-

Product Listing

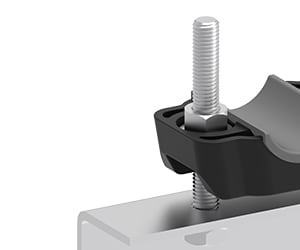

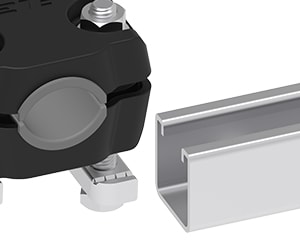

Cable Cleats made from V0 Flame-Retardant Polymer

- RAYCHEM

Our Cable Cleats from V0 Flame-Retardant Halogen-Free Polymeric material offer a highly reliable retention system against electromagnetic forces in short circuit events for cables and terminations in LV, MV and HV applications. Their compact, stackable design is ideal for installation where space is limited.

Product Features

-

Number of Cables to be Mounted : 1 | 2 | 3 | 4

-

Compatible Cable Diameter Range (mm): 15 – 26 | 15 | 19 – 30.48 | 26 | 26 – 38 | 27 – 42 | 30 – 42 | 38 – 50 | 38 | 39 – 54 | 42 – 54 | 50 – 63 | 50 – 75 | 51 – 79 | 54 – 67 | 63 – 75 | 67 – 79 | 75 – 100 | 75 – 89 | 76 – 104 | 79 – 93 | 89 – 104 | 93 – 108 | 100 – 135 | 101 – 139 | 104 – 120 | 106 | 108 – 124 | 120 | 135 – 175 | 139 – 179 | 175 – 220 | 179 – 224

-

Compatible Cable Diameter Range (in): .59 | .59 – 1.023 | .74 – 1.18 | .75 – 1.18 | 1.02 | 1.02 – 1.5 | 1.06 – 1.65 | 1.18 – 1.65 | 1.48 | 1.5 – 1.97 | 1.53 – 2.12 | 1.65 – 2.12 | 1.97 – 2.95 | 1.97 – 2.48 | 2 – 3.11 | 2.12 – 2.63 | 2.48 – 2.95 | 2.63 – 3.11 | 2.95 – 3.5 | 2.95 – 3.93 | 2.99 – 4.09 | 3.11 – 3.66 | 3.5 – 4.09 | 3.66 – 4.25 | 3.93 – 5.31 | 3.97 – 5.47 | 4.09 – 4.72 | 4.17 | 4.25 – 4.88 | 4.72 | 5.31 – 6.88 | 5.47 – 7.04 | 6.88 – 8.66 | 7.04 – 8.82

-

Bolt Hole Centers (mm): 56 | 60 | 64 | 80 | 81 | 82 | 100 | 107 | 126 | 138 | 139 | 160 | 163 | 176 | 187 | 217 | 220.6 | 258 | 261 | 290

-

Bolt Hole Centers (in): 2.2 | 2.34 | 2.52 | 3.15 | 3.19 | 3.23 | 3.93 | 3.94 | 4.21 | 4.96 | 5.43 | 5.47 | 6.3 | 6.42 | 6.93 | 7.36 | 8.54 | 8.68 | 10.15 | 10.27 | 11.41

-

Height (Installed) (mm): 53 | 62 | 87 | 90 | 100 | 106 | 110 | 120 | 124 | 130 | 138 | 140 | 150 | 158 | 170 | 171 | 177 | 180 | 188 | 200 | 220 | 221 | 231 | 237 | 240 | 253 | 260 | 270 | 287 | 299 | 300 | 340 | 390

-

Height (Installed) (in): 2.08 | 2.44 | 3.42 | 3.54 | 3.93 | 4.17 | 4.33 | 4.72 | 4.88 | 5.1 | 5.11 | 5.12 | 5.43 | 5.51 | 5.9 | 6.22 | 6.69 | 6.73 | 6.96 | 7.08 | 7.4 | 7.87 | 8.66 | 8.7 | 9.1 | 9.33 | 9.44 | 9.96 | 10.23 | 10.26 | 10.63 | 11.3 | 11.77 | 11.81 | 13.38 | 15.35

-

Bolt Size : 1 x M10 | 1 x M12 | 2 x M10 | 2 x M12 | 2 x M16