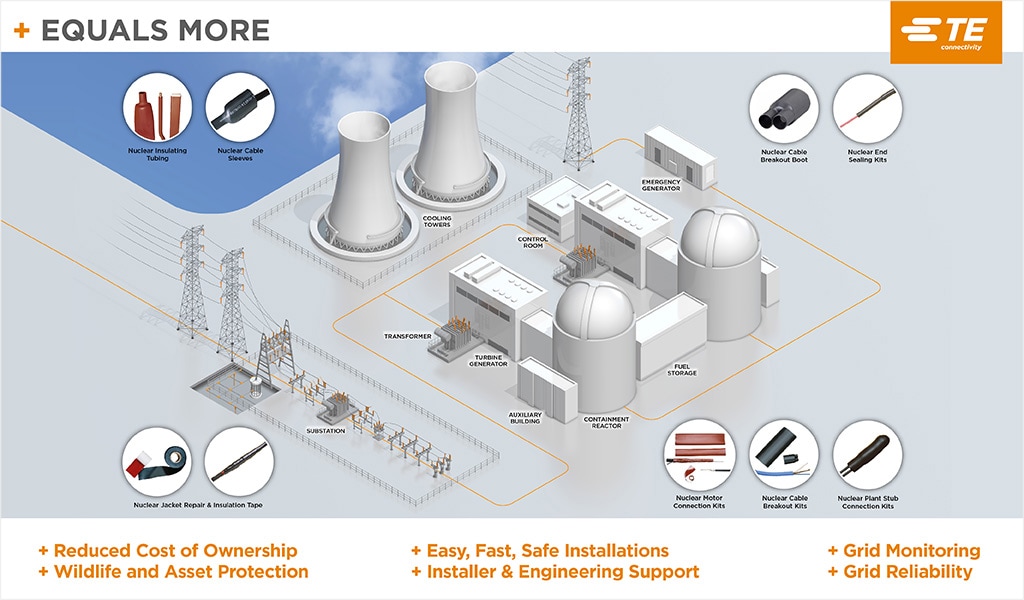

Get an overview of our highly reliable cable accessories.

Download Portfolio HighlightsReliability is Essential

You have a critical role to play in providing more environmentally friendly electricity. Nuclear energy is an emission-free, dependable, ‘always-on’ power source which today supplies 10% of global electricity.

Our nuclear cable accessories meet the specific needs associated with protecting many of the 200,000 connections required in the construction and maintenance of your plants. Our nuclear cable accessories have been subjected to the Loss of Coolant Accident Test (LOCA) and High Energy Line Break Test (HELB) to establish their performance in a postulated nuclear accident environment. Our products are designed and manufactured under a quality assurance program that complies with 10 CFR 50 Appendix B and several other national and international standards.

Our Raychem heat shrink components and kits, seal and insulate reliably electrical connections in your nuclear power plants. Manufactured from heavy-wall, flame-retardant, crosslinked polyolefin and precoated with a nuclear grade adhesive, these products are designed to withstand the radiation levels and temperatures found inside the containment buildings of nuclear stations.

Supporting the Move Towards a Carbon-Free Future: Our Nuclear Industry Credentials

380+

worldwide reactors powered with our Raychem nuclear cable accessories

25+

countries with nuclear plants using our Raychem nuclear cable accessories

40+

years’ experience in the nuclear market

One Connectivity Partner

As your critical partner to the nuclear industry, our mission is to support, sustain, and solve your electrical connectivity needs by providing essential components that are compliant with the demanding requirements of US and global regulatory laws.

Our reputation is built on over 40 years of experience in the nuclear market. In fact, our Raychem revolutionary heat shrink technology pioneered radiation crosslinking in the 1950s and has been supplying cable accessories to the nuclear power industry since the 1970s. Today, most safety-related Class 1E splices are made using our Raychem heat shrink components.

Download our nuclear line card for an overview of the solutions we offer for nuclear plant applications.

Design

In addition to supplying base components (tubing and molded parts), we design and manufacture a wide variety of kits to seal and insulate specific connections in your nuclear plant. These kits have the added advantage of being pre-designed to be consistent with the type-tested designs and contain all the components required for your installation.

Advantages of pre-designed kits:

- Design details and calculations are reviewed and documented

- Multiple checkpoints exist in the documentation to verify proper kit selection

- Traceability is provided and maintained

- Detailed installation instructions provide step-by-step guidance

Qualification Testing

Our nuclear products are designed to perform in extreme environments and are tested beyond the design basis conditions of your nuclear power plants.

Nuclear Equipment Qualification (EQ) for products involves compliance with industry-accepted standards, including IEC/IEEE 60780-323, IEEE 383, and other international standards. The materials used in many of TE’s products have been tested and proven to perform their intended function for the lifetime of the plant typically 40 to 60 years at 90°C. We use many recognized methods to confirm the lifetime, including the Arrhenius method for accelerated aging of plastics. These materials are then used individually as components, as tubing for simple splices, or in various combinations called ‘kits’ that are designed for your complex applications.

Our Class 1E safety-related harsh environment products are type-tested in the intended use configuration and in worst-case conditions by our own or independently certified laboratories. The results of these tests are presented in Energy Division Reports (EDR) which are used for EQ purposes in our certificate of conformance/compliance.

