-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples (with Business email address)

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

- Bulk Order Purchasing

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Product Listing

This product is not currently available. For more information, including distributor inventory, please contact us.

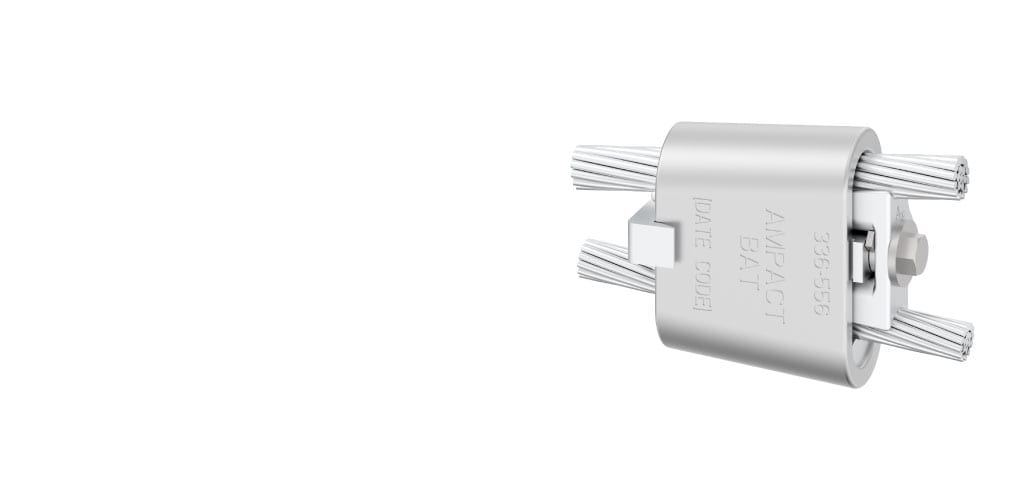

AMPACT BAT Bolt Actuated Tap Connector

- AMPACT

Product Features

-

Product Availability : Worldwide

-

Installation Technology : Energised Installation | Wedge

-

Voltage Class (kV): ≤ 500

Available from

The AMPACT BAT is the second generation of our AMPACT connectors. It combines class-leading technical strengths and user-friendly installation with industry standard tools.

"Wedge Pressure Technology” has been field-proven for over 60 years to deliver connectors with low life cycle costs for our utility customers. The “C” and wedge are made of aluminum alloys. They are used to connectsolid and stranded aluminum, aluminum alloy and stranded aluminum composite conductors including AAC, AAAC, ACSR, ACAR, AW, ACSR/AW, and ACSS. They may also be used in non-corrosive environments to connect copper conductors. During the connection process, our AMPACT BAT wedge pressure technology combines the abrading action between the conductor and connector surfaces with an inhibitor that seals the connection. This prevents air from reaching the mated material. The result is a longer-lasting, more reliable electrical connection. During the installation process, the AMPACT BAT tap connector develops and maintains the clamping force on the conductor through the residual elastic load developed in the connector. This ensures the integrity of the connection for the life of the installation. The elastic force also helps prevent creepage by compensating for expansion and contraction of the assembly during thermal cycling, while the presence of an inhibitor in the electrical interfaces protects electrical contact spots from corrosive attack during their lifetime. Designed to make tap connections on aluminum to aluminum and aluminum to copper overhead conductors for transmission, distribution, and substation applications, our new AMPACT BAT offers reliable and safe connectivity.

Our new AMPACT BAT Connectors combine class leading technical strengths and user-friendly installation with industry standard tools. They can be installed using gloved or hot stick methods instead of a special powder actuated tool. Discover how.

Key Features

- Easy to install with industry standard tools

- Taps may be used to connect multiple conductor combinations

- No damage to the conductors when installing or removing tap

- Maintains a constant force within the connection for the life of the connector, while compensating for thermal expansion or “creep”

- Solid stop for visual inspection of properly installed connector

- Industry leading electrical performance to ANSI C-119.4 Class AA

- Can be installed with standard hot sticks

AMPACT BAT Connector

Improving Grid Reliability

Know More

-

Wedge Connectors

Product Listing Page

-

Power System Connectors

Product Family Group

Frequently Asked Questions

Question: What are TE's AMPACT BAT connectors made from?

Answer: TE´s AMPACT BAT C-body, wedge, and bracket are made from aluminum alloys. The bolt is made from 304 Stainless Steel. (304 SS)

Question: For which conductor sizes can the AMPACT BAT be used?

Answer: AMPACT BAT connectors can accommodate main conductors from #6 AWG to 795 ACSR (4.11 mm - 28.14 mm). Tap conductors range from #6 AAC to 795 ACSR (4.11 mm - 28.14 mm).

Question: Can AMPACT BAT be used on copper conductors?

Answer: AMPACT BAT connectors can be used to connect aluminum to copper conductors. For copper-to-copper applications, please contact your local TE Representative.

Question: Does AMPACT BAT require any special installation tools?

Answer: No, AMPACT BAT connectors are installed using industry-standard impact wrenches. Minimum:150 ft-lbs (200 Nm) torque rating.

Question: What size socket is required for connector installation?

Answer: Below are the socket sizes for each model:

- Small Tap Family: Impact socket size 1/2in (13 mm)

- Medium Tap Family: Impact socket size 9/16in (14 mm)

- Large Tap Family: Impact socket size: 3/4in (19 mm)

Question: Does AMPACT BAT meet ANSI C119.4 Class AA?

