FIND A SUBJECT MATTER EXPERT BY TREND OR TOPIC

Industrial Cobots and Robotics

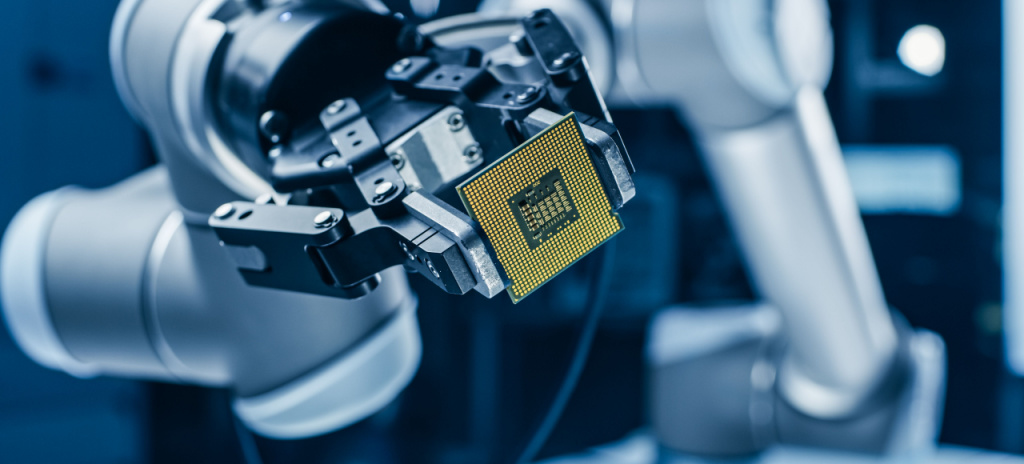

While industrial robotics have long been essential in large factories, a significant new trend is the increasing use of cobots, or collaborative robots. Unlike traditional industrial robots that usually operate apart from factory workers, cobots, as the name implies, are implemented to work alongside employees, assisting them with or completing a variety of tasks. Pressures to increase productivity and reduce costs, along with shortages of skilled labor have contributed to the increased use of cobots. And due to their smaller size, flexibility, and cost-effectiveness, cobots can often be added to existing production lines not only in larger factories, but in small to mid-size industrial facilities as well. They not only help to increase the output of the production line, but they also can be used for more difficult or challenging tasks, improving the work environment for the employee and reducing the risk of accidents or injuries. Cobots, however, have only been made viable due to relatively recent technological advances, including the development of sophisticated sensors to monitor and control their movements and their proximity to their environment, and to ensure that they safely operate along side people. Cobot manufacturers and their industrial customers rely on TE technology, such as torque sensors, to allow them to operate safely and efficiently and our subject matter experts are available to discuss how these technologies work today and will evolve in the future.

Contact us

For trade media, to speak with a TE Transportation or Sensors Group expert, please contact:

Deanna McCoy

deanna.mccoy@te.com