Choosing the relay materials, ratings, and styles to address design requirements

Relay contacts are available in a variety of metals and alloys, sizes and styles. There is no such thing as a universal contact. The relay user should select contact materials, ratings, and styles to meet, as precisely as possible, the requirements of a particular application. Failure to do so can result in contact problems and even early contact failure.

For example, some contact materials require an arc to keep them free of sulfidation, oxidation, and contaminates. Such materials on contacts used in a dry or low-level circuit can result in the contacts failing electrically to close the circuit, even though they make physically. The contacts may look clean, but this is deceiving. In reality, there is a very thin film of insulating sulfidation, oxidation or contaminates on the surface of the contacts. This film must be removed for circuit continuity to be established, and arcing can accomplish this. (For dry and low-level circuits, bifurcated contacts should be used.)

Applications Considerations

In some applications, the contacts may be subjected to punishing current surges which can drastically reduce their life. Consider an incandescent lamp. A 40 watt, 120V AC lamp has a current rating of .33 ampere. The resistance of the filament when cold, however, is so low that initial inrush current may be as much as 6 amps! To attempt to switch the 40 watt lamp with, say 2 amp contacts will result in early contact failure.

The same situation exists in motor and transformer applications, and in applications where significant distributed line capacitance exists. During start-up, a motor can pull 600% or more of its running current. Thus, a 3 amp motor may actually pull 18 amps or more during start-up. A contact rated at least 20 amps should be used. Additionally, when disconnected, a motor acts as a voltage generator as it slows to a stop. Depending on the motor, it can feed back into the circuit voltages well in excess of rated line voltage. These voltages appearing across the separating contacts can cause a destructive arc to exist between the contacts, which can lead to early failure of the contacts. Because of this, it is desirable to suppress the arc. (Techniques for arc suppression are discussed later in this application note.)

Transformers can present an unusual trap for an unsuspecting relay user. When power is removed from a transformer, its core may contain remanent magnetism. If power is reapplied when voltage is of the same polarity as that of the remanent magnetism, the core may go into saturation during the first half-cycle of reapplied power. As a result, inductance will be minimal and an inrush current of perhaps 1,000% may exist for a few cycles until the core comes out of saturation. Worse, if reapplied power occurs at or near zero voltage and the increasing voltage aids remanent magnetism, the core and the air gap may saturate. An inrush of perhaps 4,000% or more may result! Also, as with motor loads, when power is removed from a transformer, the transformer will develop a counter voltage which can cause a destructive arc to exist between separating contacts.

Distributed line capacitance presents particular problems for relays and their contacts. This occurs when a relay is located a considerable distance from the load to be switched. The instant the contacts close, distributed line capacitance charges before load current flows. This capacitance can appear as an initial short-circuit to the contacts, and can pull a current well in excess of load current. Prior to selecting a relay to switch a circuit when distributed line capacitance may be significant, instantaneous inrush current should be measured, and contacts selected accordingly.

Contact Materials

Fine Silver

Fine silver has the highest electrical and thermal properties of all metals. It is the best general purpose material available. However, it is affected by sulfidation. The rate of sulfidation indoors in a metropolitan area is approximately 70 micrograms per square centimeter per day. This sulfidation forms a film on the surface of the silver which increases contact interface resistance.

Because silver and silver alloys sulfidate, contact pressures must be great enough to break through this film. (Controlled arcing will also be helpful in that it burns off the sulfidation, and contact overtravel wipes away the residue.) While such pressures have no appreciable effect on silvercadmium contacts, they do result in increased material wear of fine silver contacts. Also, an interface voltage of several tenths of a volt can result with fine silver contacts because of the sulfide film. This film has been known to capture and imbed airborne dirt. Breaking through this film generates electrical noise. Because of this, fine silver contacts are not used for low-level switching, such as audio circuits. Rather, fine silver and silver alloy contacts are for use in circuits of 12 volts, 0.4 ampere, or more.

Gold-Flashed Silver

For relays which must sit idle for long periods of time before initial operation, sulfidation of silver contacts can result in an impregnable contact interface resistance. Instead of specifying silver contacts for such applications, gold-flashed silver contacts should be specified. Gold flashing on each contact results in minimal sulfidation, and provides good electrical make upon contact. Because gold has a low boiling temperature, the flashing will burn off after just a few switch cycles if arc voltage and current is exceeded. The silver underlayment is then exposed, and may develop a sulfide film. Unless this situation can be tolerated, gold-flashed contacts should not be subjected to arcing.

Gold Overlay

A common contact for use in dry-and low-level circuits is gold overlay. The overlay is of sufficient thickness that it should not wear through to the base metal unless subjected to arcing conditions.

Silver Nickel

Depending on the application, material transfer may be quite prevalent with fine silver contacts. Typically, material tends to accumulate in the center of one contact, while the loss of material on the other contact leaves a hole, or “pit.” This pitting may cause premature contact failure. In such an application, it may be desirable to use fine grain silver contacts. These contacts are alloyed with 0.15% nickel, which gives the contacts a fine grain structure. As a result, material transfer is evenly distributed across the entire surface of the contact and the contacts last longer.

