Measuring linear position with string pots

A string potentiometer, sometimes also known as a string pot, a draw wire senor, a string encoder or a yo yo pot, is a cable actuated position sensor used to detect and measure linear position and velocity using a flexible cable and a spring-loaded spool.

String potentiometers, also known as a cable actuated position sensor, use a stainless-steel measuring cable wrapped around a spring-loaded spool. Similar to using a tape measure, the body of the sensor is bolted to a fixed position at one end of the stroke while the free end of the steel cable is attached to the moving object. An internal rotary sensor mated to the spool tracks the position of the cable as it is pulled out and retracted along the stroke. The tension spring keeps the cable taut even under the most demanding conditions and unlike rod-type linear sensors, cable position sensors do not require precise alignment and can retract into much tighter spaces.

Product Features:

String Potentiometer Portfolio

- Industrial packages with measurement ranges up to 43 meters for indoor and outdoor environments

- Analog voltage outputs including: 4-20mA, voltage divider, 0-5V, 0-10V, ±5 Vdc, and ±10 Vdc

- Digital outputs include: CAN bus J1939, CANopen, and incremental encoder

- Rugged metal housing as well as plastic packages for compact, economical applications

- Open frame designs for OEM needs with tight space requirements

- Precision packages to 0.05% accuracy and 0.02% repeatability for test and measurement

- Custom design and mounting options available

Typical Applications

- Automotive maintenance lifts

- Oil drilling equipment

- Surgical robots

- Surgical tables

- Water management

- Gate positioning

- Vehicle suspension and crash testing

- Space launch vehicle testing

- TV and film special effects

- Amusement park rides

- Overhead cranes

- Factory automation

How do string pots work?

In order to take measurements, the transducer's body is mounted to a fixed surface and the stainless steel cable is attached to the movable object. As the object moves, the transducer produces an electrical signal that is proportional to the cable's linear extension or velocity. This signal can then be sent to a display, a PLC or data acquisition system.

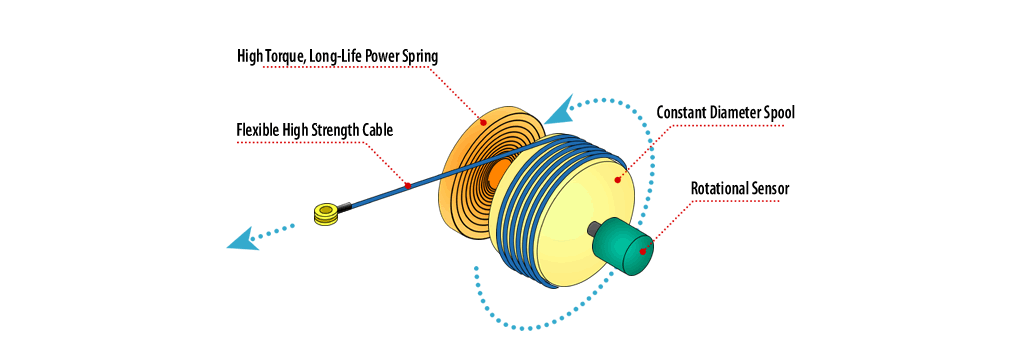

String potentiometers or cable-extension transducers (CETs) are composed of four main parts:

- measuring cable

- spool

- spring

- rotational sensor

Inside the transducer's housing, a stainless steel cable is wound on a precisely machined constant diameter cylindrical spool that turns as the measuring cable reels and un-reels.

To maintain cable tension, a spring is coupled to the spool. The spool is coupled to the shaft of a rotational sensor (an encoder or potentiometer). As the transducer's cable extends along with the movable object, it causes the spool and sensor shafts to rotate. The rotating shaft creates an electrical signal proportional to the cable's linear extension or velocity.

What types of output signals are available for a string potentiometer?

- Potentiometric (voltage divider)

- 0 to 10 volts DC

- 4-20 mA (2-wire)

- 0-20 mA (3-wire)

- Incremental encoder (Quadrature)

- Absolute encoder (contact us for details)

- RS232/RS422 communications

- DeviceNET®

- CAN bus J1939

What are the advantages of string pots?

Measuring the movement and position of objects is easy with string pots. String potentiometers can be installed in minutes, fitted into precarious or tight areas and they do not require perfectly parallel alignment. They also offer great flexibility, a small size to measurement ratio and they cost less than rod or wand-type measurement devices. String pots can be used in a wide variety of applications including industrial factory automation, high-tech medical devices, structural and automotive testing, die-casting or injection molding, hydraulic cylinder control and more.

What measurement ranges are available?

TE Connectivity offers full stroke range for string potentiometers from 0-2 inches up to 0-1700 inches (140 ft). If you have questions or need help selecting a specific model, please don't hesitate to contact us and one of our applications engineers would be glad to help.