An MCON Family Case Study

White Paper

Can you have too much?

In this analysis, the authors look at the use of lubricant during the crimping process. They examine if the use of lubricant will degrade the mechanical or electrical performance of a crimp.

AUTHORS

Jessica H. B. Hemond, Principal Development Engineer, Harrisburg Research Center

Marcos Pajuelo, Senior Product Development Engineer, Application Tooling

Suvrat Bhargava, Senior Manufacturing and Process Development Engineer, Harrisburg Research Center

Introduction

TE Connectivity considers the use of terminal lubrication or oil to be an important component to ensure a consistent, high quality end crimp. [1] While not required for all crimps, past investigations have shown that lubrication can provide benefits in terms of reducing tool wear and corrosion. Additionally, lubrication can provide a greater consistency and uniformity in the crimping process. TE Connectivity’s research in this topic has been both substantial and varied. TE Connectivity researchers have studied various aspects of this technology from crimp type, the performance of solid versus stranded wires as well other factors, including contamination. [2,3] These factors were identified and studied to ensure that any variable that may influence the process or crimp, itself, was well understood. In the development of crimp tooling, this body of research has provided guidance to the development of reliable tooling.

It is understood through this prior work that terminal lubrication has an influence on crimp force. The addition of lubricant can result in a decrease of crimp force and impact the final crimp height. The end recommendations from this work include the use of crimping lubricants, adjusting the crimp height regularly and changing the crimp tooling when signs of wear are seen. These recommendations are not new to the industry, but with the passage of time the supporting data for these recommendations and the relationship to the known influence of crimp lubrication have become obscure. This effort relates the influence of crimp lubricant in creating a consistent high-quality crimp and ensuring consistent die tool performance.

However, the question remains as to what impact the lubricant may have if it migrates or is transferred from the outer die to the inner terminal. In the early 1960s AMP Incorporated researchers Zimmerman and Imswiler, examined the use of non-corrosive lubricants or fluxes within a crimp is benign and additionally may offer benefits in terms of improving crimp consistency. While this historical research provides general guidance to the acceptability of lubricant within the crimp area, the general practice is to apply to the outside barrel only. Given the evolution of common products and requirements over the past five decades, such as differences in the size, lubricants and environmental exposure, it is necessary to confirm and document this historical conclusion. The MCON 9.5 interconnection product family was chosen for this evaluation to determine if an excessive level of lubrication within the crimp itself will provide any drawback to the electrical or mechanical performance of the product. This product family was chosen in part because it was found to be developing burrs in the initial application testing. While this issue was resolved without the use of lubricant, lubricant would be a common solution to this problem. As such this family was deemed a good candidate for this additional investigation.

These recommendations are not new to the industry, but with the passage of time the supporting data for these recommendations and the relationship to the known influence of crimp lubrication have become obscure.

Procedure

Table 1 contains the products and associated crimp tooling. These were selected to compare both electrical and mechanical performance under three distinct conditions: no lubricant, standard application of lubricant, and excessive level of lubricant. In the third case, lubricant was intentionally introduced into the crimp barrel. This could be considered a worst-case situation where the lubricant application process is introducing an excessively high amount. The comparison of these three cases provides a baseline for the evaluation of TE Connectivity products and determines what, if any, performance aspects might be most susceptible to the introduction of an excessive amount of crimp lubricant.

Table 1: Sample Identification

One area of concern is the balance of good electrical and mechanical stability. The relationship between deformation and either electrical performance or mechanical performance is known. For our purposes, we consider crimp height to be a representation of the level of deformation introduced to the crimp. Work completed by Mroczkowski [3] and others confirms that either too little or too much deformation can result in poor performance in electrical and/or mechanical performance.

Since the optimized electrical performance does not necessarily align with the peak mechanical performance, a balanced approach to ensure both electrical and mechanical requirements are met is standard practice. [3] Since it is known that crimp lubrication can impact the crimp height and thus its deformation, it is important to consider the end performance related to its estimated deformation.

Two different OCEAN applicators were used to produce three sets of samples of each product. The first set of samples was produced using no lubricant, which is the standard use of these applicators. The second set of samples was produced using the standard lubricator assembly, which applies a small amount of lubricant to the external side of the wire barrel of the terminal. The third set of samples was produced using the lubricator assembly as done with the second set but adding manually an excessive amount of lubricant in the internal side of the wire barrel of the terminal before placing the wire. The lubricant used was Chemlube 1102 synthetic lubricant, available from Ultrachem, Inc.. [1]

The three sample sets were produced independently using the same bench terminator. Starting with no lubricant, followed by standard lubricant levels and ending with the excessive amount of lubricant. This order was determined to ensure that the tool was not exposed to any cross contamination from the previously produced samples.

A modified version of testing procedure TE 109-18079, rev. G was used as the baseline for the environmental testing, shown in Figure 1. Five samples were examined for each set and followed the process outlined in Figure 1. Crimp resistance measurements were made using a four-terminal measurement technique in accordance with IEC 60512-2-1, First Edition, 2002-02. Thermal shock testing was completed in accordance with IEC 60068-2-14, Edition 6.0, 2009-01. While humidity heat cycling was in accordance to IEC 60068-2-30, Third Edition, 2005-08, with the exception that final LLCR measurements were taken approximately 17 hours after specimens were removed from the chamber.