Silver Cadmium Oxide

Silver cadmium oxide contacts have long been used for switching loads that produce a high energy arc. Silver cadmium oxide contacts are less electrically conductive than fine silver contacts, but have superior resistance to material transfer and material loss due to arcing. They do exhibit greater interface resistance between mated contacts, and also a slightly greater contact assembly heat rise. The minimum arc voltagerating of silver cadmium oxide is 10 volts and, like fine silver contacts, the silver in this alloy will oxidize and sulfidate. Therefore, an arc is necessary to keep these contacts clean.

Silver Tin Indium Oxide

Silver tin indium oxide contacts, although not readily available, exhibit better resistance to arc erosion and welding than silver cadmium oxide contacts. They are even less electrically conductive, though, and are harder than silver cadmium oxide contacts. They have greater interface resistance between mating contacts and, therefore, a greater voltage drop and heat rise. At the present time, silver tin indium oxide is more expensive than silver cadmium oxide, and many relay users limit its use to applications such as incandescent lamp loads and capacitors where there is a massive inrush current during contact bounce. For low and medium power resistive and inductive loads, silver cadmium oxide is still the most commonly used and is recommended by Siemens Electromechanical Components (SEC). For applications where it is believed that silver tin indium oxide should be used, contact SEC applications engineering.

Silver Copper Nickel

Silver copper nickel contacts are for use in high inrush DC applications such as incandescent lamps and capacitive loads. These contacts exhibit good resistance to welding.

Gold Silver Nickel Alloy

Gold silver nickel alloy contacts are for use in switching loads generally of less than one ampere, and are characterized by less electrical noise on make and break than fine silver contacts. Gold diffused silver contacts offer characteristics similar to gold silver nickel alloy, but are less expensive.

Palladium

Palladium contacts do not sulfidate or oxidize, and so offer extremely low electrical noise levels. They have an electrical life expectancy of approximately 10 times that of fine silver contacts. However, because of relatively poor conductivity properties, load currents are limited to about 5 amperes.

Palladium contacts require .006” to .012” overtravel to insure good wiping action. Because of this, they are used primarily on telephone-type relays—that is, relays on which the contact arms are parallel to the length of the coil, and on which such overtravel is easy to obtain. Also, palladium contacts should be bifurcated to help insure circuit continuity on contact closure.

Tungsten

Tungsten contacts are for use in high voltage applications, usually where highly repetitive switching is required. Tungsten has a melting temperature of 3,380oC which gives it excellent arc-erosion resistance.

Tungsten may develop troublesome oxide films, especially when used as the anode contact in some DC applications. Therefore, tungsten is often used as the cathode contact, and a palladium alloy used as the anode contact. Such a combination also minimizes contact interface resistance and material transfer.

Mercury

Mercury has a melting temperature of -38.87oC. Thus, as used in relays, it is in a liquid state. Mercury will cling to the surface of any clean metal, and is used as the contacts in mercury-wetted reed relays. It has good electrical conductivity and, being liquid, there is no material transfer buildup from contact to contact. Any such material transfer is negated by the fact that when the contacts open and the mercury returns to the pool in the bottom of the relay, fresh mercury takes its place at the very next switch operation. Mercury has a boiling temperature of 357oC. Because of this, mercury contacts cannot switch currents of more than a few amperes.

Contact Life

The electrical life expectancy of general purpose and power relays is generally rated to be 100,000 operations minimum, while mechanical life expectancy may be one million, 10, or even 100 million operations.

The reason electrical life is rated so low compared with mechanical life is because contact life is application dependent. The electrical rating applies to contacts switching their rated loads. When a set of contacts switches a load of less than rated value, contact life may be significantly greater. For example, 25 amp, 240V AC, 80% P.F. contacts may be expected to switch such a 25 amp load in excess of 100,000 operations. If these contacts are used to switch, say, a 5 amp, 120V AC resistive load, however, life may be in excess of a million operations. Rated electrical life also takes into consideration arc destruction of the contacts. By use of appropriate arc suppression, contact life may be lengthened. Table 1 lists some arc voltage and current values for several different metals. An arc will ignite if both minimum arc voltage and current are exceeded. However, there will be no arc if load current at a given minimum arc voltage is less than the minimum arc current for that voltage. Likewise, there will be no arc if load voltage (or counter emf) is less than the minimum arc voltage of the contact metal. As stated, an arc may be necessary in order to burn off the contacts any sulfidation, oxidation or contaminates. However, by its very nature, an arc is destructive. For maximum contact life, the arc should be suppressed as quickly as possible as soon as it ignites. Such arc suppression may be accomplished using techniques presented in this application note.

Table 1. Characteristics of Various Contact Materials.

At voltage and current values of less than those required to ignite an arc, a spark may occur between separating contacts. This spark is a capacitive discharge, and is weak compared with an arc. Even so, the spark may be sufficient to keep sulfidation, oxidation, and contaminates from building up on the contacts. (Note: arc suppression has little, if any, effect on contact sparking.)

Contact life is terminated when the contacts stick or weld, or when excessive material is lost from one or both contacts and a good electrical make is not possible. These conditions are the result of cumulative material transfer during successive switching operations, and of material loss due to splattering.

