White Paper

SENSORS FOR MEDICAL PUMP APPLICATIONS

As the need for medical advances increase, sensing technology will continue to be the foundation to evolve the medical industry into a more connected, reliable and safe operation.

INTRODUCTION

Electronic systems in medical equipment, devices and probes rely on sensor signals as a basis for control activities, accurate diagnosis and treatment. Those systems are evolving to include more sophisticated capabilities while maintaining or improving their reliability. They are becoming more intuitive to use and there continues to be a push towards more mobile and connected medical products. Additionally, even though the healthcare industry has been slower to adopt the Internet of Things (IoT) technologies than other industries, the Internet of Medical Things (IoMT) is poised to transform how we keep people safe and healthy especially as the demand to lower healthcare costs increases.

These trends have increased the overall demand for sensors in medical products and devices, but it is also pushing those sensors to be smaller, faster, more accurate and more reliable. And for most manufacturers, budgets are limited, meaning low-cost components are ideal. Therefore, sensor innovations reaching the market need to feature smaller form factors while maintaining high functionality and affordability.

Sensors play a critical role in a wide range of medical functions including various medical pump and flow applications. An infusion pump is a type of medical pump device that delivers fluids, such as nutrients and medications, into a patient’s body in precise and accurate prescribed volumes over a specified time. These types of medical pumps are in widespread use in clinical settings such as hospitals, nursing homes and in-home settings since they offer significant advantages over manual administration of fluids. These advantages include the ability to administer very small doses, confirm programmed volumes and reducing employee workload due to automated administration.

Because infusion pumps are frequently used to administer critical fluids, including high-risk medications, pump failures can have significant implications for patient safety. Many infusion pumps are equipped with safety features, such as alarms or other operator alerts that are intended to activate in the event of a problem. For example, some pumps are designed to alert patients and staff when air or another blockage is detected in the tubing. Some newer infusion pumps, often called smart pumps, are designed to alert the user when there is a risk of an adverse drug interaction, or when the user sets the pump’s parameters outside of specified safety limits.

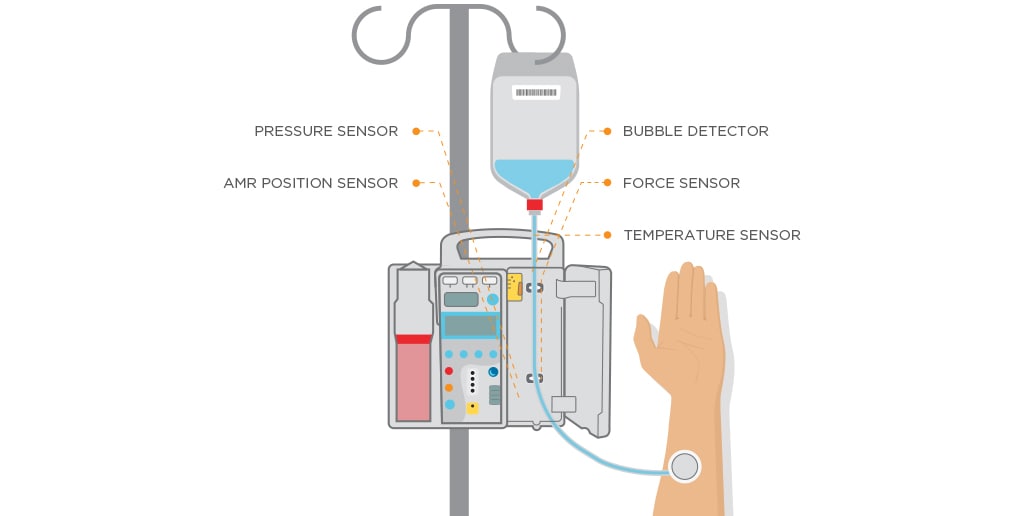

Within traditional and smart pump applications, sensors are key components in controlling and monitoring infusion pumps. They are designed to provide occlusion detection, monitor fluid flow, provide feedback for motor control and in some instances, sense the temperature of the IV fluid being administered. The figure below illustrates the potential locations of sensors employed in a typical infusion pump.