This testing allowed for the monitoring of the crimp resistance after 500 cycles of thermal shock followed by temperature/humidity cycling. The as-crimped and thermally cycled samples were also examined for mechanical stability using a comparison pull out force test.

Figure 1: Environmental Conditioning Base Protocol

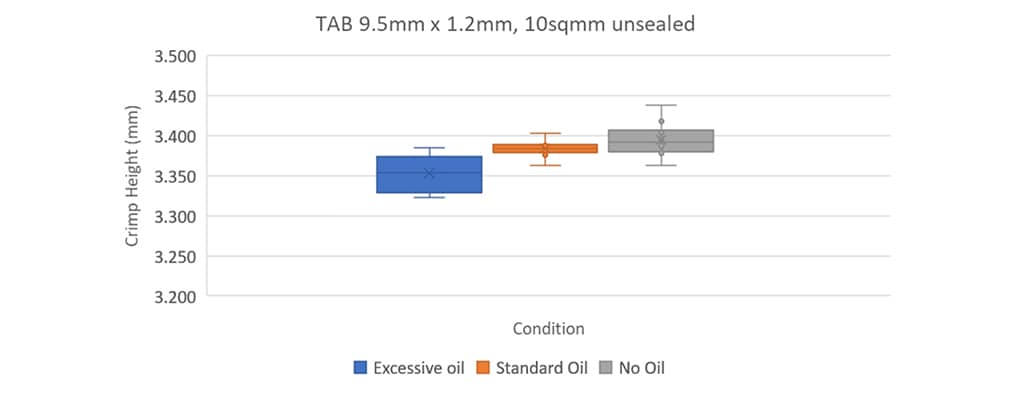

Once crimped, samples were measured using a crimp micrometer per TE instruction sheet 408-7424, rev S. It should be noted that TE commonly measures the crimp height via a mechanical cross section instead of a micrometer to qualify a new applicator tool. Since cross sectioning is a destructive technique, a micrometer was chosen to be used for this study. Because of the differences in crimp measurement method, the crimp height is compared between groups and not to the original crimp applicator validation. As can be seen from Figure 2, the use of lubricant can impact the crimp height.

Figure 2: Measured Crimp Height by Condition

The samples that were crimped with excessive lubrication have a lower crimp height than the other two groups. It is reasonable to believe that samples in this set have more deformation than the samples in the other set. This indicates that attention should be given to the pull-out force to ensure that these crimps have not exceeded the peak tensile force to the point where the pull-out force is dramatically reduced. When setting up and during periodic checks of the crimp applicator this variation of crimp height due to the influence of lubricant, or even tool wear during a longer use, should be monitored and adjusted to ensure a consistent crimp height.

Thermal Stability

Prior to the environmental exposure it was deemed prudent to understand any thermal limitations of the lubrication in use. TE Connectivity uses standard lubricants that have been formulated specifically for crimping and are available globally. [1] Figure 3, shows a Thermogravimetric Analysis (TGA) curve of the Stoner E807 lubricant, available from Stoner Incorporated. [1] Per prior TE work, Stoner E807 lubricant was developed as locally available version to Chemlube 1102 lubricant and as such is considered equivalent as both products would meet the requirements of the AMP formulated crimping lubricant, P/N 22014.

Figure 3: Thermal Stability of Stoner E807 Crimp Lubricant

TGA is a common technique to review the thermal stability of a polymer by measuring weight changes over time and temperature. This test heated a sample of the lubricant in a mixed atmosphere of Nitrogen and Oxygen and recorded any weight loss to determine if there were any indications of degradation. This testing showed that once the lubricant exceeds 160oC, it will slowly start to lose weight; indicating that some low level of degradation has begun. This sample continued to be exposed to high temperatures until 200oC and held in an isothermal mode for over five minutes. The total loss during this test was approximately 5% by weight. This testing has shown that the recommended lubricant is thermally stable until 150oC. Time, as well as temperature is a factor for degradation. This testing identifies the temperature at which the material is susceptible to degradation. While loss can be expected when temperatures exceed more than 160oC, it is relatively minor for short term excursions up to 200oC. Longer term stability at elevated temperatures may still be problematic and is best considered in terms of impact on mechanical or electrical performance. It is important to note that not all lubricants would be expected to have the same performance either thermally or in actual use.