Material Transfer and Material Loss

Material transfer occurs as a result of I2 R heat. As switch contacts begin to separate, the area of contact diminishes. Load current flowing through this increasingly constricted area generates heat which causes the contact material to melt, then boil. The liquified metal tends to collect on the cathode contact because that contact is cooler than the anode contact. Material transfer also occurs during arcing. However, under this condition, material transfer is from cathode to anode—the amount of transfer being dependent on the severity and duration of the arc, and the type of contact material used. Because contact material migrates first one way, then the other, the ideal arc suppression technique would be to quench the arc just as the anode recovers all of the material lost to the cathode just prior to the arc striking. However, this is impractical even to attempt.

Material loss is due primarily to splattering of the molten and boiling metal as contacts bounce on make. Such loss can be significant over the course of tens of thousands of operations, and the only practical way to minimize it is by arc suppression. Arc suppression quickly quenches the arc, thereby holding contact temperatures lower.

In DC applications, metal migration is predictable in that one contact is always negative, and the other, positive. In AC applications where switching is at random, either contact may be negative or positive when arcing occurs. Migration will not be in the same direction each time the switch opens, and material loss from either contact should not be significant—unless load conditions cause splattering.

Not all AC applications incorporate random switching, however. In some applications, the relay is operated at a set rate or frequency. In such instances, the contacts break load current at the same approximate point on the sine wave. That is, the same contact is always positive, and the other negative at the instant of contact separation. Material transfer during arcing will always be in the same direction. In such applications, contact arc suppression may be necessary.

This is not to say that arc suppression is not needed on random-switching AC applications. On the contrary, arc suppression can help control the loss of contact material due to splattering of the molten metal. That is, when the arc is suppressed, contact temperature is held to a minimum.

Controlled arcing of short duration can be beneficial in actually achieving the rated life of the contacts. As stated, this is because such arcing burns off of the contacts any deposits that might prevent electrical make. Such control is achieved by arc suppression. Unless arcing and/or contact overtravel cleans the contacts, films may develop on the contact surfaces, or foreign matter may collect. For this reason, it is best to apply general purpose and power relays only in applications where load voltage (or counter emf) and current is in excess of the arc voltage and current ratings of those contacts.

Contact Protection

Perhaps the most popular method of quenching an arc between separating contacts is with an R-C network placed directly across the contacts. As the contacts just begin to separate and an arc ignites, load current feeding the arc will be shunted into the capacitor through the series resistance, depriving the arc of some of its energy. As a result, arc duration will be shortened and material loss will be minimized.

Figure 1. Contact Protection Diagram

Theoretically, the ideal arc suppression method would simply be a capacitor placed directly across the contacts. However, with no resistor in the circuit, when the contacts make, there is nothing to limit capacitordischarge current. This nearly instantaneous discharge current can generate a brief, but severe arc that may cause welded contacts, depending on contact material and characteristics. Thus, the resistor is necessary to limit capacitor discharge current. However, there is one drawback. That is, the resistor tends to isolate the capacitor from the very contacts the capacitor is supposed to protect. Because of this, the amount of resistance should be kept as small as possible.

Many relay users are unfamiliar with the selection of a capacitor for arc quenching service. To begin with, AC differs from DC in that AC crosses zero 120 times per second for 60 Hertz service while DC, of course, is continuous current. In AC service, the capacitor need not be as large as in DC service because the AC arc will extinguish at a zero crossover point. In DC service, the capacitor must continue to shunt load current sway from the contacts until the contacts separate far enough apart for the arc to extinguish.

Capacitor Selection

Assume a DC application of 28 volts, 5 amperes. Further assume an R-C network is needed that will result in contact voltage of perhaps 15 volts 1 msec. after the contacts have separated. Since the value of resistance should be as small as possible, a 2 ohm resistor might be chosen. At 2 ohms, peak capacitor discharge current will be 14 amperes at time zero. Depending on contact material and size, this 14 amperes may be quite acceptable for such a short period of time.

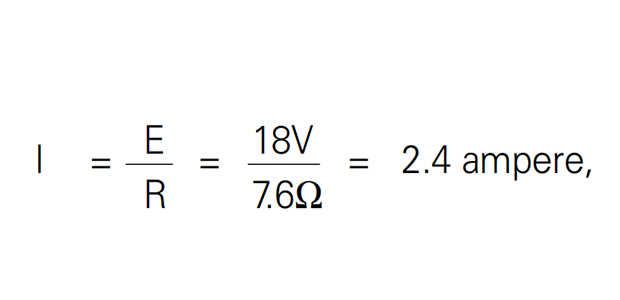

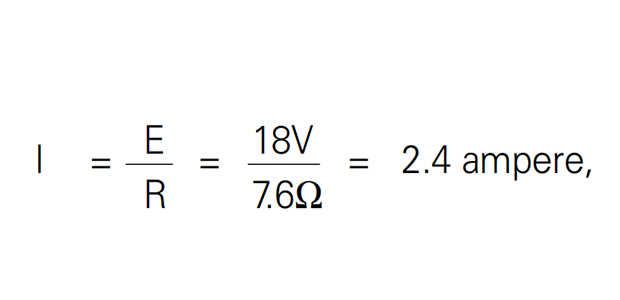

Contact voltage—that is, arc voltage—at any given instant of time is simply the sum of the voltage drop of the resistor and the capacitor voltage. Select a capacitor voltage of, say, 10 volts. The remaining 18 volts must appear across the 5.6 ohm load and the 2 ohm resistor. Thus, instantaneous capacitor current is:

and the voltage drop of the 2 ohm resistor is 4.8 volts. Arc voltage, therefore, one microsecond after contact separation is 4.8V + 10V = 14.8V, or about 53% of supply voltage.

