Engineered for Higher Voltage Applications

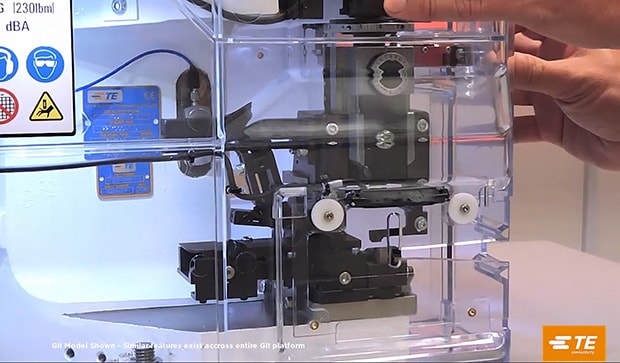

As one of the quietest terminating machines on the market, the Model G II+ is designed to process larger diameter wire sizes up to 16mm² (5.5 AWG). It's also built to deliver greater control, precision and ease of use for the operator with improved access and lighting in the under cabinet and target areas. The variable-speed option on our terminating machine provides the operator with more flexibility for challenging applications that require slower ram and feed speeds. Setup is fast and easy thanks to the machine's tool-less changeover capability, and improved guarding provides open access for quick and smooth installation of both end-feed and side-feed applicator styles. Plus, the G II+ terminating machine meets applicable CE and domestic safety requirements.

10K

10,000 lb. max crimp force

3

Modes of operation

16MM2

Processes wire sizes up to 16mm² (5.5 AWG)

Features

Advanced Design, Brushless Motor

- Able to process larger diameter wire sizes used for some high-voltage cable assemblies

- Improved lighting

- Tool-less changeover of applicators

- Precision manual crimp height adjustment

- Total and batch counter

- Reduced maintenance requirements

- Split-cycle operation

- Process wire sizes up to 16MM2 (5.5 AWG)

- Fast applicator changeover and easy adjustments

Model G II+ Terminator

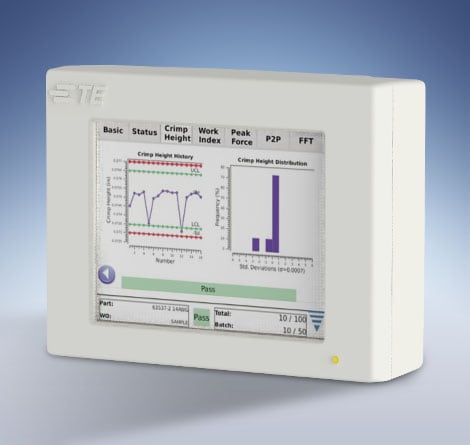

Precision Matters

All Model G II+ Terminators include precision adjustment for crimp height— an important feature, which, in combination with the optional CQM II, enables repeatable, tight crimp tolerances required by today’s demands for higher levels of quality. By simply resetting a dial, the operator can adjust crimp height in 0.013mm [.0005”] increments over a 0.457mm [.018”] range.

Crimp Quality Monitor (CQM II)

Complete Control

The user-friendly Crimp Quality II (CQM II) control panel includes simple button controls for motor powering on and off; adjusting the ram speed; jogging the motor forward or in reverse; switching to split-cycle operation; work lighting; air feed; and batch counter reset. For improved quality, the controls also detect and report errors in the machine and stop cycling when a bad crimp is detected by the CQM II.

Wire Crimping Processing:

TE Terminators and Machines

-

AMP-O-LECTRIC G II Terminator

Designed for flexibility, reliability and safety, Model G II machines offer precision adjustment for crimp height, which, in combination with the optional CQM II, enables you to maintain the tight tolerances required for high quality products.

-

AMP 3K and 5K Terminators

Terminators designed for the increased output of a semi-automatic machine at a competitive price. The most commonly requested features are standard; optional equipment is also available.

-

Model G Thru-Splice Terminator

To maximize production efficiency, this terminator is designed to apply thru-splices, by providing access to both sides of the applicator.

Dimensions

(without terminal reel and reel support)

| Height | Depth | Width | Weight |

|---|---|---|---|

| 520.7mm [20.5”] | 635.2mm [25”] | 624.3mm [24.5”] | Approx. 116 kg [255 lb] |

Specifications

| Customer Manual | 409-32035 |

|---|---|

| Capacity | 4537 kg [10,000 lb] maximum crimp force |

| Air | Pneumatic 620-760 kPa [90-100 psi] for models w/air-feed applicators (Please refer to application logs for specific air requirements) |

| Electrical | 208-240 VAC, 50/60 Hz, single phase current. Operating current is 5 amps |