Electrical Stability

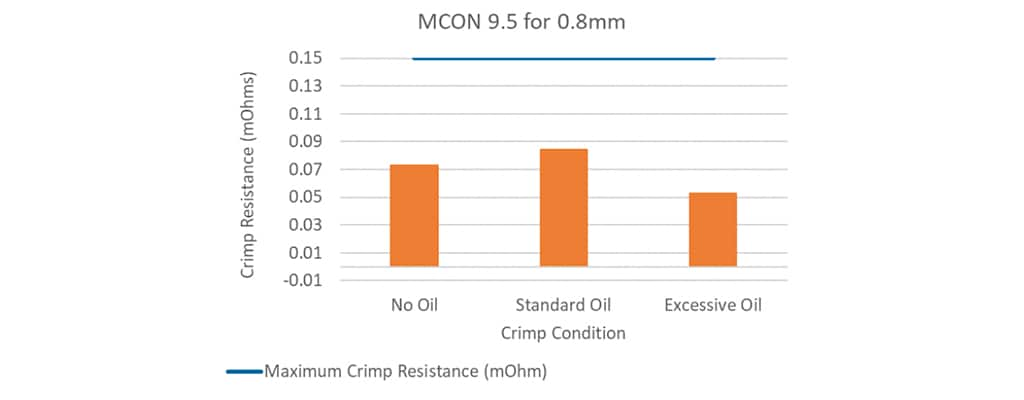

There are two criteria to ensure that electrical stability is met. The first is that no one reading should equal or exceed 0.15mOhms. The second is that the delta resistance should be less than or equal to 0.09mOhms. Figure 4a, shows the maximum crimp resistance that was measured. Both for the MCON 9.5 and TAB 9.5mmx2mm products, the maximum reading was below 0.09mOhms and 0.12mOhms, respectively, meeting the base requirement. The delta values of these products also met the baseline requirements, Figure 4b.

Figure 4a: Initial Crimp Resistance – Maximum

For the MCON terminal in terms of maximum resistance, the standard and excessive oil levels bounded the range of the three samples while the performance of the no lubricant and standard application were comparable and smaller than the delta resistance of the excessive oil.

Figure 4b: Average and Maximum Delta Crimp Resistance after Environmental Exposure

Comparing the performance of these products at the differing levels of lubricant shows variable behavior. For the TAB 9.5mmx1.2mm, the different levels of lubricant showed relatively consistent maximum resistance reading, while the standard oil showed a marked improvement over either of the other two conditions. For the MCON terminal in terms of maximum resistance, the standard and excessive oil levels bounded the range of the three samples while the performance of the no lubricant and standard application were comparable and smaller than the delta resistance of the excessive oil. Given the limited sample size explored in this study, no clear trends or conclusions can be reached other than the fact that an excessive amount of lubricant used during the crimping process does not prohibit the crimped product from meeting the product’s electrical requirements.

Mechanical Stability

The mechanical stability of the samples tested in the as crimped as well those exposed to the stated environmental conditions, met the base crimp tensile pull out force requirement. Calculated as the mean minus three standard deviations (Mean-3SD) greater than or equal to 450 N. Additionally, the minimum recorded pull-out force also met the minimum requirement. Crimp retention for the various sets both as crimped/received and after environmental exposure can be seen in Figure 5. As expected, environmental exposure reduces the pull-out force. The reduction in pull-out force is not unexpected given not only the possible changes in the lubricant but also the crimp barrel and wire. Beyond that aspect, there is no clear rule that would describe the behavior between products or conditions in terms of failure mode. The MCON 9.5 for 0.8mm product showed no change in type of failure before or after environmental exposure. However, the TAB 9.5mmx1.2mm product did see both a further extension in the wire prior to breaking and in some extreme cases, the blade breaking at the fixture prior to the crimp failing. This variation is best demonstrated by the standard lubricant set. Of the five samples tested in the as received condition all failed in the wire region; exhibiting both wire pull out and ultimate wire breakage. In contrast of the five standard lubricant samples conditioned and then tested, only one exhibited this failure mode. The remaining four exhibited a longer wire extension without a complete separation of the crimp from the cable. For the non-lubricated samples, a similar change in failure mode was seen. While all the as received samples showed the same failure modes as the samples with standard lubrication, only one sample of the conditioned samples shared the same failure mode. The resulting four showed breakage in the blade portion of the tab and not the crimp. This change in failure mode is important to consider but does not change the fact that regardless of failure mode, the mechanical performance of the material meets minimum requirements.

Figure 5: Crimp Retention Before & After Environmental Exposure

From the electrical and mechanical testing of this product line, the use of oil, even an excessive amount placed inside the terminal, can be considered negligible in terms of the product meeting the end use requirements.

Conclusion

The use of lubricant during the crimping process, in addition to its influence on the lifespan of the crimp tooling, may influence the crimp height. However, in this examination of the MCON family neither the electrical nor mechanical performance were seen to be reduced to an unacceptable level when using either a standard level of lubrication or even an excessive amount. From the electrical and mechanical testing of this product line, the use of oil, even an excessive amount placed inside the terminal, can be considered negligible in terms of the product meeting the end use requirements. Additionally, it is important to note that the lubricant used should be properly chosen. Not all lubricants would be expected to have the same performance as those examined here. While attention to the sensitivity of a product to the crimp height as well as the potential change in mechanical failure mode would be suggested areas to review when considering a different product family, comparing these results with the prior work, it is reasonable to believe that the conclusions reached for this product family can be extended.