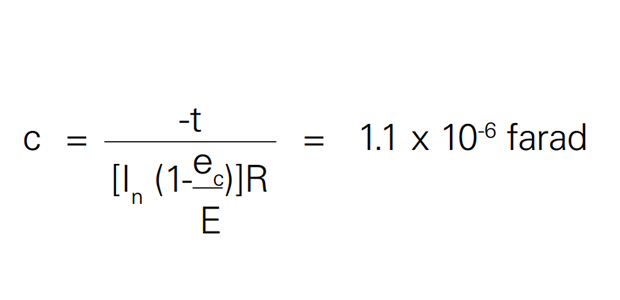

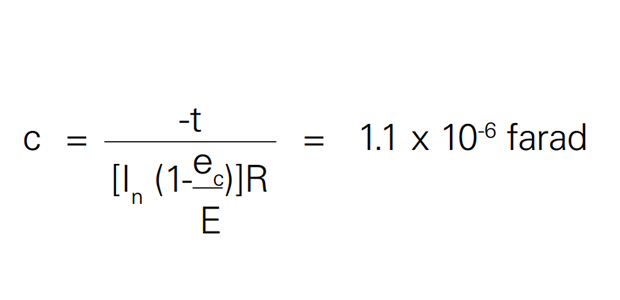

To determine the size of capacitance needed, the basic equation for capacitor voltage may be used:

ec = E(1 - ε -t/RC)

Rearranging the equation to solve for capacitance gives 1.1 µfd.

and the voltage drop of the 2 ohm resistor is 4.8 volts. Arc voltage, therefore, one microsecond after contact separation is 4.8V + 10V = 14.8V, or about 53% of supply voltage.

To determine the size of capacitance needed, the basic equation for capacitor voltage may be used:

ec = E(1 - ε -t/RC)

Rearranging the equation to solve for capacitance gives 1.1 µfd.

and the voltage drop of the 2 ohm resistor is 4.8 volts. Arc voltage, therefore, one microsecond after contact separation is 4.8V + 10V = 14.8V, or about 53% of supply voltage.

To determine the size of capacitance needed, the basic equation for capacitor voltage may be used:

ec = E(1 - ε -t/RC)

Rearranging the equation to solve for capacitance gives 1.1 µfd.

Where:

t = 1 µsec.

ec = 10 volts = capacitor voltage at time t.

E = 28 volts (for AC, use peak value).

R = 2.0 ohms.

The next question concerns capacitor construction. Can the capacitor withstand discharge surge currents? When the contacts close, the capacitor will discharge through the resistor. For a 1 µfd. capacitor and a 2 ohm resistance, the time constant is: R x C = 2 x 1 µfd. = 2.0 µsec.

To determine discharge di/dt:

where; .63 is the capacitor voltage loss during one time constant of 2.0 µsec.

This di/dt isn’t very severe and a wide variety of capacitors should be able to withstand it. However, the di/dt of a 5 ampere 240 volt AC application would be 107A/ µsec. at peak of the AC line—that is, 340 volts; and capacitor selection* should be made accordingly.

Of course, di/dt may be lowered by a larger value of resistance to limit capacitor discharge current even more. But, the greater the value of resistance, the less effect the capacitor has on the arc.

Other Arc Suppression Methods

For quenching DC arcs in certain applications, relays are available that have a permanent magnet located in close proximity to the contacts. The magnet repels the DC arc, thereby stretching the arc and causing it to extinguish quickly.

Some relay users connect a diode across the inductive load to prevent countervoltage from reaching the contacts. When the relay contacts open, the storedenergy of the inductance recirculates through the diode, not through the arc. While this is an acceptable method of protecting the contacts, it does result in lengthened hold-up time of the inductive load. For those applications that cannot tolerate lengthened hold-up time, a resistor may be placed in series with the diode. The resistor does, however, lessen the effectiveness of the diode and, usually, a compromise must be reached by trial and error.

By using a zener diode in place of the resistor, hold-up time is greatly reduced. This is because the diodes cannot turn on until the voltage across them equals the sum of their voltage drops.

In some circuits, space is at a premium and there may not be sufficient room for a zener and a regular diode. In such circuits, some designers use a metal oxide varistor. The MOV performs in a manner similar to back-to-back zener diodes. And, since the MOV is a bidirectional device, it can be used in both AC and DC circuits.

