ELECTRO-MECHANICAL RELAY BEHAVIOR FOR ZERO CROSS APPLICATIONS

With a long history as a leading innovator in the field of electro-mechanical relays, TE Connectivity has a reputation for world-class product, application, and testing support. As the specifier of these small but intricate devices, you already know how susceptible relays can be to the various circuit and environmental conditions.

In addition to TE’s expert support in 3 regions of the world, we have accumulated a library of application notes to help understand, and design in, electro-mechanical relays. Those documents can be found on our Application Notes page. This paper is the latest in that collection.

When you are using zero-cross relay control, you learn that one relay characteristic is most important for your design; operate time. To properly anticipate the closing of the relay contacts in sync with the supply voltage you have to know how the relay responds to ambient temperature and coil voltage. For a deeper dive into the effects of temperature on relay operation in general, refer to TE’s application notes, “Temperature Considerations for DC Relays” and “Coil Voltage and Temperature Compensation.”

Operate time is defined as the time interval that elapses from energizing the relay coil in the rest state to the moment when the last output circuit (pole) is closed or opened(bounce time not included). This paper is based on testing done to demonstrate the effects of ambient temperature and coil voltage on relay operate time.

Test conditions and explanation of information/data:

All Information/Data is based on small sample size (12 relays), from the same production lot, measured over several cycles. No special measures were taken to avoid variations due to manufacturing and component variation. The test samples were new and were not subjected to endurance cycling.

Data shown are only to be considered as a snapshot of these specific samples and not a guarantee of performance for some other population of the same part numbers. The TE data-sheet is our guarantee.

The testing is performed in the laboratory environment in one mounting position (pins down) and may not accurately predict all application conditions.

No effort was made to evaluate the contact bounce during the measuring of the operation time. The operating time values are measured without the bounce. Bounce data was collected from a separate group of samples. Any variation due to measuring equipment is not included.

The coil voltage was applied using a standard DC voltage power supply. No data was collected using an alternate coil drive method.

Only one relay model has been investigated and tested to date. It may not represent similar behaviors for other Relay designs.

Testing was performed at a 4% duty cycle to eliminate any thermal impact due to coil heating. Any thermal impact with continuous ON, especially at the higher voltage on the coil is not evaluated. Continuously operating the coil at a higher voltage in elevated ambient temperature will have an impact on the performance of the relay. The coil temperature at 4% duty cycle (240 mS) can be considered close to ambient temperature during the testing.

Life testing using the different coil voltages and temperatures in this

Information/Data was not performed – so any issues regarding contact life are

not addressed here.

TE continues to investigate and to understand zero cross-application and the

impact of operate time in such applications.

Test Overview

The data was collected in groups as follows:

Operate time: 8A, 250vac, Normally Open

12 relays were placed simultaneously in the oven until thermal equilibrium was reached. Each relay was cycled approximately 1000 times with data collected at each cycle (cycle time: 0.24-sec ON/5.76 sec OFF). Data was collected at 3 coil voltages (85%, 100%, 120%). This process was then repeated at each ambient temperature (0°C, 25°C, 50°C, 75°C, 100°C).

Monostable (3-1393240-3 RT33L012)

Bistable (2-1393240-7 RT33LA12) (also known as “set” time)