As a recognized manufacturer of the IEEE Nuclear Standards Certification Program, end-users are assured that the equipment qualification testing, reported test results, and regulatory compliance have been verified by an extensive, independent technical auditing team, approved by the IEEE Conformity Assessment Program. This provides confidence and assurance that the products purchased meet all your necessary standards of quality and safety.

Train

We offer training for Raychem nuclear-qualified products to your installers, inspectors, and engineering personnel. These sessions cover the basic elements of material science, heat shrink polyolefin technology, specific product functions, and hands-on installation.

Certification

All our nuclear-qualified products are supplied with a Certificate of Compliance / Conformance.

Class 1E (K1) Nuclear Qualified LOCA/HELB Type Tested Cable Accessories

-

Nuclear Cable Sleeves WCSF

Made of flame retardant, heavy-wall tubing, designed for nuclear applications. Our Raychem WCSF cable sleeves are designed to electrically insulate, mechanically protect, and environmentally seal electrical connections.

-

Nuclear Plant Splice Kits NPK

Provides an environmentally-sealed and mechanically-protected electrical splice insulating system. Our kits are designed to meet a variety of electrical splicing requirements.

-

Nuclear Jacket Repair & Insulation Tape NJRT / NWRT

Wraparound products are ideal when access to the cable end is not possible. Made from the same material as WCSF tubing, our Raychem nuclear tapes are designed to repair cable jacket damage for Class 1E circuits, subject to accident conditions.

-

Nuclear Plant Stub Connection Kits NPKV

Insulate and seal V-type stub connections to a variety of electrical connections in small boxes or conduit bodies (condulet) where installation space is minimal.

-

Nuclear Motor Connection Kits NMCK

Designed for low voltage motor connections, our Raychem NMCK kits are available in V-stub, in-line, ‘Y’ and ‘H’ configurations.

-

Nuclear End Sealing Kits NESK

Designed to environmentally seal cable ends and spare conductors.

-

Nuclear Cable Breakout Kits NCBK

Designed to environmentally seal cable jackets to prevent moisture ingress into the cable.

-

Nuclear Terminal Block Replacement Kits NTBR

Insulate and environmentally seal smaller wires that cannot be adequately sealed using a terminal block.

Class 1E Medium Voltage Tubing & Kits

-

Nuclear High Voltage Terminations NHVT

Provide a system for terminating and sealing medium voltage cables from 5 kV to 15 kV. Our Raychem NHVT terminations have been tested for use on Class 1E circuits subjected to accident conditions (MSLB/HELB).

-

Nuclear Trifurcation Kits MOD-3-NHVT

Designed to trifurcate 3/C by adding rejacketing tubing to the phase conductors and a sealing breakout boot to the jacket of the 3/C cable. Once installed, the three 1/C cables are then terminated with standard NHVT kits.

-

Nuclear Motor Connection Kits NMCK8

Insulate and seal connections in Class 1E motors up to 5/8 kV, our Raychem NMCK8 kits are available for in-line, V-stub, and ‘Y’ configurations. Our NHVT kits are available to terminate the feeder cables, prior to installation of the NMCK8.

-

Nuclear Heat Shrink Insulation Tape HVBT-RN

Sealant-coated, general-purpose heat shrink tape used to insulate straight and bent bus bars in retrofit Class 1E (5-15 kV) non-accident applications, where tubing cannot be used.

-

Nuclear Busbar Insulating Tubing BBIT-N

Heavy wall bus insulation tubing for use on straight or bent bars where clearance reduction is required. Our Raychem BBIT-N tubing is rated for 15 kV applications and has been tested for Class 1E insulated connections under HELB conditions.

-

Nuclear High Voltage Splice Kits NHVS

Designed to splice and environmentally seal medium voltage cables rated for 5/8 kV. NHVS kits can be used with a variety of shield configurations. The splice incorporates our stress control components and shield continuity across the splice.

Class 1E Cable Fasteners, Hardware & Accessories

-

Fiberglass Sleeves

Used in Raychem splice kits to protect the outer WCSF tubing from sharp edges and to keep the connection area free of sealant.

Our Fiberglass Sleeves have been tested for Class 1E service subject to accident conditions.

-

Ground Clamp Accessory Kits GCA

Our GCA clamp uses a constant force spring that is installed by simply wrapping it around the cable over the ground strap. The clamp is supplied in kit form along with a solder-blocked, tinned copper braid.

-

Hardware (Nuts, Bolts, Washers)

Almost every cable or conductor must be terminated and/or spliced. Often, these electrical connections are secured with fastening hardware such as machine screws, bolts, washers, and nuts.

Class 1E Molded Parts (Non-Accident Environments)

-

End Cap

Our range of Raychem class 1E end caps are suitable for cables in non-accident environments.

For accident environments, our end caps must be used as part of a kit.

-

Breakout Boot

Our range of class 1E breakout boots are suitable for cables in non-accident environments.

For accident environments, our breakout boots must be used as part of a kit.

-

Molded Shape

Our range of class 1E heat shrink molded parts and shapes are suitable for cables in non-accident environments.

For accident environments, our molded shape must be used as part of a kit.