Automotive Connectors for Harsh and Exterior Applications

TE Connectivity (TE) manufactures the MCON Interconnection System for electrical and electronic applications in various harsh environment motor vehicle applications.

150°C

Up to 150°C for engine applications

48V

48V ready in the new generation of MCON connectors

IPx9k

Weather-proof rating for exterior applications

NEW - MCON 1.2 NextGen and NextGen Plus 1-row Sealed Locking Lance Connector Series

• Sustainability – Significant reduction of carbon footprint (~39% CO2) by design and further carbon footprint reduction with bio-massed balanced solution.

• Automation - Integrated secondary lock latch with large contact area for automatic locking. QR code with best-in-class track and trace and lower cycle time.

• Performance - Improved and highly robust solution offering high vibration (SG4) and quality. Improved CPA design offering additional robustness and improved ease of use.

• Versatile - Versatile solution using the same interface to serve multiple applications in the vehicle. Fully compatible with MCON standard and Gen2 series and validated according to LV214 and USCAR2.

• Future-Ready - 48 Volt ready and ready for automation.

• Improved Ergonomics - Easier to handle with increased surface and bigger latch to disengage.

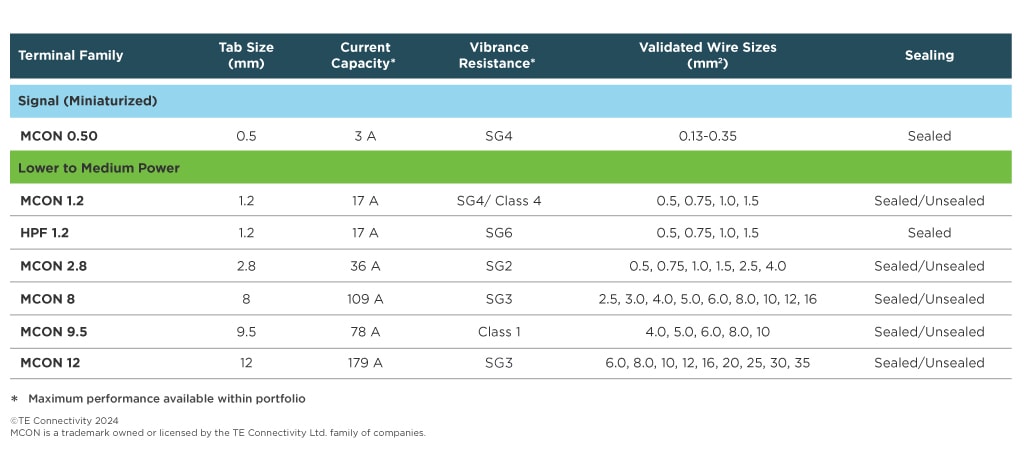

MCON Terminals

High Performance, High Reliability

MCON is a series of contact systems commonly used for electrical and electronic applications for passenger cars and commercial vehicles. The contact design meets standardized blade sizes and interface requirements of the automotive industry. Except the miniaturized MCON 0.50 contact system, all contacts follow the two-piece contact design strategy to separate the electrical from the mechanical performance.

The MCON contact series is available for sealed and unsealed applications. The new generation MCON connector system offers receptacle and tab housings with capability for waterproofing and resistance to conditions of extreme vibration. For a fast and economic termination process, TE Application Tooling offers a vast portfolio of application equipment.

Benefits

MCON Terminals

- High performance copper alloy

- Redundant contact point technology for higher reliability

- High vibration level support to meet future requirements

- Overstress protection of the contact springs

- Contact box with polarization and secondary locking feature

- Protected locking lance (Except MCON 0.50 – clean body version)

- Sealed and unsealed version

- -40°C up to 150°C temperature range

- -40°C to 180°C with innovative surface technology available

- Three directional secondary locking access

Find Receptacle and Tab Terminals

The MCON and HPF receptacle terminals and tabs are available in various sizes and configurations (clean body / locking lance). Find the right size for your interconnection system needs.

MCON Connectors

Designed to take on vibration and mechanical stress

The new generation MCON connector system offers receptacle and tab housings with capability for waterproofing and resistance to conditions of extreme vibration. The system is designed for electronic and electrical applications in motor vehicles, where vibrations and mechanical stress, in the long term, can affect the quality of the contact system.

Features

Housings and Connectors

- CPA (Connector Position Assurance) capability

- High reliability status - supported for long term use

- High vibration level supported

- Excellent design to avoid quality problems, while reducing manufacturing and service cost

- Integrated secondary locking device delivered in pre-locked position

- Wire-to-Wire sealed and unsealed connectors (SWS)

- Polarization, several keyings

- Modular housings possible due to same level of secondary lock

Find MCON Connectors and Housings

The MCON series of connectors are available in a variety of sizes and configurations. Various configurations are available for temperatures up to 150°C.

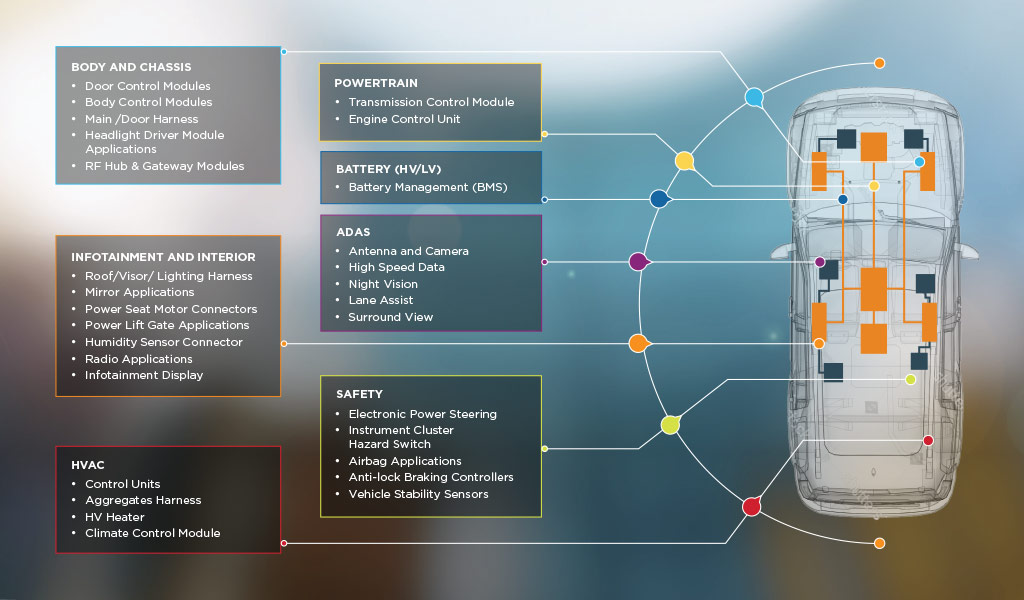

MCON Applications