An added benefit of arc suppression is the minimization of EMI. An unsuppressed arc between contacts is an excellent noise generator. Such noise can be troublesome to sensitive components in a circuit, or within the RFI field. In worst-case conditions, EMI can cause unwanted turnon of IC logic gates, SCRs, and triacs, and can cause damage to other semiconductor devices.

*Suggested capacitor types are metalized foil and film foil. Check capacitor specifications for dv/dt and di/dt ratings.

Notes

- Measure the current inrush of the circuit to be switched before specifying the relay.

- Never parallel relay contacts to double the contact rating. Unless the relays are specially adjusted, they will not pick up and drop out simultaneously. Even if they were to be specially adjusted, they would not hold this adjustment over life.

- Paralleling Form C contacts may result in an unwanted makebefore-break arrangement. Contacts rated low level to 2 amps may be used to switch a 2 amp load. Once having done so, however, they cannot be used to switch reliably a low level load.

- In a circuit comprising a series of open relay contacts (AND logic), all but the last set of contacts to close will be dry. Likewise, in a circuit comprising a series of closed contacts, all but the first to open will be dry.

- The use of many relay contacts in series may be limited by total circuit contact resistance.

- A “low level” circuit that pulls a capacitive inrush current or develops an inductive counter emf is not low level. Worst case circuit conditions dictate contact rating, not steady state conditions.

Choosing the relay materials, ratings, and styles to address design requirements

Relay contacts are available in a variety of metals and alloys, sizes and styles. There is no such thing as a universal contact. The relay user should select contact materials, ratings, and styles to meet, as precisely as possible, the requirements of a particular application. Failure to do so can result in contact problems and even early contact failure.

For example, some contact materials require an arc to keep them free of sulfidation, oxidation, and contaminates. Such materials on contacts used in a dry or low-level circuit can result in the contacts failing electrically to close the circuit, even though they make physically. The contacts may look clean, but this is deceiving. In reality, there is a very thin film of insulating sulfidation, oxidation or contaminates on the surface of the contacts. This film must be removed for circuit continuity to be established, and arcing can accomplish this. (For dry and low-level circuits, bifurcated contacts should be used.)

Applications Considerations

In some applications, the contacts may be subjected to punishing current surges which can drastically reduce their life. Consider an incandescent lamp. A 40 watt, 120V AC lamp has a current rating of .33 ampere. The resistance of the filament when cold, however, is so low that initial inrush current may be as much as 6 amps! To attempt to switch the 40 watt lamp with, say 2 amp contacts will result in early contact failure.

The same situation exists in motor and transformer applications, and in applications where significant distributed line capacitance exists. During start-up, a motor can pull 600% or more of its running current. Thus, a 3 amp motor may actually pull 18 amps or more during start-up. A contact rated at least 20 amps should be used. Additionally, when disconnected, a motor acts as a voltage generator as it slows to a stop. Depending on the motor, it can feed back into the circuit voltages well in excess of rated line voltage. These voltages appearing across the separating contacts can cause a destructive arc to exist between the contacts, which can lead to early failure of the contacts. Because of this, it is desirable to suppress the arc. (Techniques for arc suppression are discussed later in this application note.)

Transformers can present an unusual trap for an unsuspecting relay user. When power is removed from a transformer, its core may contain remanent magnetism. If power is reapplied when voltage is of the same polarity as that of the remanent magnetism, the core may go into saturation during the first half-cycle of reapplied power. As a result, inductance will be minimal and an inrush current of perhaps 1,000% may exist for a few cycles until the core comes out of saturation. Worse, if reapplied power occurs at or near zero voltage and the increasing voltage aids remanent magnetism, the core and the air gap may saturate. An inrush of perhaps 4,000% or more may result! Also, as with motor loads, when power is removed from a transformer, the transformer will develop a counter voltage which can cause a destructive arc to exist between separating contacts.

Distributed line capacitance presents particular problems for relays and their contacts. This occurs when a relay is located a considerable distance from the load to be switched. The instant the contacts close, distributed line capacitance charges before load current flows. This capacitance can appear as an initial short-circuit to the contacts, and can pull a current well in excess of load current. Prior to selecting a relay to switch a circuit when distributed line capacitance may be significant, instantaneous inrush current should be measured, and contacts selected accordingly.

Contact Materials

Fine Silver

Fine silver has the highest electrical and thermal properties of all metals. It is the best general purpose material available. However, it is affected by sulfidation. The rate of sulfidation indoors in a metropolitan area is approximately 70 micrograms per square centimeter per day. This sulfidation forms a film on the surface of the silver which increases contact interface resistance.

Because silver and silver alloys sulfidate, contact pressures must be great enough to break through this film. (Controlled arcing will also be helpful in that it burns off the sulfidation, and contact overtravel wipes away the residue.) While such pressures have no appreciable effect on silvercadmium contacts, they do result in increased material wear of fine silver contacts. Also, an interface voltage of several tenths of a volt can result with fine silver contacts because of the sulfide film. This film has been known to capture and imbed airborne dirt. Breaking through this film generates electrical noise. Because of this, fine silver contacts are not used for low-level switching, such as audio circuits. Rather, fine silver and silver alloy contacts are for use in circuits of 12 volts, 0.4 ampere, or more.