ILLUSTRATION OF POTENTIAL SENSOR INCLUDED IN TYPICAL INFUSION PUMP APPLICATION

There are many pump variables that need to be considered within medical pump applications. These variables include the volume of fluid but also the mode of infusion, which can be continuous, intermittent or patient-controlled. To ensure a correct flow of the fluid, force sensors are integrated into the pump to detect possible occlusions. The force sensor is typically installed under a portion of the tubing that is carrying the IV fluid. When a blockage occurs in a pump the tubing expands. A force sensor placed where the tubing meets the housing can detect this expansion by monitoring the force applied to the sensor by a section of the tubing. The sensor can trigger an alarm to alert the user if this expansion is detected. The same principles of operation can apply in infusion pumps and devices designed for operation by medical professionals in settings such as hospitals, hospices, and home-care. Expansion by monitoring the force applied to the sensor by a section of the tubing. The sensor can trigger an alarm to alert the user if this expansion is detected. The same principles of operation can apply in infusion pumps and devices designed for operation by medical professionals in settings such as hospitals, hospices, and home-care.

Although medical sensors for external use, such as in infusion pumps, tend to pose less of a technological challenge than implantable sensors, they still must meet tough requirements. Even as devices become smaller for increased portability, users still expect that these systems maintain functionality and accuracy. To design small yet accurate medical devices, component parts such as sensors must also offer robust features at a low cost. Additionally, reliability is essential for most medical pump applications, especially where critical fluids are being infused.

Force Sensor Technology

A force sensor is a sensor whose properties change when a force, pressure or mechanical stress is applied. A range of technologies can be utilized in the design and manufacture of a force sensor. TE Connectivity (TE) designs and manufactures force sensors for applications that require high performance or unique packaging, including medical devices and equipment. TE’s force sensors are based on a proprietary piezoresistive silicon strain gage (Microfused) technology, that combines durability and long-term stability in extremely low-cost packages. Force sensors (also referred to as “load cells”) are used in a variety of medical applications including infusion pumps. Other applications in the medical market include physical therapy, hospital beds (patient weight), surgical staplers, cardiopulmonary-resuscitation (CPR) assist machines for emergency medical treatment, as well as for oxygen tank monitoring.

Principles of Operation

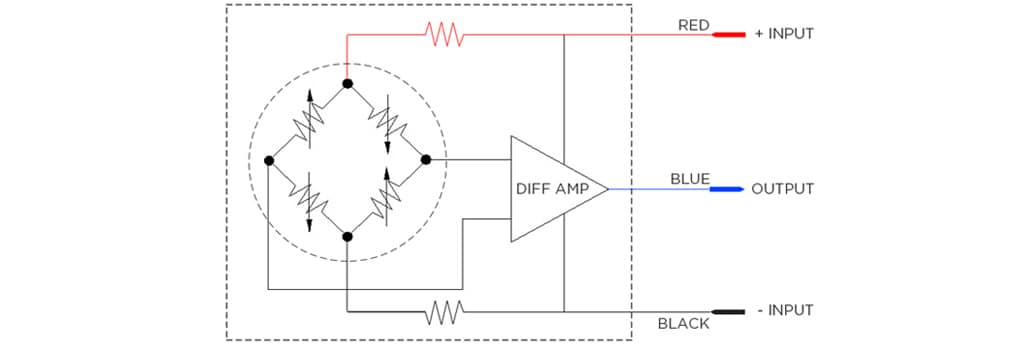

The Piezoresistive effect is widely used in sensor technology. The Piezoresistive effect is a change in the electrical resistivity of a semiconductor or metal when a mechanical strain is applied. A Piezoresistive force sensor contains several thin wafers of silicon embedded between protective surfaces. The surface is connected to a Wheatstone bridge, a device for detecting small differences in resistance. The Wheatstone bridge runs a small amount of current through the sensor. When the resistance changes, the current passing through the sensor also changes. The Wheatstone bridge detects this change and reports a change in pressure.

