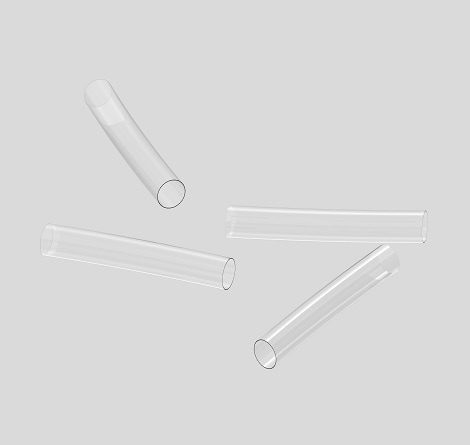

RPPM Heat Shrink Tubing : Flexible, Dual Wall, Moisture-Proof

Flexible, heat-shrink, dual-wall tubing with an integrally bonded meltable adhesive liner. Available in clear and black, the tough outer jacket with both types offers excellent mechanical strength.

Overview

RPPM is used for moisture proof encapsulation of a wide variety of components. In particular, it adheres well to PVC. The high shrink ratio allows RPPM to be used with a range of dimensions.

Clear RPPM offers excellent clarity for protection of sub strates that may need to be inspected during service. Black RPPM has a high gloss finish suitable for cosmetic applications.

Features

- 4:1 shrink ratio.

- Operating temperature from –40°C up to +85°C.

- Minimum shrink temperature: 60°C.

- Minimum full recovery temperature: 80°C.

- RoHS compliant.

Benefits

- Single component solution to insulate and protect almost all dry area splices.

- Repeatable process – not subject to operator variability.

- Low cost, high through put process equipment available cost competitive with PVC tape.

- Rapid installation up to 2000+ splices per hour.

- Low profile protection –reducing the diameter of conduit required.

- Reduced total installed cost.

- Tubing and adhesive combination for superior strain relief.

- High shrink ratios.