Gold-Flashed Silver

For relays which must sit idle for long periods of time before initial operation, sulfidation of silver contacts can result in an impregnable contact interface resistance. Instead of specifying silver contacts for such applications, gold-flashed silver contacts should be specified. Gold flashing on each contact results in minimal sulfidation, and provides good electrical make upon contact. Because gold has a low boiling temperature, the flashing will burn off after just a few switch cycles if arc voltage and current is exceeded. The silver underlayment is then exposed, and may develop a sulfide film. Unless this situation can be tolerated, gold-flashed contacts should not be subjected to arcing.

Gold Overlay

A common contact for use in dry-and low-level circuits is gold overlay. The overlay is of sufficient thickness that it should not wear through to the base metal unless subjected to arcing conditions.

Silver Nickel

Depending on the application, material transfer may be quite prevalent with fine silver contacts. Typically, material tends to accumulate in the center of one contact, while the loss of material on the other contact leaves a hole, or “pit.” This pitting may cause premature contact failure. In such an application, it may be desirable to use fine grain silver contacts. These contacts are alloyed with 0.15% nickel, which gives the contacts a fine grain structure. As a result, material transfer is evenly distributed across the entire surface of the contact and the contacts last longer.

Silver Cadmium Oxide

Silver cadmium oxide contacts have long been used for switching loads that produce a high energy arc. Silver cadmium oxide contacts are less electrically conductive than fine silver contacts, but have superior resistance to material transfer and material loss due to arcing. They do exhibit greater interface resistance between mated contacts, and also a slightly greater contact assembly heat rise. The minimum arc voltagerating of silver cadmium oxide is 10 volts and, like fine silver contacts, the silver in this alloy will oxidize and sulfidate. Therefore, an arc is necessary to keep these contacts clean.

Silver Tin Indium Oxide

Silver tin indium oxide contacts, although not readily available, exhibit better resistance to arc erosion and welding than silver cadmium oxide contacts. They are even less electrically conductive, though, and are harder than silver cadmium oxide contacts. They have greater interface resistance between mating contacts and, therefore, a greater voltage drop and heat rise. At the present time, silver tin indium oxide is more expensive than silver cadmium oxide, and many relay users limit its use to applications such as incandescent lamp loads and capacitors where there is a massive inrush current during contact bounce. For low and medium power resistive and inductive loads, silver cadmium oxide is still the most commonly used and is recommended by Siemens Electromechanical Components (SEC). For applications where it is believed that silver tin indium oxide should be used, contact SEC applications engineering.

Silver Copper Nickel

Silver copper nickel contacts are for use in high inrush DC applications such as incandescent lamps and capacitive loads. These contacts exhibit good resistance to welding.

Gold Silver Nickel Alloy

Gold silver nickel alloy contacts are for use in switching loads generally of less than one ampere, and are characterized by less electrical noise on make and break than fine silver contacts. Gold diffused silver contacts offer characteristics similar to gold silver nickel alloy, but are less expensive.

Palladium

Palladium contacts do not sulfidate or oxidize, and so offer extremely low electrical noise levels. They have an electrical life expectancy of approximately 10 times that of fine silver contacts. However, because of relatively poor conductivity properties, load currents are limited to about 5 amperes.

Palladium contacts require .006” to .012” overtravel to insure good wiping action. Because of this, they are used primarily on telephone-type relays—that is, relays on which the contact arms are parallel to the length of the coil, and on which such overtravel is easy to obtain. Also, palladium contacts should be bifurcated to help insure circuit continuity on contact closure.

Tungsten

Tungsten contacts are for use in high voltage applications, usually where highly repetitive switching is required. Tungsten has a melting temperature of 3,380oC which gives it excellent arc-erosion resistance.

Tungsten may develop troublesome oxide films, especially when used as the anode contact in some DC applications. Therefore, tungsten is often used as the cathode contact, and a palladium alloy used as the anode contact. Such a combination also minimizes contact interface resistance and material transfer.

Mercury

Mercury has a melting temperature of -38.87oC. Thus, as used in relays, it is in a liquid state. Mercury will cling to the surface of any clean metal, and is used as the contacts in mercury-wetted reed relays. It has good electrical conductivity and, being liquid, there is no material transfer buildup from contact to contact. Any such material transfer is negated by the fact that when the contacts open and the mercury returns to the pool in the bottom of the relay, fresh mercury takes its place at the very next switch operation. Mercury has a boiling temperature of 357oC. Because of this, mercury contacts cannot switch currents of more than a few amperes.

Contact Life

The electrical life expectancy of general purpose and power relays is generally rated to be 100,000 operations minimum, while mechanical life expectancy may be one million, 10, or even 100 million operations.