DIAGRAM OF A PIEZOERESISTIVE FORCE SENSOR WITH A WHEATSTONE BRIDGE AND AMPLIFIER

The proprietary TE Microfused manufacturing technology is based on micromachining silicon Piezoresistive strain gages and fusing them in a high-temperature glass-bonding process to a highperformance stainless-steel substrate. This mature and reliable process has delivered millions of force sensors and is a proven technology in a wide variety of medical applications. Microfused technology eliminates age-sensitive organic epoxies that are used in traditional load cell designs, thus providing excellent long-term span and zero stability. The cells measure force directly and are therefore not subject to lead-die fatigue issues common with competitive

designs, which use a pressure capsule embedded within a silicone gel-filled cavity. Operating at very low strains, Microfused technology provides an essentially unlimited cycle life expectancy, superior resolution, high frequency response and high over-range capabilities. Overall, Microfused force sensors have demonstrated their ruggedness and reliability in a wide range of medical devices.

Force Sensor Product Examples

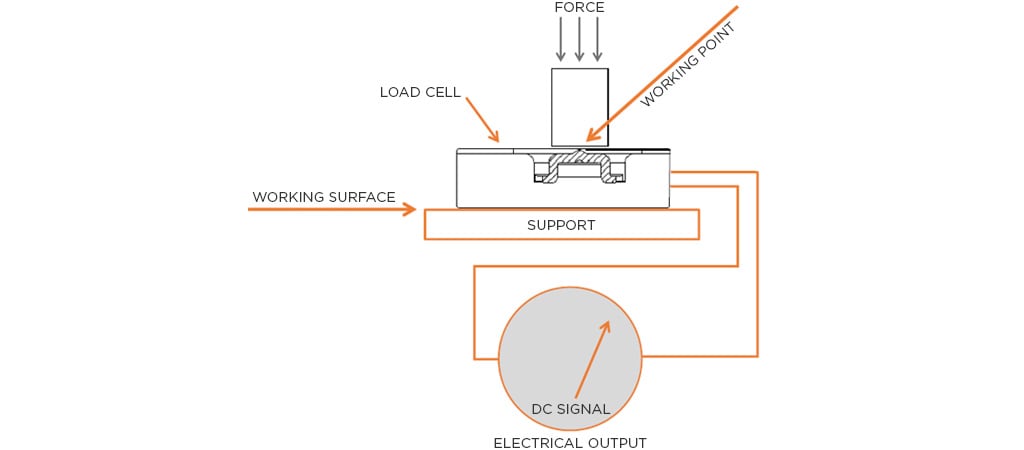

Some product examples are given to illustrate the principles of operation: In the FS20 force sensor, a disc-shaped load collector at the top of the cell is exposed to the mechanical stress caused by the fluid pressure in the pump. The metal load collector acts as a working point. It is deflected about 0.05 millimeters at rated load. A silicon Piezoresistive strain gage is fixed underneath the load collector. When the strain gage is exposed to stress by the elastic bending of the load collector, the resistance of the strain gage structure changes. This change is processed in an integrated circuit (IC) and is fed forward to the output lead. Zero and span of the cell are normalized to ensure interchangeability of the sensor. Miniature force sensors of the FS20 type offer a particularly attractive combination of electromechanical and economic features.

OPERATING PRINCIPLE OF A COMPRESSION LOAD CELL WITH PIEZO-RESISTIVE STRAIN GAGES

The RoHS compliant FS20 cell is available in two versions with either up to 750 grams of force or with up to 1500 g of force range. A high-level output, low noise, low off-center errors, and high overrange capability (up to 2.5x) in combination with fast and accurate results (± 1 % of span) plus temperature compensation for a range between 0° C and 50° C make the cell an excellent choice for pump monitoring. As the load collector deflection is very small, the cell has an essentially unlimited cycle life expectancy. The cell’s compact design (25.1 x 17.27 x 8.26 mm) allows for use in a broad range of applications with space constraints such as infusion pumps and other portable medical applications.

The FC22 miniature force sensor is based on the same operating principle; however, the working area is smaller to facilitate point load measurement. The cell’s form factor and cable connection offer different integration options. The FC22 cell is also available in a millivolt bridge version.

The FX1901 RoHS compliant compression sensor is used, for example, in physical therapy, to measure patient weight (scales), and in chiropractic and exercise equipment. Five measurement ranges span maximum loads from 10 lbf to up to 200 lbf (approximately 5kg to 100kg). The analog output signal relative to the input voltage is 20mV/V (20mV of output for every 1V of input voltage). This 1% accuracy load cell is based on a cost-effective design.

