays.

• The incorporation of statistical evaluation (e.g., guard banding) during the IVD design process and the ongoing quality control during product testing—this can ensure accurate assay results and expedite the device approval process.

These considerations (and more) are critical to an elegant, cost-effective, and competitive IVD device design for the marketplace.

Reagent Control in IVD Design

Reagent Control as Applied to Device Design

Reagents are typically water based due to the biological nature of enzymes, proteins, and cells/tissues that function in water-based environments. Water-based reagents offer the potential for hydrolysis and the delivery of a hydrogen atom, oxygen atom, or hydroxyl group to the product.

As water loss occurs, reagent concentrations increase. All plastics and most materials used in IVD device design exhibit some permeability that allows water loss. For instance, while polydimethylsiloxane (PDMS) is a hydrophobic material, it is also highly permeable to gas and water vapor and is often treated with coatings to minimize water loss. Therefore, in the context of this article, control is about ensuring:

• That the allowable water loss—and therefore the formulation at time of use—does not impact assay performance.

• That the storage materials and mechanisms used in the device minimize water loss within acceptable tolerances of the design.

Reagent Storage

Reagent storage is influenced primarily by the water vapor transmission rate (WVTR) of a material, which reflects the permeability of the material to water. The WVTR can be measured via methods that range from electrolytic and infrared sensors to more popular gravimetric methods (such as the “cup method”) that measure the change of water vapor concentration in humidity-controlled environments by weight change.

As all materials exhibit some degree of water loss, the containment materials and physical state of the reagent are of vital importance to effective storage. Most often, reagents are available in liquid or dried form. Both demand different storage conditions.

Liquid Storage

Liquid storage benefits from three main storage design concerns:

1. Material composition

2. Surface area

3. Material thickness

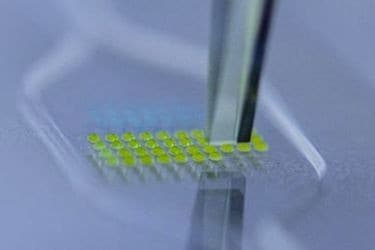

Material composition refers to the material used for storage. Foil blisters provide the best barrier and offer the lowest WVTR. Foils can be mounted directly onto microfluidic cartridges, though blister foil material choice (e.g., specialized foil blends and laminates) may impact shelf life. These materials possess various thicknesses and sealing strengths suitable for pierced or burst/push-through, peelable, and hybrid peel-push barrier reagent packaging. Foils can also be effectively stored in small volumes (less than 1mL and up to 2mL).

Plastics with low WVTR barriers can also be employed for storage. These include polypropylene (PP), high-density polyethylene (HDPE), and some cyclic olefin copolymers (COC).

Reducing the surface area of the reagent storage system reduces the amount of water loss due to permeability. This makes sense: a lower surface area means less room for water vapor transfer to occur at the reagent-material interface.

Finally, thicker materials exhibit less (or slower) water permeability.

Dried Reagents

Dried reagents (useful in lab-on-card applications) are used for reagents that cannot change concentration or are labile and degrade over time. Dried reagents require specialized packaging, assembly, and methods of resuspension (including mixing), though shelf life can be expanded.

Environmental conditions can influence the packaging. For instance, a dry surface is more environmentally stable but is less conducive to resuspension. Lyophilized beads are less environmentally stable at higher temperatures and >10% relative humidity; however, resuspension is easier due to the volume-to-surface-area ratio. Design requirements for dried reagents must therefore include packaging considerations in addition to engineered design features for containment, resuspension, mixing, and assembly.

Guard Banding

Guard banding, in a nutshell, is the process whereby a reagent concentration is intentionally changed to evaluate assay performance. It allows for the identification of acceptable reagent concentration limits for use within assays. The process returns the allowable concentration range for product functionality (as opposed to the functional range of an assay) over which the concentrations of an analyte can be measured with acceptable accuracy and precision.

The ISO/IEC 17025 standard outlines the general requirements for the competence of testing and calibration of laboratories. The standard delineates that a “decision rule” must be accompanied by reported results on statements of conformity that describe the probability of false acceptance (or the “consumer risk”) and the associated measurement of uncertainty that leads to an examination outcome. Thus, guard bands are vital for deriving acceptance and uncertainty values.

While it is possible to estimate the water loss in given containers with the particular material permeability and chamber design, including internal surface area and thickness, investigated ranges can exceed ± 10–20% concentration to have confidence that a large enough range of concentrations are viable for a particular assay evaluation. This process is typically applied to all components in each reagent formulation (together and individually) to adequately test the device’s performance under a variety of operating conditions. Multiple iterations may be necessary, for device approval application. Risk analysis tools can be used to establish potential variables.

While multiple iterations may be relevant to establish the necessary ranges, the development and testing processes do not need to be terminally applied to a point where the process fails.

The Impacts of Different Resins on Reagents

Microfluidic systems demand IVD device designs that take chemical, thermal, and physical interactions with reagents into careful consideration. Interactions between the reagent and the plastic/polymer must be minimized to avoid absorption, leaching, system degradation, and erroneous assay results. Thermoplastics that leach into the microfluidic system or absorb reagents can quickly create significant and unforeseen assay variabilities, not to mention adverse surface energy effects of the resins themselves. For microfluidic systems with specific chemical and thermal requirements, the selection of plastic resins should consider those polymers or polymer blends with the appropriate chemical properties.

Manufacturers typically report polymer chemical compatibility and resistances in hundreds of published tables that include data for acid/base and solvent resistance , optical transmissivity, thermal properties, and water absorption. The information contained in these tables is crucial to understanding the interaction between a resin and an intended reagent. These tables should be carefully reviewed during the IVD device design process to ensure that the device is stable and that the intended assay will be accurately performed.

Fluid control in microfluidic systems is dependent on surface energy and reagent formulation. Surface energy is formed from the high surface-area-to-volume ratio that occurs within fluidic systems on a microscale. It is affected by resin surfaces, including chemical treatments thereof such as plasma cleaning, vapor deposition, or textural modifications like polish. Reagent additives like detergents may create unanticipated and adverse changes in surface energy. One example of this is the potential alteration of the surface wetting ability of the resin.

When incorporating any polymer into your device design, it is essential to ensure that it will not affect assay performance. This can be confirmed through parallel testing (assay comparison) using similarly sized molded polymers with comparable surface-area-to-volume ratios.

Overlooking these considerations during the device design process can cause problems in later testing and development stages. One of the potential problems is also quite costly: a redesign of your IVD device. Fortunately, these problems can be avoided by carefully considering the chemical and physical properties of the resins used in the design.

Proven Experience, From Concept to Market

Conclusion

Reagent storage is impacted by the WVTR, and thus by the physical state of the reagent chosen for the device design. Whether liquid or dried, each reagent has its own packaging considerations. The materials used for reagent storage (and the quality control mechanisms that follow) must minimize water loss within the acceptable tolerances of the device’s design.

The control of reagent concentrations in a test system also depends upon the individual characteristics of each reagent and its interactions with the polymers used in the design. Chemical and physical properties such as permeability, leachability, absorption, reactivity, WVTR, and surface energies must all be considered. The reliability of patient assay results reported against units of a standard normal range is determined by how the testing device functions as a whole. It is essential to consider every possible resin/reagent interaction to evaluate a potential design and to avoid expensive redesigns later.