The reason electrical life is rated so low compared with mechanical life is because contact life is application dependent. The electrical rating applies to contacts switching their rated loads. When a set of contacts switches a load of less than rated value, contact life may be significantly greater. For example, 25 amp, 240V AC, 80% P.F. contacts may be expected to switch such a 25 amp load in excess of 100,000 operations. If these contacts are used to switch, say, a 5 amp, 120V AC resistive load, however, life may be in excess of a million operations. Rated electrical life also takes into consideration arc destruction of the contacts. By use of appropriate arc suppression, contact life may be lengthened. Table 1 lists some arc voltage and current values for several different metals. An arc will ignite if both minimum arc voltage and current are exceeded. However, there will be no arc if load current at a given minimum arc voltage is less than the minimum arc current for that voltage. Likewise, there will be no arc if load voltage (or counter emf) is less than the minimum arc voltage of the contact metal. As stated, an arc may be necessary in order to burn off the contacts any sulfidation, oxidation or contaminates. However, by its very nature, an arc is destructive. For maximum contact life, the arc should be suppressed as quickly as possible as soon as it ignites. Such arc suppression may be accomplished using techniques presented in this application note.

Table 1. Characteristics of Various Contact Materials.

At voltage and current values of less than those required to ignite an arc, a spark may occur between separating contacts. This spark is a capacitive discharge, and is weak compared with an arc. Even so, the spark may be sufficient to keep sulfidation, oxidation, and contaminates from building up on the contacts. (Note: arc suppression has little, if any, effect on contact sparking.)

Contact life is terminated when the contacts stick or weld, or when excessive material is lost from one or both contacts and a good electrical make is not possible. These conditions are the result of cumulative material transfer during successive switching operations, and of material loss due to splattering.

Material Transfer and Material Loss

Material transfer occurs as a result of I2 R heat. As switch contacts begin to separate, the area of contact diminishes. Load current flowing through this increasingly constricted area generates heat which causes the contact material to melt, then boil. The liquified metal tends to collect on the cathode contact because that contact is cooler than the anode contact. Material transfer also occurs during arcing. However, under this condition, material transfer is from cathode to anode—the amount of transfer being dependent on the severity and duration of the arc, and the type of contact material used. Because contact material migrates first one way, then the other, the ideal arc suppression technique would be to quench the arc just as the anode recovers all of the material lost to the cathode just prior to the arc striking. However, this is impractical even to attempt.

Material loss is due primarily to splattering of the molten and boiling metal as contacts bounce on make. Such loss can be significant over the course of tens of thousands of operations, and the only practical way to minimize it is by arc suppression. Arc suppression quickly quenches the arc, thereby holding contact temperatures lower.

In DC applications, metal migration is predictable in that one contact is always negative, and the other, positive. In AC applications where switching is at random, either contact may be negative or positive when arcing occurs. Migration will not be in the same direction each time the switch opens, and material loss from either contact should not be significant—unless load conditions cause splattering.

Not all AC applications incorporate random switching, however. In some applications, the relay is operated at a set rate or frequency. In such instances, the contacts break load current at the same approximate point on the sine wave. That is, the same contact is always positive, and the other negative at the instant of contact separation. Material transfer during arcing will always be in the same direction. In such applications, contact arc suppression may be necessary.

This is not to say that arc suppression is not needed on random-switching AC applications. On the contrary, arc suppression can help control the loss of contact material due to splattering of the molten metal. That is, when the arc is suppressed, contact temperature is held to a minimum.

Controlled arcing of short duration can be beneficial in actually achieving the rated life of the contacts. As stated, this is because such arcing burns off of the contacts any deposits that might prevent electrical make. Such control is achieved by arc suppression. Unless arcing and/or contact overtravel cleans the contacts, films may develop on the contact surfaces, or foreign matter may collect. For this reason, it is best to apply general purpose and power relays only in applications where load voltage (or counter emf) and current is in excess of the arc voltage and current ratings of those contacts.

Contact Protection

Perhaps the most popular method of quenching an arc between separating contacts is with an R-C network placed directly across the contacts. As the contacts just begin to separate and an arc ignites, load current feeding the arc will be shunted into the capacitor through the series resistance, depriving the arc of some of its energy. As a result, arc duration will be shortened and material loss will be minimized.

Figure 1. Contact Protection Diagram

Theoretically, the ideal arc suppression method would simply be a capacitor placed directly across the contacts. However, with no resistor in the circuit, when the contacts make, there is nothing to limit capacitordischarge current. This nearly instantaneous discharge current can generate a brief, but severe arc that may cause welded contacts, depending on contact material and characteristics. Thus, the resistor is necessary to limit capacitor discharge current. However, there is one drawback. That is, the resistor tends to isolate the capacitor from the very contacts the capacitor is supposed to protect. Because of this, the amount of resistance should be kept as small as possible.

Many relay users are unfamiliar with the selection of a capacitor for arc quenching service. To begin with, AC differs from DC in that AC crosses zero 120 times per second for 60 Hertz service while DC, of course, is continuous current. In AC service, the capacitor need not be as large as in DC service because the AC arc will extinguish at a zero crossover point. In DC service, the capacitor must continue to shunt load current sway from the contacts until the contacts separate far enough apart for the arc to extinguish.