The FX29 is the latest innovative load cell product from TE and offers several new and improved features and due to many design changes, will be available at a significantly lower cost than previous load cell models. The FX29 is a miniature compression load cell designed for embedded force measurement applications. The sensor incorporates the high-reliability Microfused technology for the force elements and is offered in ranges from 10lbf to 200lbf. The FX29 has expanded the types of output types that are available and includes mV, amplified and digital output options. The incorporation of digital circuitry provides greater overall system accuracy and the low measurement ranges available allow for its use in a broader range of applications. High over-range protection safeguards the sensor from surges and spikes in the system and the low deflection with high output sensitivity means less stress on the sensing diaphragm which makes the FX29 ideal for demanding medical applications.

Bubble Detection in Infusion Pumps

Bubble detection is critical in applications such as infusion pumps, hemodialysis and blood flow monitoring where interruption in performance can be life-threatening. Ultrasonic bubble detectors are non-contact acoustic bubble and liquid detectors used to identify air bubbles and liquids in infusion tubes. They are widely used in applications such as liquid transfer and infusion in medical pumps, pharmaceuticals, industrial and scientific research.

TE’s AD-102 air bubble detection sensor for non-invasive, continuous monitoring of fluid for air bubble detection, uses ultrasonic technology to positively identify the presence of a break in flow of any type of liquid. With continuous self-diagnosis and flexibility in packaging, these sensors provide reliable and accurate bubble detection for critical applications such as infusion pumps.

Bubble Detection Technology

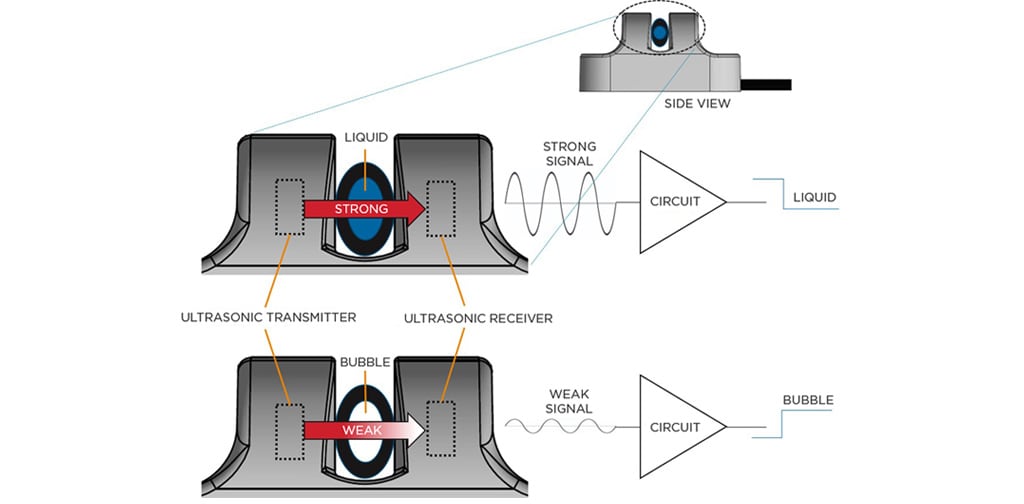

As shown below an air bubble detector such as TE’s AD-102, is designed to be installed directly onto the tubing that is used to infuse the liquid into the patient. The bubble detector contains an embedded piezo transducer that emits a tone burst ultrasonic signal. The signal passes through the tubing and it’s contents. A piezo receiver listens for the ultrasonic signal. Liquids transmit ultrasound efficiently, so a strong signal passes when only liquid is present in the tubing. Air bubbles do not transmit ultrasound waves efficiently, so the signal is weakened by any bubble in the liquid. An internal circuit measures the amplitude of the receiver signal and provides the appropriate output. The ultrasonic air bubble detector is non-invasive and has no direct contact with the liquid. The AD-102 can handle tube sizes from 3mm to 10mm and can be custom-designed to fit unusual tube sizes. The response time is less than 0.5msec, provides a 5V TTL output logic level and has an integrated LED that provides a visual indication if a bubble is detected.

