Trend Insight

Improving Safety Performance in Cobots with Torque Sensors

Learn more about TE Connectivity’s (TE) torque sensors are improving safety performance in cobot applications.

Authors:

Arthur Vignolles, Product Development Engineering Manager, TE Connectivity

Ricardo Garcia, Product Manager - Force & Torque Sensors, TE Connectivity

Increasing Efficiency and Profitability with Cobots

As Industry 4.0 evolves, the use of more sophisticated robots, as well as advanced automation and control systems within industrial applications has become more common as companies continue their pursuit to increase efficiency and profitability. The advancement of automated technology has helped drive the development of collaborative robots. Collaborative robots, or cobots, are robots that can work alongside or with humans. These cobots are intended to interact with and assist workers as opposed to being standalone automated equipment with little to no human interaction. Historically, this limited interaction was due to safety concerns and the fact that humans and robots were not able to work together effectively and efficiently.

Today, cobots offer much greater flexibility in the workplace since protective cages are no longer needed for safety purposes and cobots have been developed to work seamlessly with humans and can perform tasks together thatneither humans nor robots could do on their own. This flexibility also helps increase return on investment (ROI) due to increased productivity and the reduced labor costs. These cobots can also handle complex or dangerous tasks

that humans either cannot complete or cannot perform safely. For example, cobots have the capability to perform surgery with a degree of precision and steadiness that is beyond the capabilities of even the best human surgeon. On the safety side, cobots can handle toxic materials and operate in environments that are not suitable for humans.

From product manufacturing operations to industrial packaging applications - and everything in between - cobots play a significant role in increasing productivity within the workplace. As companies continue to find new ways to integrate cobots and the benefits of utilizing cobots becomes better understood, this is leading to enormous growth in their deployment in factories and manufacturing facilities. According to the International Federation of Robotics (IFR), 22,000 cobots were installed in 2020 – a 11,000 increase from 2017. Additionally, global collaborative robot sales grew more than 25% since 2018 even though the overall industrial robot market observed a pandemic-induced slowdown. In terms of future growth, in the China market, cobot sales are expected to grow by 30% in the next 5 years. With this increase in the use of cobots, there has been a focus on regulations that can confirm a safe work environment and to protect personnel working alongside these cobots.

As safety requirements for cobots have been developed and expanded, technologies to help monitor and control cobots are being integrated into these machines. One example of this is a torque sensor that monitors the mechanical torque in a variety of the rotational pivot points on a cobot. The torque sensor is based on an integrated MEMs load cell that can translate mechanical torque to a digital output signal that is proportional to the torque applied. These torque sensors are used within cobots to detect conditions where the torque level is high enough that it could potentially harm a human in a collaborative application of where the torque level could damage the cobot itself.

The TE safety torque sensor starts with a one-piece flexure that is designed to translate rotational torque into mechanical strain. Piezoresistive strain gages are attached to the flexure areas and assembled in a Wheatstone bridge configuration such that the mechanical strain can be translated in mV/V output. Two small PCBs house an ASIC and other electrical components. The raw mV/V signal is compensated, amplified and digitized in an I2C format and that data is available on the bus. Depending upon the application, a torque threshold can be established that will allow the cobot to shut down before any humans are injured or before any damage occurs to the cobot itself.

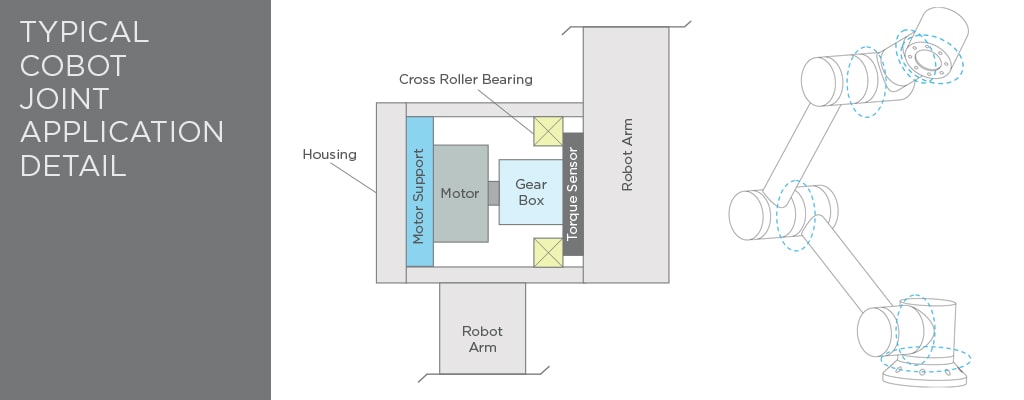

Safety torque sensors are typically integrated into the joint units of the cobot. The joint unit is a complete system and typically includes one or more angular sensors, as well as a motor and gear box. The joint unit drives the movement of each arm of the robot while the torque sensor is used to sense torque within the motor and gear box. The level of torque is used by the control circuitry to shut down the joint to prevent harm to the arm itself or, if being used collaboratively, the corresponding worker.

The trend of using torque sensors in cobot applications has been driven by the benefits that torque sensors provide to the system. Torque sensors allow for a faster response time and improved accuracy which leads to safer and more reliable cobot system s as well as increased human safety. Using a torque sensor in each arm joint allows direct detection of external force or torque exerted on the arm, rather than relying on complex calculations derived from motor currents. This enables a very fast stop on contact, and therefore can allow faster arm motion in collaborative situations where forces on any human contact must be limited. A further benefit is found when the cobot is operating in compliant mode. "Active" compliance allows the arm to be guided by hand (lead-through programming), simplifying the process of teaching the cobot new tasks. Direct detection of joint torque enables smooth and precise control of arm motion as it is guided.

TE safety torque sensors have been designed to provide accurate torque data while minimizing cross load errors (axial load, radial load and tilting moment) and can act as a sealing wall in a gear box. To comply with functional safety requirements up to ISO13849 Category 3 PL d, the design is based on a dual channel system and includes other features to detect any safety related failure. TE’s torque safety sensor is leading the way to improved safety and reliability in cobots as those machines continue to drive the evolution of Industry 4.0.