-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

- Bulk Order Purchasing

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Product Listing

This product is not currently available. For more information, including distributor inventory, please contact us.

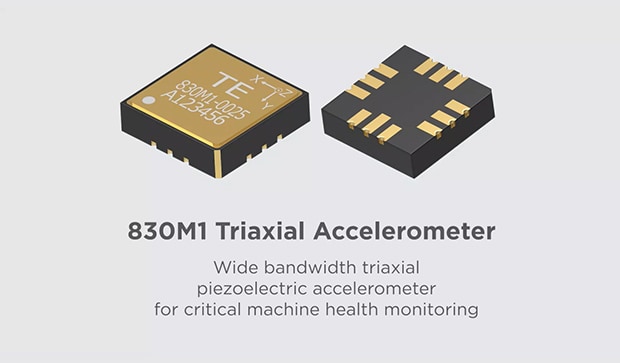

Model 830M1 Triaxial SMT Accelerometers

- MEAS

- MEAS 830

Product Features

-

Accelerometer Type : 3-Wire Voltage

-

Vibration Sensor Product Type : Piezoelectric Accelerometer

-

Number of Sensing Axes : Triaxial

-

Frequency Response (Hz): 2 to 15000

-

Full Scale Output Voltage (VDC): ±1.25

Available from

Factories are becoming more autonomous and downtime of these automated machines can be costly. Sensors are being used to capture critical performance data for improved efficiency, lower costs, and better equipment utilization of factory machinery. The triaxial embedded 830M1 accelerometer from TE Connectivity (TE) offers advanced acceleration sensing for machine health monitoring where wide bandwidth, small size, low power, and robust performance are essential.

Optimized for critical machine health monitoring the 830M1 offers an outstanding measurement bandwidth (up to 15 kHz), superior resolution and is designed with highly stable PE sensing technology, to provide long-term, reliable, stable and accurate performance for condition monitoring applications in harsh environments.

15kHz

Wide Bandwidth

X Y Z

Triaxial Measurement

2000g

±25g to ±2,000g Dynamic Ranges

Applications

- Condition monitoring

- Predictive maintenance installations

- Embedded vibration monitoring

- Impact & shock monitoring

- Data loggers

- Bearing & shaft monitoring

- Security monitoring

Benefits

- Triaxial piezoelectric (PE) accelerometer

- ±25g to ±2,000g dynamic ranges

- Wide bandwidth to 15,000Hz

- Superior resolution to MEMS devices

- Circuit board mountable, reflow solderable

- Temperature sensor included

Learn More

Infographic

The 830M1 is a wide bandwidth (up to 15kHz), triaxial piezoelectric accelerometer designed for embedded critical machine health monitoring. Watch this video to learn more.

Frequently Asked Questions

Q: What is bandwidth or frequency response of each axis of the 830M1 triaxial accelerometer?

A: Each axis offers flat response from 6 Hz to 6 kHz (±1 dB) or 2 Hz to 10 kHz (±3 dB)

Q: What is the sensing technology used in the 830M1 triaxial accelerometer design?

A: The embedded accelerometer uses piezoelectric (PE) ceramic sensing elements in shear mode.

Q: Can the 830M1 triaxial accelerometer be reflow soldered in an automated SMT process?

A: Yes, the embedded accelerometer is designed for reflow soldering to ceramic or FR4 printed-circuit boards. Recommendations for suitable reflow profiles are available in the 830M1 Datasheet.

Q: What is the measurement resolution of the 830M1 accelerometer?

A: The measurement resolution of an accelerometer is determined by its noise performance. For the 830M1, RMS (residual) noise within the passband is 6.3 to 40 mg, depending on range. Spectral noise density at 1 kHz is 45 to 280 µg/√Hz, again depending on range. For more details, please see the 830M1 Datasheet.

Q: Is a temperature sensing output also included in the 830M1 accelerometer design?

A: Yes, a Ni1000 RTD (resistance temperature detector, with positive temperature coefficient of resistance) is connected between pads 8 & 7. The temperature coefficient is 6138 ppm/K.

Q: What is the advantage of a triaxial solution in the accelerometer?

A: The device can be mounted at any orientation to the machinery being monitored. Each axis may be monitored individually. The three acceleration signals may be processed to give a single magnitude reading if required. Some defects may show different intensity in different axes – for example, a shaft may show axial or radial run-out conditions (or both).

Q: Can I use this accelerometer if I need a biaxial solution?

A: Yes, simply select 2 out of the 3 available axes, with the advantage that the mounting orientation can be more flexible than with a biaxial device.

Q: What is power consumption, excitation voltage of this sensor?

A: The supply voltage may be from 3.3 V to 5.5 V, and the maximum supply current (with each output open-circuit) is 200 µA. Max power draw under these conditions is 1.1 mW. Actual power consumption will depend on average acceleration level, and power draw may increase if the outputs are connected to low impedances.

Q: Does TE supply calibration data with each 830M1 triaxial accelerometer?

A: Yes, each axis is tested individually, and the exact sensitivity (at 80 Hz reference frequency) is supplied with each part.

Please review product documents or contact us for the latest agency approval information.

Product Type Features

-

Sensor Package Embedded

-

Accelerometer Type 3-Wire Voltage

-

Vibration Sensor Product Type Piezoelectric Accelerometer

Electrical Characteristics

-

Excitation Voltage Range (VDC) 2.8 – 5.5

-

Full Scale Output Voltage (VDC) ±1.25

Signal Characteristics

-

Frequency Response (Hz) 2 to 15000

Body Features

-

Primary Product Material Ceramic

-

Product Weight 1 g [ .12 oz ]

-

Number of Sensing Axes Triaxial

Mechanical Attachment

-

Sensor Mount Type Solder

Usage Conditions

-

Operating Temperature Range -40 – 125 °C [ -40 – 257 °F ]

Operation/Application

-

Output Current Type AC

Industry Standards

-

IP Rating IP68

Other

-

Non-Linearity (FSO) (%) ±2

-

Sensitivity Range (mV/g) .63, 1.25, 2.5, 6.3, 12.5, 25, 50

-

Overall Acceleration Range (±) (g) 25, 50, 100, 200, 500, 1000, 2000

-

Acceleration Range (±) (g) 25, 50, 100, 200, 500, 1000, 2000

-

Sensitivity (mV/g) .63, 1.25, 2.5, 6.3, 12.5, 25, 50

Reference Number

-

TE Internal Number CAT-EAC0023

CAD Files

- 3D PDF pdf 3D

- Customer View Model 2d_dxf.zip English

- Customer View Model 3d_igs.zip English

- Customer View Model 3d_stp.zip English

Datasheets & Catalog Pages

- 830M1_Triaxial_Accelerometer pdf English

Are you sure you want to close chat?

To begin your chat with TE please enter your details