ULTRASONIC AIR BUBBLE DETECTOR - HOW IT WORKS

The AD-102 also has a built-in self-diagnostic capability that continuously monitors the operation of the sensor. The sensor can be operated in any position with liquid flowing upward, downward, or at any angle. Gravity has no effect on the detection capability.

Other Sensors in Infusion Pumps

The designs for infusion pumps are becoming more sophisticated and additional features and diagnostics are being added. This will require the use of additional sensors as well as sensors with improved performance. Two other areas in medical pumps where sensors have been utilized include position sensors for motor feedback and diagnostics and temperature sensors for the monitoring and control of infusion liquids.

Anisotropic Magnetoresistive (AMR) position sensors are precise and contact-less devices that measure the changes in the angle of a magnetic field as seen by the sensor. TE’s magnetic sensors offer robust non-contact position measurements in harsh environments. For example, the unique features of the AMR effect allow the measurement of sub-micrometer displacements in precision linear encoders. The AMR technology is also successfully used for presence detection, such as the endpoint detection in pneumatic cylinders. This AMR technology provides a low-cost, robust technology for monitoring either linear or rotary motion and allows precise position feedback for a range of motors that drive most infusion pumps. These durable products are designed to provide enhanced output accuracy for smooth motor control and their small size often reduces replacement costs and allows for design into many compact, automated, lower-cost assemblies.

On the temperature sensor side, it has been shown that intraoperative intravenous fluid administration and blood product transfusion have considerable effects on body temperature. Thus, it is important to monitor and control the temperature of fluids. A range of medical fluid warmers are often utilized when fluids are infused intravenously, and temperature sensors are integrated as part of these systems to monitor and control the temperature of the fluid. While many of the warming units are separate and external to the infusion pump, there is a push to integrate this option into new infusion pump designs.

TE Connectivity designs and manufactures a wide range of temperature components and assemblies that have been used in a broad range of invasive and non-invasive medical applications to monitor everything from core body temperature to the temperature of cryogenic gases used for angioplasty balloons.

Summary

TE designs and manufactures a broad range of sensors utilizing many different technologies that are critical for the monitoring and control of electronic systems for a range of applications in the medical field. One of the major areas within patient treatment is medical pumps and, more specifically, infusion pumps. TE sensors are applied in the following areas of infusion pumps:

- Force sensors to detect occlusions to confirm there is no blockage in the tube that delivers medication to the patient.

- Air bubble detectors are capable of positively identifying the presence of a break in flow of any type of liquid.

- Anisotropic Magnetoresistive (AMR) position sensors monitor the angular or linear position of medical pump motors.

- Temperature sensors are used to monitor and control the temperature of infused liquids that are being delivered into a patient’s body.

Application Fields for Force Sensing

Medical device OEMs are seeking products that provide reliability, appropriate size (miniaturization), lower cost, and better overall performance. The many medical application areas of force sensing include:

- Ambulatory drug dispensing systems, man of which rely on force sensing as the primary sensor technology for feedback control.

- Surgical procedures are also rapidly improving, as low cost, high reliability force/torque sensing enables precise measurement. Staple machines and ocular surgery devices are being equipped with force sensors to enable quicker, more precise surgical procedures.

- Pumps used to irrigate and saline-flush sites for knee and shoulder surgeries increasingly use force sensing to optimize flow rate.

- Load cells are now widely used in saline drip weight measurement.

Applications for Bubble Detectors

Bubble detection is critical in applications such as infusion pumps, hemodialysis and blood flow monitoring. TE’s AD-102 air bubble detector offers:

- Self-diagnostic functions including power-on and continuous self-diagnosis

- Flexibility to be customized to fit any tube or pipe

- Integral electronics enabling compact product design with easy integration

- 20 years of proven performance with sensors sold around the world

TE designs and manufactures sensors for wide variety of medical applications. TE offers ISO13485 certification and FDA registration for various sensors and assemblies. Our global network of engineers provides application specific sensor design, from product concept through manufacturing. TE’ s dedicated medical sensor team offer rapid prototyping for fast paced product development and offer support throughout the product’ s lifecycle.

Microfused is a trademark.