Imaging catheters have gained significant usage in various therapeutic applications due to their proven ability to reduce procedure times and enhance treatment outcomes. Consequently, the escalating demand for these devices has necessitated advancements in imaging performance. In this webinar, you will hear about the connector platform solution TE has designed for catheter development applications as well as our approach, application knowledge, and engineering expertise in developing components for imaging catheters.

Enabling signal and power transmission

TE’s offers several medical connector solutions that are designed to work in harsh medical environments - withstanding vibration, liquids and sterilization processes.

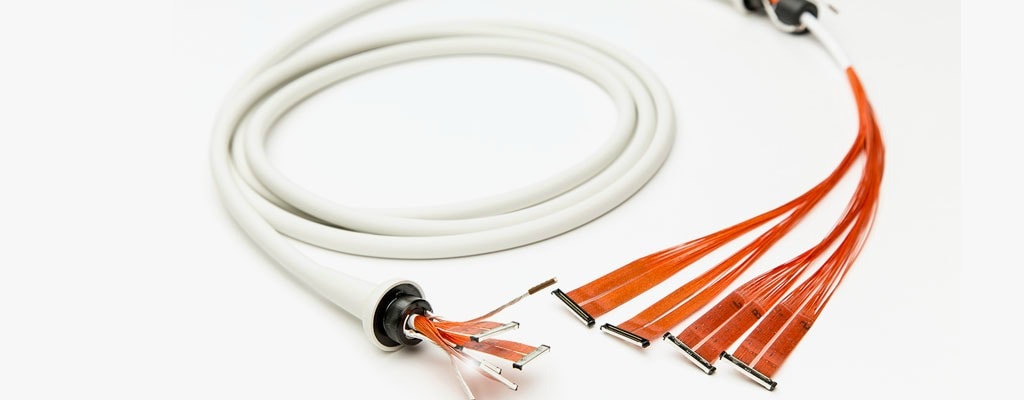

Seamless interface between cable and connector. TE offers a convenient one-stop solution for custom connectors, cables and cable assemblies that are utilized in visualization systems for catheters and various imaging systems. Our connectors, cables and cable assemblies are tailored to seamlessly interface with each other, with varying degree of complexities, enhancing their overall performance. Our capabilities include high-pin count (up to 612 pins), zero insertion force, compact sizing, fine pitch, high-durability-cycle life, and shielded connector solutions that enable power, data and signal to generate, transmit and feedback. Explore our standard connector capabilities below. Please connect with us for custom connector design needs.

CONNECTOR OFFERINGS

VERSIO™ Connector Platform

A specialized connector platform designed specifically for minimally invasive device applications, enabling the transmission of electrical power and analog signals for advanced, low-profile catheters.

TC-ZIF Connector

A high-density, zero insertion force (ZIF), wire-to-board, 260-pin connector. It’s proven reliability to support industry needs of 20,000 mating cycles and compact size makes it optimal for point-of-care ultrasound systems (POCUS).

MP456 Imaging Diagnostic I/O Connector

A high-density, interposer-based connector for use in advanced imaging systems. With 20,000 mating cycle to meet industry standard, the MP456P is suitable for the high-end cart-based medical equipment.

Hasaki 38P Connector

A 38-position high-contact count connector, while meeting a 10K mate-de-mate specification, and has high-speed digital signal capability. It was uniquely developed for use with handheld ultrasound systems, or other portable point-of-care (PoC) medical devices.

TECHNICAL RESOURCES

This paper will review how the medical industry is working to provide accurate, robust devices to improve quality of life with a focus on mobility and at-home care. You'll gain insights to the benefits and challenges in medical devices - from power and energy consumption to proper calibration, and how medical sensors can provide solutions to these common challenges.

How do you take a cable from the electrical appliances field and make it suitable for a medical device? Inspiration can come from anywhere, and at TE, our engineers worked on both the electrical and mechanical applications to create high speed cables, robust and flexible enough for medical devices. Listen to Principal Development Engineer Eugene Mayeskiy, as he discusses the electrical characterization of high speed interconnects, from minimizing crosstalk to market trends.

e

e

e

e

e

e

e

e

e

e

e

e

e

e