Accelerating Innovation

Winning in today’s technology marketplace means developing an optimal solution, making the customer happy, and getting to market quickly. One of the quickest paths to reaching these results is 3D printing, a crucial technology for quickly turning ideas into fully functional prototypes that help teams test concepts early and iterate efficiently.

Authors:

Gregory T. Pawlikowski, Principal Development Engineer, Harrisburg Research Center

Jessica H. B. Hemond, Principal Development Engineer, Harrisburg Research Center

Ranjan D. Deshmukh, Staff Scientist, Harrisburg Research Center

Making functional prototypes begins with using engineering resins with the properties and ratings required, with a fabrication process similar to that used in end-product manufacturing. In 3D printing today, techniques mostly lack the material options and physical performance needed. This restricts a manufacturer’s capacity to directly print functional plastic parts. Despite this, manufacturers can leverage 3D printing to quickly fabricate mold tooling for making functional prototype parts, with the same material and process as a production part. This provides manufactures with four advantages, allowing them to:

- Complete testing for design verification

- Qualify parts for production worthiness

- Supply parts for customer evaluations

- Accelerate the process for product development

THE ALTERNATIVE: 3D-PRINTED MOLD TOOLING

Production mold tooling is typically made from multiple pieces, requiring high precision machining techniques to fabricate and assemble the tools. This usually requires a high part volume to justify the cost. Generally, this process is impractical for making small quantities of parts, especially when the design could change.

While quick-turn subtractive processes enable manufacturers to create simplified mold tooling, these use automated computer numeric control (CNC) milling machines, which often have issues with cutting-tool reach, particularly when there is a deeply recessed cavity as well as geometry limitations, such as inside corner radii. With this, subtractive processes can also involve long lead times and in the end, exceed expected costs.

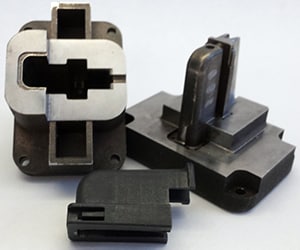

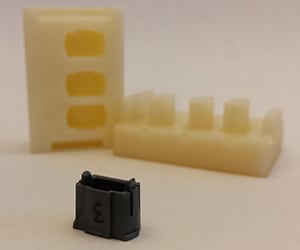

Fortunately, there is an alternative: 3D-printed mold tooling. This approach produces tooling that is usable in traditional molding machine and compatible with production-grade resins. Developed for a variety of 3D-printing techniques, this approach can include metal and plastic materials for the mold tooling. While machined metal tools have the advantage of providing very small features with high durability, 3D-printed tooling is complementary in that it offers enough resolution, thermal stability, and materials strength to generate small volume, rapid-turnaround molded parts.

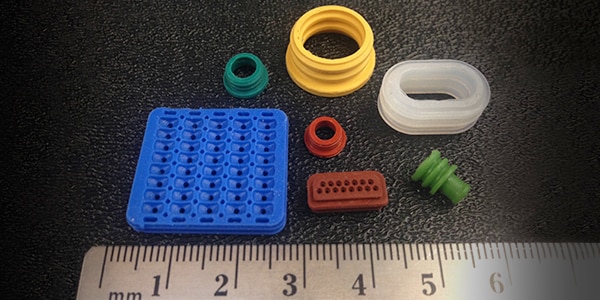

For example, there are numerous applications that require parts capable of withstanding harsh environment conditions. Making these parts means using high-temperature, engineering-grade resins, and requires attributes such as fine features, thin walls, and a high-level of complexity combined with tight tolerances. There are several challenges to successfully molding accurate parts from 3D-printed mold tooling. Our team at TE has identified and resolved several, including:

- Print resolution and accuracy

- Secondary finishing of printed mold tooling

- Mold insert durability

- Engineering resin type and processing conditions

- Molded part re-work

CHOOSING THE RIGHT PRINTER AND RIGHT MATERIALS

We have learned that to overcome these challenges, we must begin by choosing the right type of 3D printer and the right kind of mold materials. The resolution and print accuracy of printed molds are limited, and can vary depending on the printer and mold material used. We have found that stereolithography (SLA) printers – which typically cure a liquid resin material using a laser –provide both the highest accuracy (~ 0.02-0.05 mm) and the best feature resolution (down to 0.125 mm). This can also produce tooling with sharp, crisp features and corners.

