Accurate terminator system for data connectivity solutions

TE Connectivity’s (TE) new semi-automatic multi-station processing system (MSPS) provides a crimping solution that improves accuracy with an in-line fixture that supports product positioning for coaxial connector systems used in data connectivity applications.

Features and Benefits

Improves Accuracy

- Cable holding fixture accurately locates the cable for consistent product positioning

- Reliable, consistent crimp performance that provides quality cable termination

Quality Process Control

- In-line fixture locates and supports cable while the cable is moved from station to station for processing

- Crimp quality monitored during each termination station

- Cable holding fixture improves crimp quality and terminal placement accuracy

Cost Savings

- This new multi-station approach provides affordability, flexibility, and the ability to ramp up or down to match manufacturing needs

- The multi-station processing system provides improved quality and processing time over hand processing without incurring the very high costs of a fully automated line

Applications

- Splicing

- Harness with ring terminal

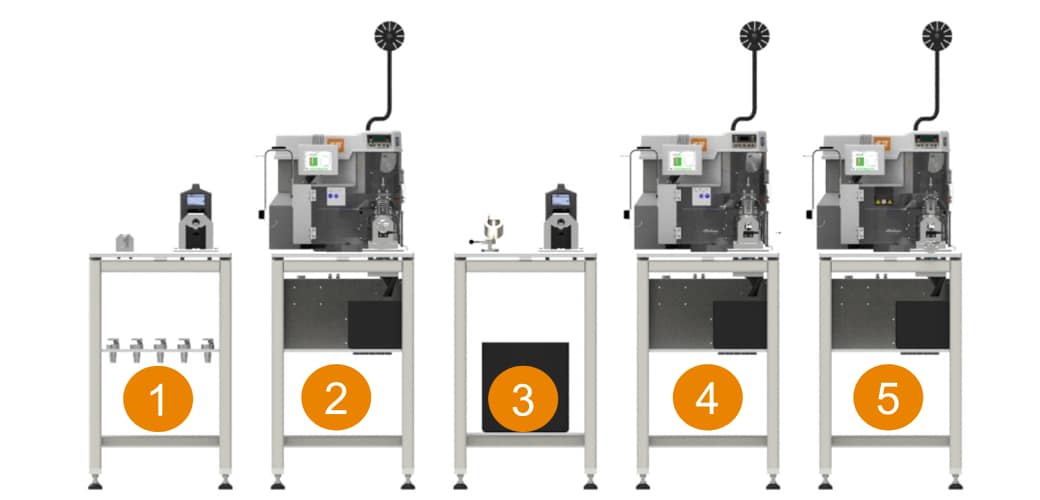

Multiple Stations

| Station 1 | Station 2 | Station 3 | Station 4 | Station 5 |

|---|---|---|---|---|

| Load cable and strip outer jacket | Crimp Ferrule | Prepare shield and dielectric | Crimp Center Contact | Subassembly Crimp |

Techinical Details

| Description | Specification |

|---|---|

| Working Condition Relative Humidity | 10-90% |

| Storage Environment Relative Humidity | 30 – 60% |

| Dimension | 700x 750 x 1400 mm |

| Weight | 235kg |

| Voltage | 220V 50Hz |

| Air Pressure | Min 6 bar |

| Nominal Crimp Speed | 3 stroke/sec |

| Programmable Pitch | Between 1.27 mm and 5.08 mm |

| Maximum Width of Pressing Area | 100mm |

| The Y Distance Difference of FPC | 10mm |

| Straight Foil Length | 50mm |

| Special Foil and Pitch | Available Upon Request |