Capacitor Selection

Assume a DC application of 28 volts, 5 amperes. Further assume an R-C network is needed that will result in contact voltage of perhaps 15 volts 1 msec. after the contacts have separated. Since the value of resistance should be as small as possible, a 2 ohm resistor might be chosen. At 2 ohms, peak capacitor discharge current will be 14 amperes at time zero. Depending on contact material and size, this 14 amperes may be quite acceptable for such a short period of time.

Contact voltage—that is, arc voltage—at any given instant of time is simply the sum of the voltage drop of the resistor and the capacitor voltage. Select a capacitor voltage of, say, 10 volts. The remaining 18 volts must appear across the 5.6 ohm load and the 2 ohm resistor. Thus, instantaneous capacitor current is:

and the voltage drop of the 2 ohm resistor is 4.8 volts. Arc voltage, therefore, one microsecond after contact separation is 4.8V + 10V = 14.8V, or about 53% of supply voltage.

To determine the size of capacitance needed, the basic equation for capacitor voltage may be used:

ec = E(1 - ε -t/RC)

Rearranging the equation to solve for capacitance gives 1.1 µfd.

and the voltage drop of the 2 ohm resistor is 4.8 volts. Arc voltage, therefore, one microsecond after contact separation is 4.8V + 10V = 14.8V, or about 53% of supply voltage.

To determine the size of capacitance needed, the basic equation for capacitor voltage may be used:

ec = E(1 - ε -t/RC)

Rearranging the equation to solve for capacitance gives 1.1 µfd.

and the voltage drop of the 2 ohm resistor is 4.8 volts. Arc voltage, therefore, one microsecond after contact separation is 4.8V + 10V = 14.8V, or about 53% of supply voltage.

To determine the size of capacitance needed, the basic equation for capacitor voltage may be used:

ec = E(1 - ε -t/RC)

Rearranging the equation to solve for capacitance gives 1.1 µfd.

Where:

t = 1 µsec.

ec = 10 volts = capacitor voltage at time t.

E = 28 volts (for AC, use peak value).

R = 2.0 ohms.

The next question concerns capacitor construction. Can the capacitor withstand discharge surge currents? When the contacts close, the capacitor will discharge through the resistor. For a 1 µfd. capacitor and a 2 ohm resistance, the time constant is: R x C = 2 x 1 µfd. = 2.0 µsec.

To determine discharge di/dt:

where; .63 is the capacitor voltage loss during one time constant of 2.0 µsec.

This di/dt isn’t very severe and a wide variety of capacitors should be able to withstand it. However, the di/dt of a 5 ampere 240 volt AC application would be 107A/ µsec. at peak of the AC line—that is, 340 volts; and capacitor selection* should be made accordingly.

Of course, di/dt may be lowered by a larger value of resistance to limit capacitor discharge current even more. But, the greater the value of resistance, the less effect the capacitor has on the arc.

Other Arc Suppression Methods

For quenching DC arcs in certain applications, relays are available that have a permanent magnet located in close proximity to the contacts. The magnet repels the DC arc, thereby stretching the arc and causing it to extinguish quickly.

Some relay users connect a diode across the inductive load to prevent countervoltage from reaching the contacts. When the relay contacts open, the storedenergy of the inductance recirculates through the diode, not through the arc. While this is an acceptable method of protecting the contacts, it does result in lengthened hold-up time of the inductive load. For those applications that cannot tolerate lengthened hold-up time, a resistor may be placed in series with the diode. The resistor does, however, lessen the effectiveness of the diode and, usually, a compromise must be reached by trial and error.

By using a zener diode in place of the resistor, hold-up time is greatly reduced. This is because the diodes cannot turn on until the voltage across them equals the sum of their voltage drops.

In some circuits, space is at a premium and there may not be sufficient room for a zener and a regular diode. In such circuits, some designers use a metal oxide varistor. The MOV performs in a manner similar to back-to-back zener diodes. And, since the MOV is a bidirectional device, it can be used in both AC and DC circuits.

An added benefit of arc suppression is the minimization of EMI. An unsuppressed arc between contacts is an excellent noise generator. Such noise can be troublesome to sensitive components in a circuit, or within the RFI field. In worst-case conditions, EMI can cause unwanted turnon of IC logic gates, SCRs, and triacs, and can cause damage to other semiconductor devices.

*Suggested capacitor types are metalized foil and film foil. Check capacitor specifications for dv/dt and di/dt ratings.

Notes

- Measure the current inrush of the circuit to be switched before specifying the relay.

- Never parallel relay contacts to double the contact rating. Unless the relays are specially adjusted, they will not pick up and drop out simultaneously. Even if they were to be specially adjusted, they would not hold this adjustment over life.

- Paralleling Form C contacts may result in an unwanted makebefore-break arrangement. Contacts rated low level to 2 amps may be used to switch a 2 amp load. Once having done so, however, they cannot be used to switch reliably a low level load.

- In a circuit comprising a series of open relay contacts (AND logic), all but the last set of contacts to close will be dry. Likewise, in a circuit comprising a series of closed contacts, all but the first to open will be dry.

- The use of many relay contacts in series may be limited by total circuit contact resistance.

- A “low level” circuit that pulls a capacitive inrush current or develops an inductive counter emf is not low level. Worst case circuit conditions dictate contact rating, not steady state conditions.