Answer: Yes, AMPACT BAT connectors are fully tested to ANSI C119.4 Class AA (Extra-heavy Duty), which requires the ability to pass 500 current cycles at 175°C. Please contact your local TE representative for testing documentation.

Question: Can AMPACT BAT be reused?

Answer: TE recommends using a new, unused connector for each installation.

Question: Can AMPACT BAT be installed using industry-standard hot sticks?

Answer: Yes, AMPACT BAT connectors can be installed using industry-standard hot sticks in conjunction with our AMPACT BAT hot stick adapter.

Please review product documents or contact us for the latest agency approval information.

Product Type Features

-

Power Component Options Hot Stick Accessories | Insulated Cover

-

Installation Technology Energised Installation | Wedge

Configuration Features

-

Visual Inspection Yes

Electrical Characteristics

-

Voltage Class (kV) ≤ 500

Body Features

-

Compatible Conductor Material Aluminum | Copper

Dimensions

-

Compatible Conductor Range - Main (ACSR) (mm²) 13.3 – 21.2 | 21.2 | 33.6 | 53.5 | 67.4 | 85 | 85 – 107 | 107

-

Compatible Conductor Range - Main (ACSR) (AWG/kcmil) 1/0 – 1/0 | 2 – 2 | 2/0 – 2/0 | 3/0 – 3/0 | 3/0 – 4/0 | 4 – 4 | 4/0 – 4/0 | 6 – 4

-

Compatible Conductor Range - Tap (mm²) 13.3 | 21.2 | 33.6 | 53.4 | 53.5 | 67.4 | 85 | 107 | 126.68 | 135.19 | 170.46 | 177 | 177.35 | 201.42 | 203 | 241.7 | 253.35 | 280 | 281.98

-

Compatible Conductor Range - Tap (AWG/kcmil) 1/0 – 1/0 | 2 – 2 | 2/0 – 2/0 | 2– 2 | 3/0 – 3/0 | 4 – 4 | 4/0 – 4/0 | 6 – 6 | 250 – 250 | 266.8 – 266.8 | 336.4 – 336.4 | 350 – 350 | 397.5 – 397.5 | 477 – 477 | 500 – 500 | 556.5 – 556.5

-

Compatible Conductor Range - Main (mm²) 135.19 | 170.46 | 177.35 | 201.42 | 241.7 | 281.98

-

Compatible Conductor Range - Main (AWG/kcmil) 266.8 – 266.8 | 336.4 – 336.4 | 350 – 350 | 397.5 – 397.5 | 477 – 477 | 556.5 (30/7) | 556.5 – 556.5 | 605 (24/7) | 605 (24/7 – 30/19) | 605 (26/7 – 30/19) | 636 (30/19 – 24/7) | 715 (45/7) | 715 (24/7 – 30/19)

-

Compatible Conductor Range - Main (AAC) (mm²) 13.3 – 21.2 | 21.2 | 33.6 | 53.5 | 67.4 | 85 – 107 | 85 | 107

-

Compatible Conductor Range - Main (AAC) (AWG/kcmil) 1/0 – 1/0 | 2 – 2 | 2/0 – 2/0 | 3/0 – 4/0 | 3/0 – 3/0 | 4 – 4 | 4/0 – 4/0 | 6 – 4 | 715 (45/7) | 795 – 795 | 795 (26/7)

-

Compatible Conductor Range - Tap (AAC) (mm²) 13.3 | 21.2 | 33.6 | 53.5 | 67.4 | 85 | 85 – 107 | 85 – 82 | 107

-

Compatible Conductor Range - Tap (AAC) (AWG/kcmil) 1/0 – 1/0 | 2/0 – 2/0 | 2 – 2 | 3/0 – 4/0 | 3/0 – 3/0 | 4/0 – 4/0 | 4 – 4 | 6 – 6 | 266 (26/7) | 336 (26/7) | 336 (30/7) | 397 – 397 | 397 (30/7) | 397 (26/7) | 477 (26/7) | 477 (30/7) | 556 (26/7) | 556 – 556 | 636 (26/7) | 715 (26/7) | 715 (45/7) | 795 (26/7) | 795 – 795

-

Compatible Conductor Range - Tap (ACSR) (mm²) 13.3 | 21.2 | 33.6 | 53.5 | 67.4 | 85 | 85 – 107 | 107

-

Compatible Conductor Range - Tap (ACSR) (AWG/kcmil) 1/0 – 1/0 | 2 – 2 | 2/0 – 2/0 | 3/0 – 4/0 | 3/0 – 3/0 | 4/0 – 4/0 | 4 – 4 | 6 – 6

Usage Conditions

-

Operating Temperature Range (°C) -40 – 200 | 0 – 175

-

Operating Temperature Range (°F) -40 – 392 | 32 – 347

Operation/Application

-

Power Component Application Type Overhead Transmission & Distribution Connections

Product Availability

-

Product Availability Worldwide

Datasheets & Catalog Pages

- AMPACT BAT HOT STICK ACCESSORIES pdf English

- AMPACT BAT BOLT ACTUATED TAP CONNECTORS pdf English

- AMPACT BAT BOLT ACTUATED TAP CONNECTORS pdf English

Instruction Sheets

Instruction Sheet (U.S.)

- Installation Instructions - AMPACT BAT Connector pdf English

Are you sure you want to close chat?

To begin your chat with TE please enter your details