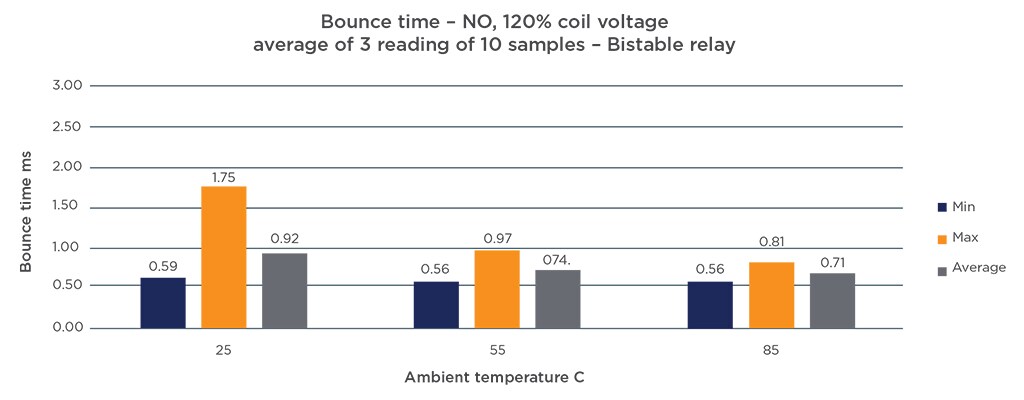

Bounce time: 100ma, 10vdc, Normally Open

10 relays were placed simultaneously in the oven until thermal equilibrium was reached. Each relay was cycled approximately 3 times with data collected at each cycle. Data were collected at 2 coil voltages (100%, 120%). This process was then repeated at each ambient temperature (25°C, 55°C, 85°C).

Monostable (3-1393240-3 RT33L012)

Bi-stable (2-1393240-7 RT33LA12) (“set”)

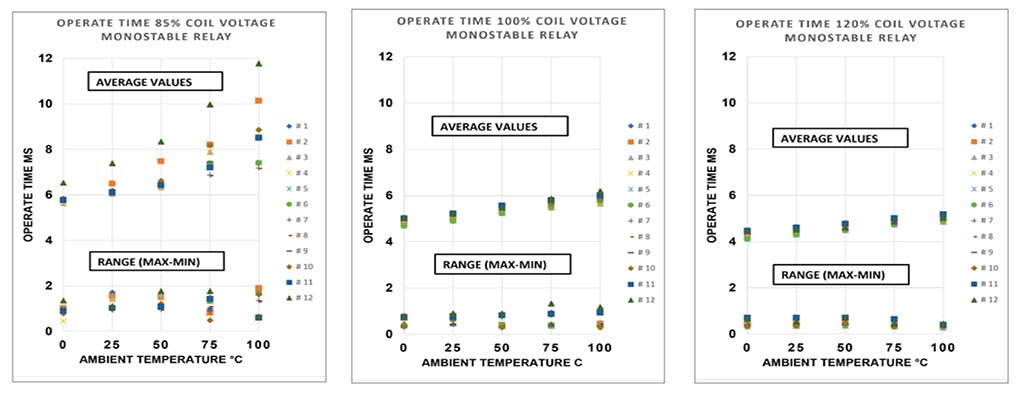

Monostable Operate Time Data

- In each graph for the monostable relay, the average operate time of each relay increases with temperature.

- As coil voltage was increased, average operate times were lower overall.

- As coil voltage increased, the variation (range) over the group decreased as well as the variation (range) of each individual relay.

- The operate times were more consistent with higher coil voltage.

- Operate times were less affected over the temperature range at higher coil voltage.

-

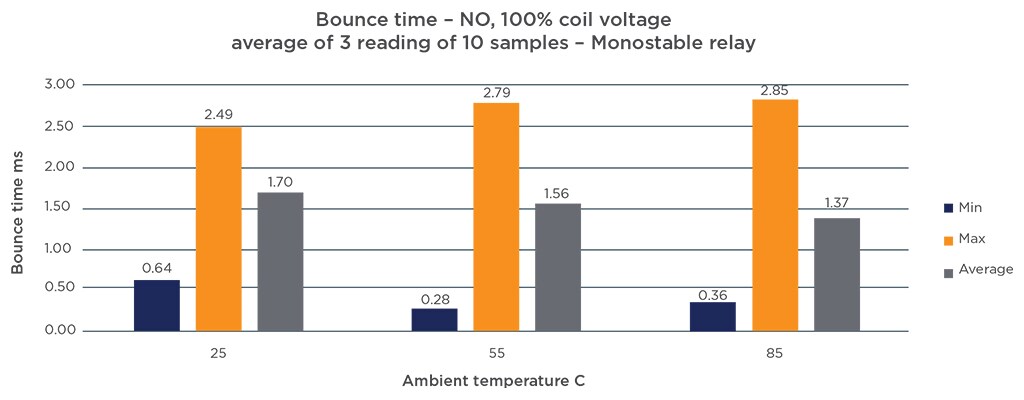

Monostable Bounce Time Data

- The bounce time data comes from a group of 30 data points: 10 monostable relays, 3 readings per relay. Data from individual relays are not shown.