Other important technologies include digital light processing (DLP) printing, which uses light projection technology, and monomer jetting printers, which can cure dispensed photopolymer resin droplets using broadband UV light. Powder-bed 3D-printing technologies – such as direct metal laser sintering (DMLS) – can achieve good accuracy and resolution, but produce a rough surface finish.

An important consideration is the secondary finishing of the printed molds and inserts, since it can add to the overall process cost and time. A rough surface finish not only reduces the surface quality of the molded part, but may adversely affect the release of the part during ejection from the mold. Photopolymer curing technologies (such as SLA and monomer jetting) provide relatively smooth surfaces that require low or negligible post-finishing operations.

Due to the inherent surface roughness of DMLS-printed metal tools, some degree of secondary machining is often required. However, if a rougher surface is allowable, less involved operations such as bead blasting or hand finishing are sometimes sufficient. Some surface roughness and stair stepping effects (on surfaces built at an angle) are unavoidable – even for polymer mold tooling – when using layer-by-layer printing (e.g., layer thickness 0.05 mm for SLA).

3D-printing technologies – including direct metal laser sintering (DMLS) – are key to TE’s ability to produce rapid tooling with good accuracy and resolution.

While surface roughness is the largest issue with DMLS printed metal molds, tool durability is the primary challenge for polymer molds. This is caused by polymers' inherently lower strength when compared to metals, especially when different thermal and mechanical properties are involved at the elevated molding temperatures and pressures. The mechanical and thermal properties of the polymer tooling ultimately dictate the number of successfully molded parts or number of shots.

These properties directly influence the survival of core features (especially for small size and or high aspect ratio cores) and may lead to premature mold-insert cracking or deformation. The insert cracking and deformation are particularly dictated by factors such as mold material strength at higher temperatures, mold material degradation in contact with hot polymer melt, coefficient of thermal expansion/thermal conductivity differences, and thermal shock.

Our team has identified the elements to choosing the right printer and mold material:

- Part geometry, smallest feature

- Production material to be molded

- Number of parts needed

There are other factors affecting success: It is crucial to establish the right conditions for the molding process and determine the modified mold design rules that are suitable for polymer molds.

Remember, the durability – and subsequent performance –of the polymer mold tooling is significantly determined by the engineering resin used for the molded part, the filler type (e.g., abrasive glass fibers tend to cause severe mold wear, versus unfilled resin), melt viscosity, and mold processing parameters. This can require adjustments to either the printing process, the model, or both, to ensure accurate part dimensions.

By using a printed metal tool, manufacturers can apply standard polymer processing and shrinkage values. To make this work for polymer molds, manufacturers may need to make process adjustments and mold design adjustments. Fully understanding the process and design adaptations will help you get the best result from this technology.

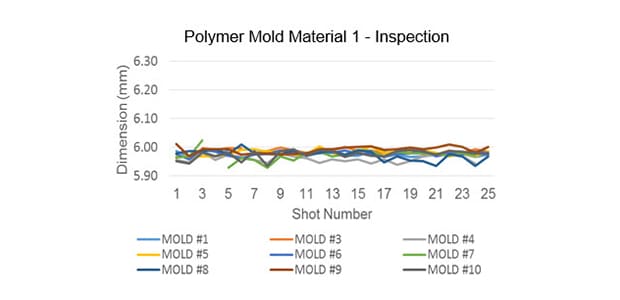

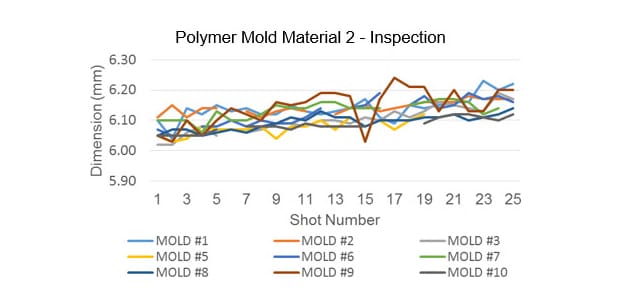

Not all polymer molds are equal in performance. Picking the right mold material is key for a successful implementation.