- Within the group of total data (all relays), bounce times vary across all relays about 2 msec regardless of temperature or coil voltage.

- Average bounce times are slightly higher at 120% coil voltage compared to 100% coil voltage.

- The average bounce times do not appear to change significantly with temperature.

- Compared to bistable bounce times, max and average monostable bounce times are noticeably higher at all temperatures and coil voltages.

-

Bistable Operate Time Data

- Similar to the monostable relay data,

- As coil voltage was increased, average operate times were lower overall.

- As coil voltage increased, the variation (range) over the group decreased as well as the variation (range) of each individual relay.

- The operate times were more consistent with higher coil voltage.

- Operate times were less affected over the temperature range at higher coil voltage.

- At lower temperatures, the bistable operate times are slightly lower compared to monostable.

- Overall, operate times for bistable relays varied (range) slightly less from relay to relay across the temperature range.

-

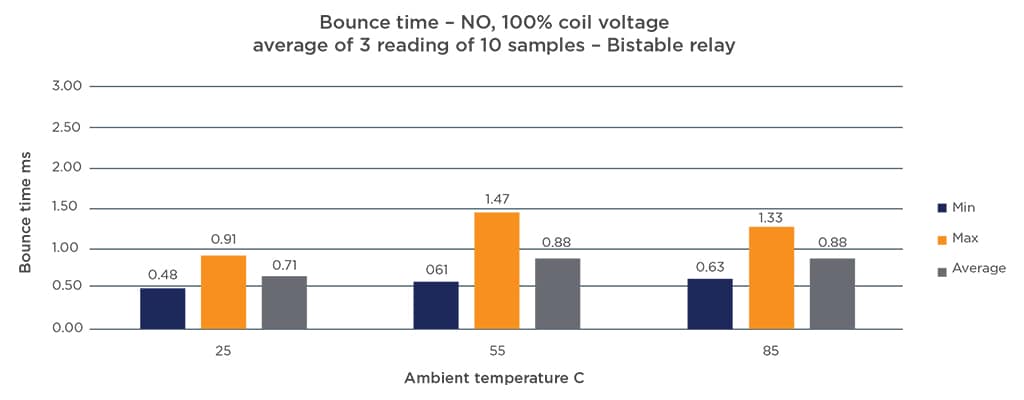

Bistable Bounce Time Data

- The bounce time data comes from a group of 10 bistable relays, 3 readings per relay: 30 data points total.

- The minimum bounce time for the group does not change significantly with changes in temperature or coil voltage.

- Compared to monostable relay bounce times, max and average bounce times for the bistable relay are noticeably smaller at all temperatures and coil voltages.

SCHRACK RELAYS

Conclusion

With respect to the relays tested for this report…

Increased ambient operating temperature likely increases the relay operate time for

any relay as well as increases the variation in operate time for each relay.

Increasing coil voltage has the effect of decreasing the operate time of any relay as

well as decreased variation in operate time. It also reduces the influence from changes

in ambient temperature.

At elevated ambient temperatures, a group of bistable relays are likely to have similar

operate times versus monostable.

An individual bistable relay tends to have a more consistent operate time compared to

its monostable counterpart (across all temperatures).

Contact bounce times in a population of monostable relays can vary more than 2

msec with little influence from coil voltage. Comparatively, a group of bistable relays

could be closer to a range of 1 msec.

Increasing coil voltage does not necessarily reduce contact bounce time.

The average bounce times do not appear to change significantly with temperature.

Monostable relay bounce times are noticeably higher at all temperatures and coil

voltages compared to bistable.