Across TE, we continuously develop and enhance our processes for fabricating polymer molds, with an eye toward deploying these across our full portfolio of products. This includes most materials in the resin pyramid and existing molding machines. By utilizing unique design and process advancements, we can overcome the traditional limits placed on printed tooling. With the right processes, we can not only print fine features but also reproduce those features in the molded parts. This includes molding with high-temperature materials such as liquid crystalline polymers (LCPs) in printed polymer molds. Any allowances that may be needed are dependent upon the technology being used.

Keep in mind that the performance of polymer mold materials varies greatly. When comparing different polymer mold materials, there are some clear advantages in durability and wear over repeated molding cycles. There is also some variance – based on polymer mold material – in the design adjustments needed to bring the mold to nominal dimensions, and within tolerance.

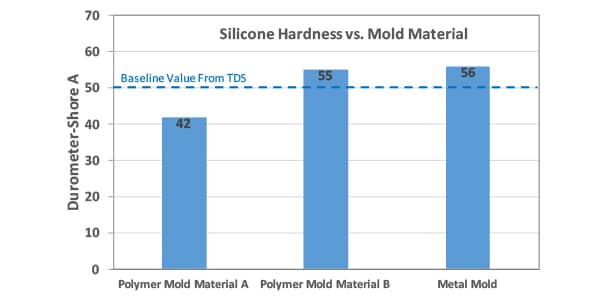

This technology is not limited to thermoplastic resins. We also use it to mold thermosetting resins, such as silicones, fluorosilicones, and other elastomers. Considering the cost and complexity of traditional silicone molds, there is a clear advantage in adapting a low cost, quick turn approach. As seen when molding thermoplastic resins in polymer molds, manufacturers may need to adjust the tool design and process. While it is also important to select the appropriate mold material, the objective is to make a tool that offers the performance of a traditional mold.

There is advantage in the turnaround time, which is often shorter than conventional machining methods. Not only is the printing process capable of producing results quickly (only a few hours in some cases), it can produce printed mold tooling that is usable with little to no secondary finishing. To minimize the cost and reduce production times, manufacturers can employ strategies for making the printed molds as small as possible.

While 3D-printed polymer molds often only produce a limited number of molded parts, the new technology uses additional printed molds to multiply the total number attainable. When needed, manufacturers can use 3D-printed metal molds to create a higher number of molded parts, under production processing conditions.

OUR COMMITMENT TO INNOVATION

At TE, we can apply this technology to most production resins in use. But there are some challenges to still overcome. Today, we are working to improve the durability of finer features and adapting the process to make larger scale products, for our energy or transportation portfolios. Currently, we are working with technologies that allow us to meet tight tolerances and fine pitch features, <0.4mm.

At the same time, we are making adjustments in design and processing when making parts greater than 12cm. By refining the mold design and process parameters, we can look to further deploy this technology over the full range of our portfolio.

Today, there is no single 3D-printing solution appropriate for producing all the many ranges of product geometries and volumes. When it comes to 3D printing, we operate a diverse suite of printing technologies that we run in-house. The breadth of our 3D-printing technologies is the result of our ongoing, long-term commitment – dating back to the late-1980s – to invest in technologies that leverage our broad capabilities and deep knowhow in mold tooling and molding, in ways that enable us to develop and test novel solutions for producing low volumes of functional prototypes. Everyday across our enterprise, we use these technologies to advance our internal expertise and collaborate across a global network of diverse engineers committed to accelerating innovation and adopting rapid tooling technology.